- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

/

-

CrO Content (%):

-

/

-

SiC Content (%):

-

≥88%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Silicon Carbide

-

Brand Name:

-

LKT

-

Fe2O3(%):

-

≤2.0

-

F.C(%):

-

≤3.0

-

Bulk Density(g/cm3):

-

≥3.15

-

Application:

-

Grinding,Refractory

Quick Details

-

SiO2 Content (%):

-

/

-

Al2O3 Content (%):

-

/

-

MgO Content (%):

-

/

-

CaO Content (%):

-

/

-

CrO Content (%):

-

/

-

SiC Content (%):

-

≥88%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Silicon Carbide

-

Brand Name:

-

LKT

-

Fe2O3(%):

-

≤2.0

-

F.C(%):

-

≤3.0

-

Bulk Density(g/cm3):

-

≥3.15

-

Application:

-

Grinding,Refractory

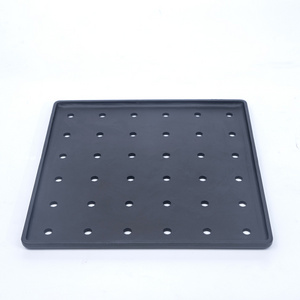

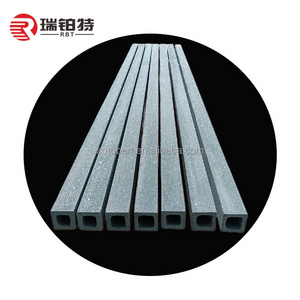

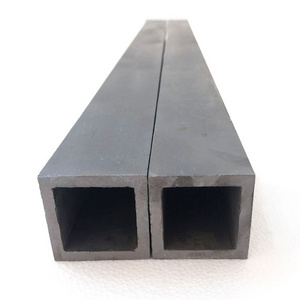

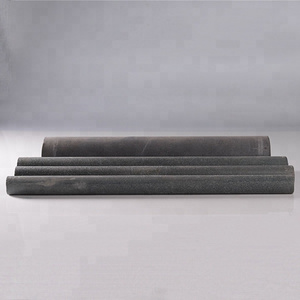

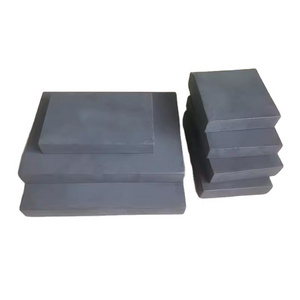

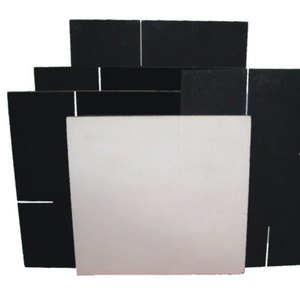

Long Keter 88/97 Refractory Silicon Carbide For Rotary

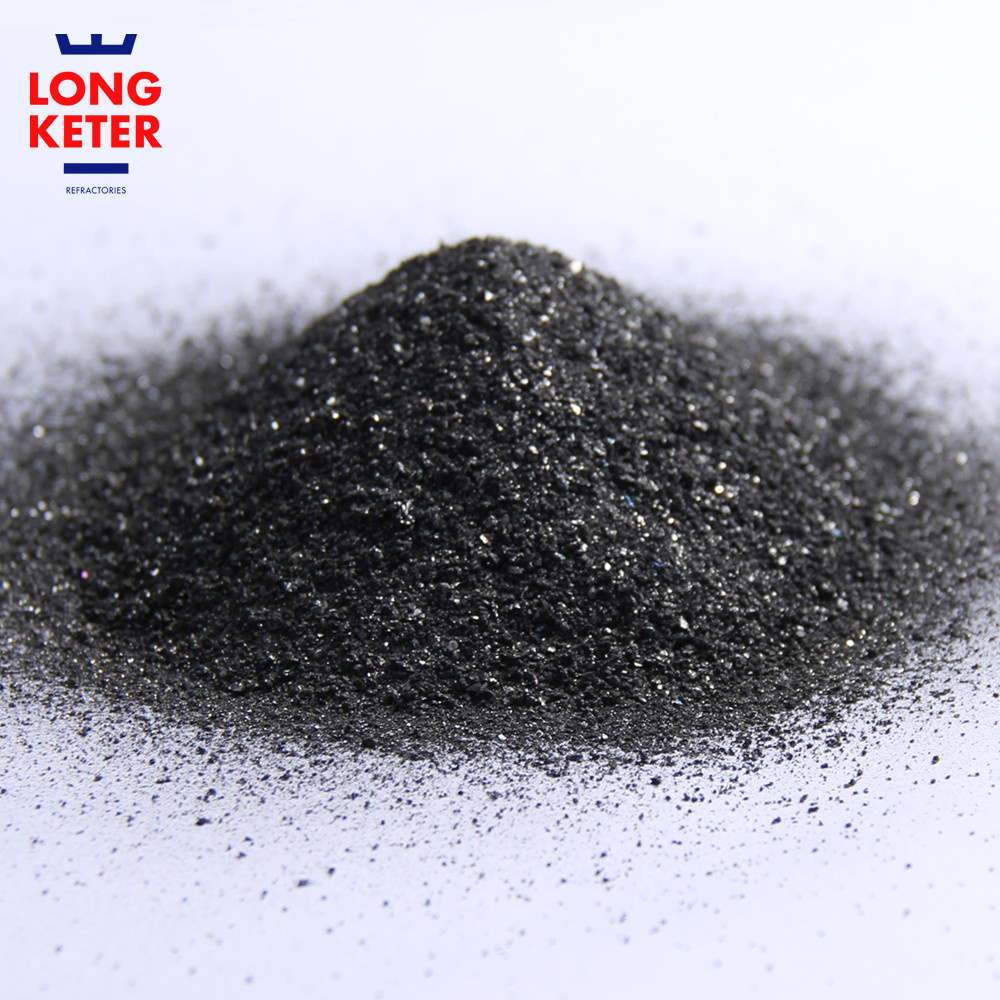

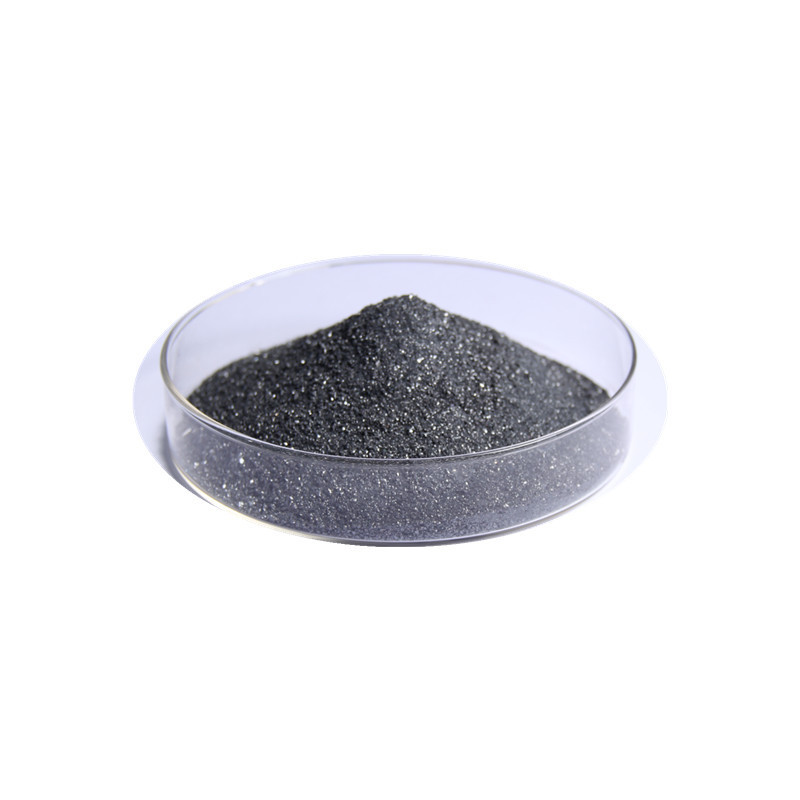

Black silicon carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke as its main raw marterials .Its hardness is between fused alumina and synthetic diamond.Mechanical intensity of it was higher than fused alumina .It is brittle and sharp has electrical and heat conductivity in some degree.The abrasives made of it are suitable for working on cast iron,non-ferrous metal,rock, leather,rubber,etc.It is also broadly used as refractory material and metallurgical additive.

Silicon Carbide gets the Mohs hardness grade of 9.5,it is only the second to the world's hardest diamond(Grade 10),has excellent thermal conduct properties,is one kind of semiconductor,oxidation resistance at high temperature.Due to the features of chemical stability,high thermal conductivity,thermal expansion coefficient,abrasive resistance,silicon carbide are mainly applied in four main areas:functional ceramics,senior refractory material,abrasives and metallurgical materials.

Lower grade silicon carbide is a very good reducing agentmit is able to promote the production pace of steel-smelting,controlling relevant chemical composition,and improve the quality of steel;In addition,silicon carbide are also widely used in the production of heating elements like silicon carbon rod.

We offer tabular alumina size as below:

Sand size:0-1mm,1—3mm

Fine powder:200mesh 325mesh

Customized size is available

Product Data

| Range Of Grit Sizes | Chemical Composition(% By Weight) | |||

| SIC% | F.C% | Fe2O3% | Density(g/cm3) | |

| SIC98% | ≥98.5 | ≤0.2 | ≤0.4 | ≥3.4 |

| SIC97% | ≥97.5 | ≤0.3 | ≤0.5 | ≥3.3 |

| SIC90% | ≥90 | ≤2.5 | ≤2.0 | ≥3.15 |

| SIC88% | ≥88 | ≤3.0 | ≤2.0 | ≥3.15 |

Applications

For abrasive: Lapping, Polishing , Coatings, Grinding , Pressure blasting.

For refractory: Refractory media for casting or metallurgical linings ,Technical Ceramics.