- Product Details

- {{item.text}}

Quick Details

-

Ambient temperature: -20°C~71°C:

-

Max. static pressure: 10bar

Quick Details

-

Max. Voltage:

-

250

-

Place of Origin:

-

Shanghai, China

-

ering substances: Water/oil:

-

Storage temperature: -29°C~82°C

-

Ambient temperature: -20°C~71°C:

-

Max. static pressure: 10bar

| Model No.: | WFS10 |

| Screw type : | AA , BB , BA |

| Max. pressure difference : | 5 bar |

| Set point repeatability tolerance: | ±1% |

| Set point : |

single fixed |

| Set point parameters | ||

| Model | Set point | Hystersis |

| WFS10002 | 2kPa | 1kPa |

| WFS10003 | 3kPa | 1.5kPa |

| WFS10004 | 4kPa | 1.5kPa |

| WFS10005 | 5kPa | 2kPa |

| WFS10006 | 6kPa | 2kPa |

| WFS10008 | 8kPa | 2.5kPa |

| WFS10010 | 10kPa | 3kPa |

| WFS10012 | 12kPa | 3kPa |

| WFS10013 | 13kPa | 3kPa |

| WFS10014 | 14kPa | 3kPa |

| WFS10016 | 16kPa | 3.5kPa |

| WFS10017 | 17kPa | 4kPa |

| WFS10020 | 20kPa | 4.5kPa |

| WFS10025 | 25kPa | 5kPa |

| WFS10030 | 30kPa | 5kPa |

| WFS10035 | 35kPa | 7kPa |

| WFS10040 | 40kPa | 8kPa |

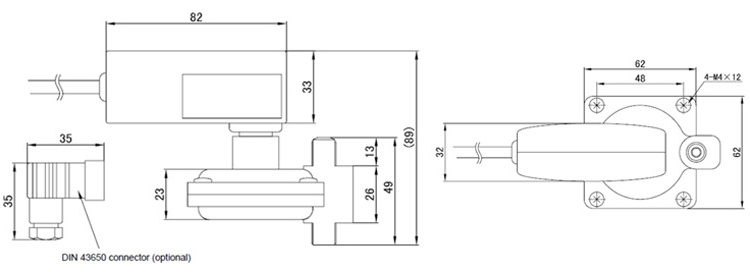

1.the size of the map:

2.Technical Parameters:

1.Shell protection class: IP54

2.Storage temperature: -29~82°C

3.Ambient temperature: -20~71°C

4.Use medium temperature: -20~93°C

5.Working media: Water and air (other media please specify when ordering)

6.High-low pressure side connector: 1/4" SAE

7.Maximum allowable static pressure: 10bar

8.Maximum allowable pressure difference: 5bar

9.Output form: SPDT dry contact output

10.Electrical performance: 5A; 250VAC

11.Cable details: 105°C flame retardant sheath wire 2X0.75mm2

12.Certification: China Quality Certification Center CQC certification

3.Feature:

1.can be customized for customer needs suitable settings

2.M a ke water flow control into a reasonable and accurate age

3.Avoid the user from arbitrarily changing the set value on site , and reduce the failure of the unit due to improper installation and design of the water system .

4.According to the requirements , the differential pressure design value can be converted into flow protection paper for a specific heat exchanger . Ambition

5.C u stomers do not need to adjust , just need to check the traffic flow

Widely used in large and medium-sized air-cooled or water-cooled chillers using plate heat exchangers, tube-type heat exchangers and shell-and-tube heat exchangers for water flow control and water pump and water filter status monitoring.

1.control principle and characteristics:

1.For the measurement of water flow, the pressure drop can be measured at both ends of the valve, orifice plate, etc., and then the pressure drop and flow curve of the valve or orifice plate can be checked to obtain an accurate flow rate, and the flow rate can be obtained by the pressure drop method.Has been widely used in the HVAC water side system and flow measurement instruments.

2.The application of differential pressure switch in HVAC system is mainly controlled according to the resistance and flow curve of HVAC equipment. The water side heat exchanger in HVAC (sleeve type, shell tube type, tube plate type and commonly used plate heat exchanger) , Water filters, valves, and pumps all have their performance curves for pressure drop and flow rate. As long as the pressure difference across the pressure difference switch is compared with the preset value, the flow rate can be accurately controlled.

3. The differential pressure switch is used as the flow control in the HVAC. It has accurate flow control, no additional resistance to the water system, no requirement on the water pipe diameter, and no flow disturbance disturbance. It can replace any type of target flow switch.

4.Compared to the target flow switch, it can avoid false flow caused by pump cavitation, and it also has very accurate reset flow and disconnect flow.

2.Performance comparison of differential pressure flow switch and target flow switch in HVAC water system:

3.application:

Plate and tube heat exchanger water flow control:

1.Plate heat exchangers are small in size and high in heat transfer efficiency. They have been widely used as evaporators or condensers in small and medium-sized chillers. However, the specific structure of plate heat exchangers is destined to enhance its antifreeze protection.

2.One of the main reasons why the plate heat exchanger is frosted is that the flow of water through the plate heat exchanger is less than the rated flow, and the temperature of the refrigerant side of the plate heat exchanger is lower than the freezing point, resulting in ice on the water side of the plate heat exchanger.

3.Extensive tests have shown that when the plate heat exchanger is cooled, the flow rate of the water passing through it is less than 50% of the rated flow. This poses a risk of icing. Therefore, accurate control of the plate heat exchanger with a water flow of not less than 50% of the rated flow has become an antifreeze protection. An important measure.

4.According to the pressure drop and flow curve of the plate change, find the pressure drop of the plate heat exchanger at 50% of the rated water flow. This pressure drop is the lower limit pressure difference of the plate heat exchanger flow protection, and select the appropriate pressure difference according to this value. Switch and install it on the entire machine to test the traffic flow to verify its flow protection value.

5.We recommend that customers in mass production select a fixed set point differential pressure flow switch, and that the pressure differential or flow rate value can be calibrated by ACOL on a special test equipment, which can ensure that your set value is correct and avoid incorrect The effect of the change settings on the device.

When the plate heat exchanger is used as a condenser, proper water flow can ensure that the condensing pressure is controlled within the required range, which is beneficial to the stable operation of the unit.

4.applicable media:

5.wiring diagram:

ACOL (Shanghai) Online Controls Co., Ltd.Since 2002

1.Manufacturer of developing HVAC system control products

2.Set R & D, production, sales, technical services in one of the specialized high-tech company .

3.Aiming at the application of HVAC systems , putting forward a comprehensive system solutions to meet customers demand, developing and providing professional flow control solutions in HVAC system:

(1.)Antifreeze solutions for heat exchanger of Small ,Medium and Large chillers

(2.) Protection solutions of low pressure drop water flow for heat pump systems

(3.) Anti-corrosion water flow protection solutions for Pool heat pumps

(4.) Solutions for Closed expansion water systems

(5.) Control energy-saving solutions for Medium and large central air-conditioning

(6.) Control solutions for Hydraulic module engine room of heat pumps

(7.) The solutions of differential pressure , bypass ,energy-saving for Residential central air conditioning

The solutions of control for Air systems

4. Export to more than 90 countries in Oceania , Europe , Middle East , Southeast Asia , America, Africa