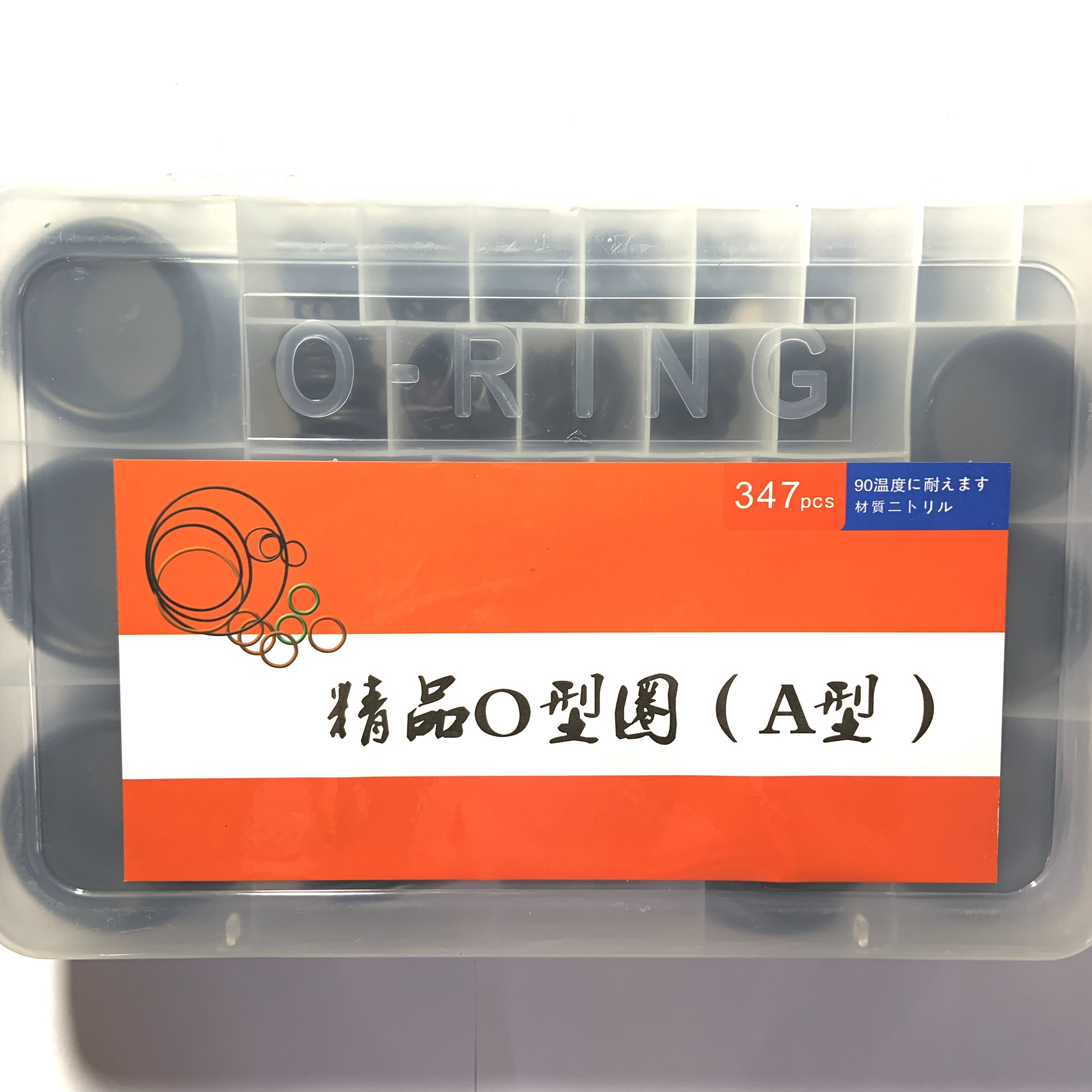

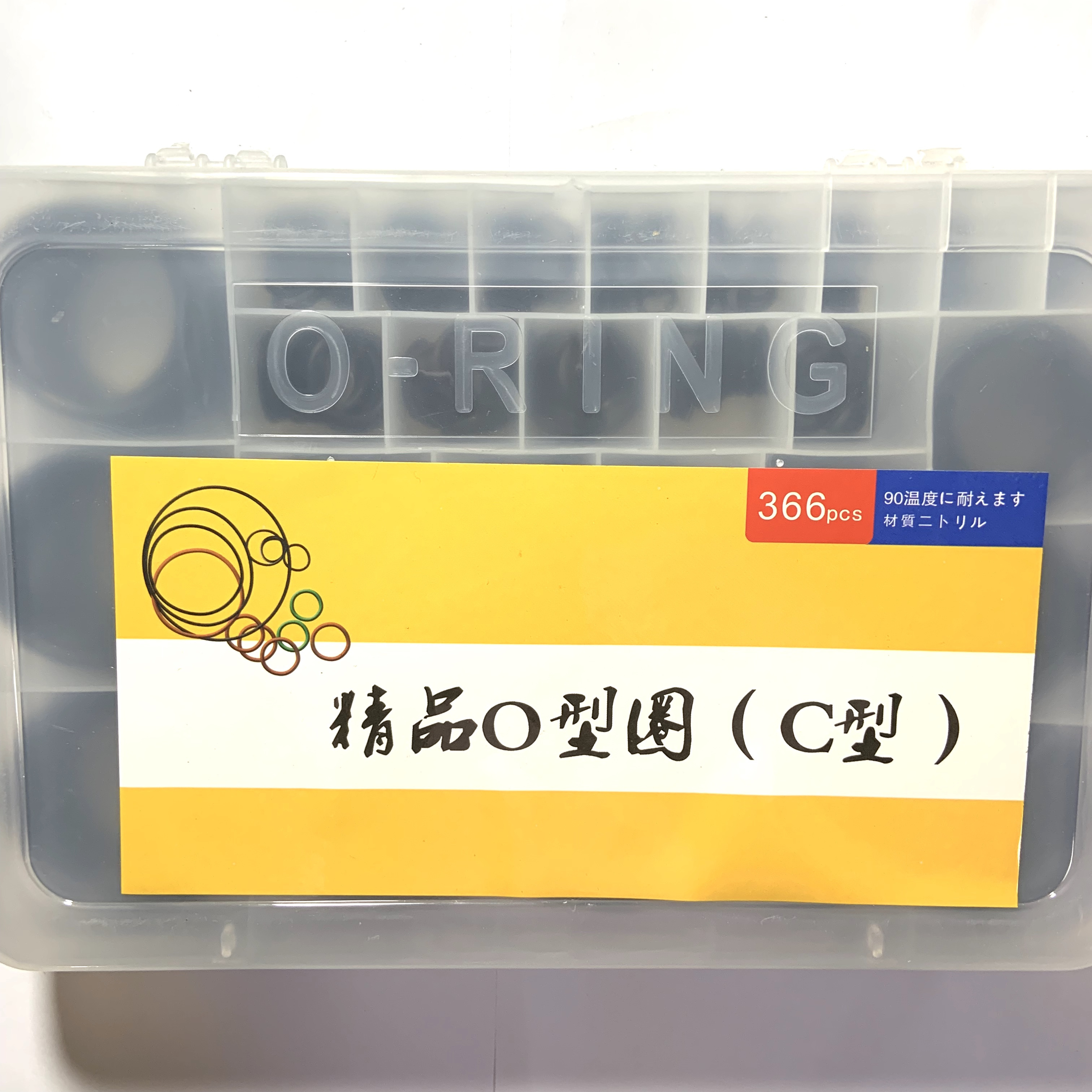

NBR orings(nitrile butadiene rubber)

*Service Temperature

For NBR the service temperature can be designed from -55 °C to 100°C or up to 130 °C depending on differenacrylonitrile content

and formula.

*Application

NBR compounds have excellent resistance to abrasion, non-polar oils and solvent, water and permeation (higher acrylonitrile

content will be better). NBR also can be used in conditions of dilute acids, alkalis and salt solution at low temperatures.