- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1400*730*1200mm

-

Weight:

-

1100 KG

-

Drilling Depth:

-

Max.80m

-

Mobility:

-

yes

-

Maximum lift height::

-

45 meters

-

Maximum depth::

-

80 meters (262 ft)

-

Maximum drilling diameter::

-

300mm (12 IN)

-

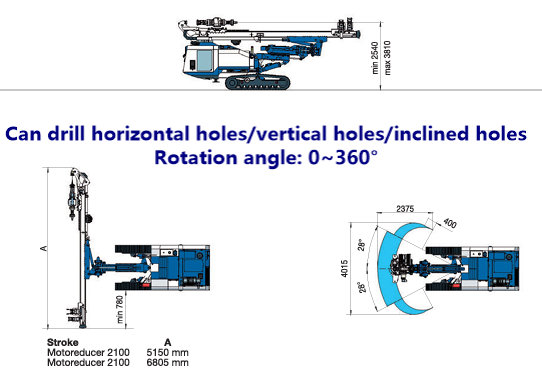

Drilling angle::

-

0~360°

-

color::

-

yellow/blue/OEM

-

Max.Lift force::

-

45kN

-

Air consumption::

-

9-12m3/min

-

Rotation torque::

-

3600N.m

-

P*hone:

-

0086 155 1568 2190

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YUGONG MACHINE

-

Voltage:

-

diesel engine

-

Dimension(L*W*H):

-

1400*730*1200mm

-

Weight:

-

1100 KG

-

Drilling Depth:

-

Max.80m

-

Mobility:

-

yes

-

Maximum lift height::

-

45 meters

-

Maximum depth::

-

80 meters (262 ft)

-

Maximum drilling diameter::

-

300mm (12 IN)

-

Drilling angle::

-

0~360°

-

color::

-

yellow/blue/OEM

-

Max.Lift force::

-

45kN

-

Air consumption::

-

9-12m3/min

-

Rotation torque::

-

3600N.m

-

P*hone:

-

0086 155 1568 2190

Product Description

Suitable for a variety of working conditions:

drilling in clay, silt, sand or quicksand formations, and can also be used in loose, broken, rockfill and other rock formations.

Specification

|

Model

|

YG40

|

YG50

|

YG70

|

YG90A

|

|

Drill depth(m)

|

10~60

|

10~60

|

25~70

|

25~100

|

|

lift height(m)

|

2-5

|

5-10

|

10-18

|

18-35

|

|

Hole diameter(mm)

|

90~150(rock)

|

90~180(rock)

|

90~230(rock)

|

90~250(rock)

|

|

Air consumption(m³/min)

|

9~12

|

9~12

|

9~12

|

9~12

|

|

Drill rod(mm)

|

φ76*1500 φ89*1500

|

φ76*1500 φ89*1500

|

φ76*1500 φ89*1500

|

φ76*1500 φ89*1500

|

|

Rotary torque(N.m)

|

1700

|

3600

|

5200

|

6800

|

|

Lifting force(kN)

|

27.5

|

45

|

65

|

65

|

|

Hydraulic pressure(Mpa)

|

16

|

16

|

16

|

16

|

|

Electric motor(kw)

|

7.5+4

|

22

|

25

|

30

|

|

Weight(kg)

|

750

|

1100

|

1300

|

1400

|

|

Dimension(mm)

|

1400*730*1200

|

1400*730*1200

|

1400*730*1200

|

1400*730*1200

|

Successful Cooperation cases

The anchoring rig

is mainly used in the landslide and dangerous rock mass anchoring projects in the prevention and control of various geological disasters in hydropower stations, railways and highway slopes, especially suitable for high slope rock mass anchoring projects, and also suitable for construction of urban deep foundation pit support, anti-floating For bolts and foundation grouting reinforcement engineering holes, blasting holes for blasting engineering, high-pressure jetting piles, tunnel pipe shed support holes, etc., the power head can be slightly changed to facilitate all-round construction.

Main drilling methods: conventional drilling with down-the-hole hammer, pipe drilling, and auger drilling. In the drilling construction practice of various complex formations and different drilling methods, its excellent drilling performance has been recognized by the majority of construction units and peers.

In recent years,

the construction pile machinery manufacturing industry has achieved rapid growth and has a good development momentum. Under the favorable state of increasing infrastructure investment, the industry has an average annual growth rate of

nearly 30%

. Benefiting from the continuous development of the global economy and the pull of fixed asset investment , the implementation of the strategy of revitalizing the equipment manufacturing industry and other favorable factors, especially the construction of a number of high-speed railways, highways, high-rise buildings, super bridges and other projects do not require piles and deep foundations for support, which has led to the use of piles in recent years. The sharp rise has driven the rapid development of the global pile machinery industry. At the same time, with the gradual increase in the construction volume of environmental protection, ecological construction, gardening, and greening construction, pile machinery must have a wider and wider stage.

Product Advantages

High-strength crawler chassis

Equipped with a turntable and optional rotary jetting module, making the rig more adaptable to complex construction conditions

Drilling Rig Rotary Platform

Driven by dual hydraulic motors, the output torque is large, which improves the drilling stability of the drilling rig and improves the work efficiency.

root canal drilling tool

It can support arm opening in unstable formation, with fast drilling efficiency and good hole quality

Our service

Whole process guidance

With more than 20 years of service experience,

Please provide your procurement budget, drilling height/depth/bore diameter, construction conditions? We will provide the most suitable model.

Provide a full set of construction method and equipment training

After-sales service system

Support customization

Extensive spare parts service

Support sea, land and air transportation

We can ship products to every corner of the world. If you need, we also support a series of tedious tasks such as customs clearance and tail end delivery.

Hot Searches