- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V or customizable

-

Power:

-

1.5-4Kw

-

Dimension(L*W*H):

-

2300*1500*1800mm

-

Weight:

-

500 KG

-

Function:

-

shrimp peeling machine for sale

-

Product name:

-

shrimp peeler

-

Application:

-

Shrimp Skin Removing Peeling Machine

-

Name:

-

Prawn peeling machine

-

Usage:

-

shrimp peeling and deveining machine

-

Material:

-

304 Stainless Steel

-

Feature:

-

Electric Automatic

-

Keywords:

-

Stainless Steel Shrimp Peeling Machine

-

Suitable for:

-

Food Processing Plants

-

Advantage:

-

Easy Operation High Efficiency

Quick Details

-

Production Capacity:

-

30-300kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MEST

-

Voltage:

-

220V/380V or customizable

-

Power:

-

1.5-4Kw

-

Dimension(L*W*H):

-

2300*1500*1800mm

-

Weight:

-

500 KG

-

Function:

-

shrimp peeling machine for sale

-

Product name:

-

shrimp peeler

-

Application:

-

Shrimp Skin Removing Peeling Machine

-

Name:

-

Prawn peeling machine

-

Usage:

-

shrimp peeling and deveining machine

-

Material:

-

304 Stainless Steel

-

Feature:

-

Electric Automatic

-

Keywords:

-

Stainless Steel Shrimp Peeling Machine

-

Suitable for:

-

Food Processing Plants

-

Advantage:

-

Easy Operation High Efficiency

Low Price Prawn Processing Cleaning Shrimp Peeling Machine For Sale

Product Description

Machine Introduction:

shrimp peeling machine for sale

can be used as single machine to remove the shrimp shell ,or equip with production line to produce shrimp meat product.

This processing system is composed of several single machines with unique functions, which are mainly used for large quantities of

shrimps

shell-removing processing and deheading.

The equipment has novel concept, compact design, reasonable structure and small floor space, which improves the utilization rate of the production workshop;

High degree of automation, open structure design, easy to clean, easy to operate and maintain.

It is an ideal equipment for smaller/medium/large scale seafood deep process factory and seafood supermarket and any other related shrimp process industry.

Machine Features:

1. The overall material of the product is made of 304 stainless steel, and all parts or materials meet the requirements of hygienic production.

2. Compared with traditional processing methods, it saves a lot of labor, eliminates secondary pollution, greatly improves production efficiency, and is suitable for processing large quantities of shrimps.

3. The system is novel in concept, compact in design, reasonable in structure, and maximizes processing output with the smallest equipment footprint, which improves the utilization rate of the plant.

4. The equipment has a high degree of automation. It is precisely controlled by a touch screen and PLC industrial computer. It has an open structure design, sanitary and easy cleaning, and simple operation and maintenance. It is an ideal equipment for modern large and medium-sized shrimp food processing enterprises.

5. For customers with large output, multiple peeling machines can be used in parallel, and different numbers of peeling machines can be turned on according to the output needs, making the production plan more flexible.

6. During the peeling process of the fully automatic shrimp peeling production line, the number of contact between humans and food is greatly reduced, and hygiene requirements are ensured. The processing time of shrimps is also shortened, which is more conducive to the preservation of shrimps and food safety.

Specification

|

Model

|

MST-BX50

|

MST-BX80

|

MST-BX150

|

MST-BX300

|

|||

|

Capacity

|

30-50Kg/h

|

80kg/h

|

150kg/h

|

300kg/h

|

|||

|

Power

|

1.5Kw

|

2.2Kw

|

3Kw

|

4Kw

|

|||

|

Voltage

|

220/380V

|

220/380V(with frequency conversion)

|

|

|

|||

|

Machine Material

|

304 Stainless Steel

|

|

|

|

|||

|

Machine Size

|

180*140*165cm

|

230*150*180cm

|

230*206*180cm

|

360*226*220cm

|

|||

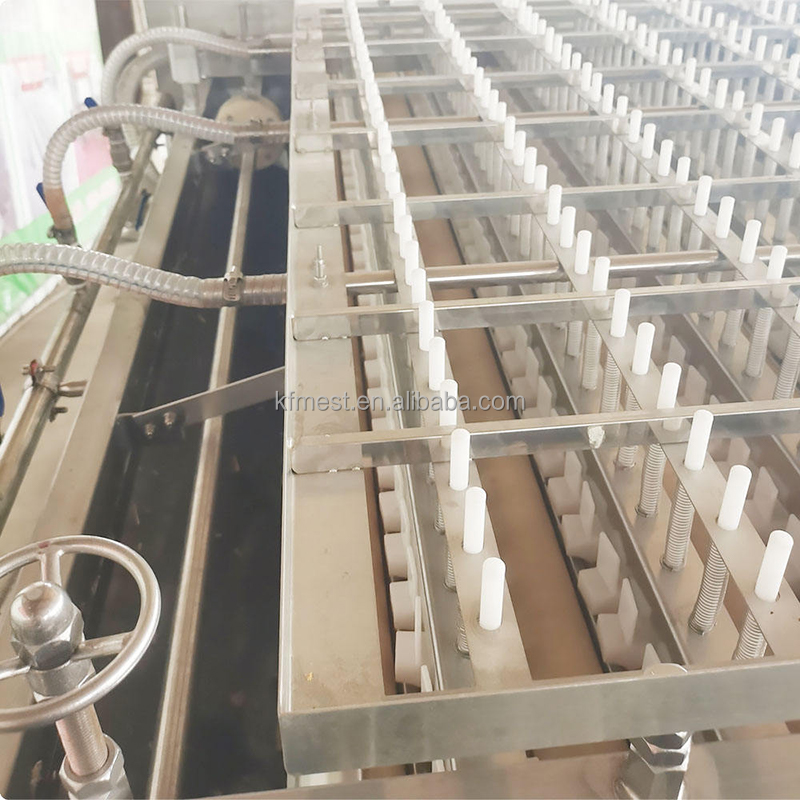

Machine Details

304 stainless steel

The machine is made of 304 stainless

steel ,all parts or materials meet the food safety requirements. durable and not deformed.

steel ,all parts or materials meet the food safety requirements. durable and not deformed.

separation valve

Each of water distribution line is equipped with the separation valve to ensure the uniform water output and improve peeled shrimp integrity.

production output

The production output will depends on the quantity of peeling roller qty. All of peeling production is automatic. With a unique design, the breakage rate of shrimp is low.

PLC Control

PLC touch screen controller system made by Siemens from German. Controlling accuracy; Easy operation and maintenance.

The conveying line is generally fixed. The conveyor has large conveying capacity and long transportation distance, and can also complete several technological operations at the same time during the conveying process.

The automatic shrimp feeding system is mainly used to clean the shrimp and then lift it up for peeling, which saves labor to a certain extent.

Details Images

Part Of Finished Product:

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Certifications

FAQ

Question 1: What are your advantages compared with your competitors?

Answer:With rich industry experience and strict Product Quality Control systems, we provide:

1). Stable and reliable product at reasonable price

2). Good customer service: Fast response to any inquiry or question

3). On-time delivery. Question

2: What are your factory?

Answer: Yes,we are factory with 27 years experience.

Question 3: What are your Payment Terms?

Answer: Payment shall be made by T/T, L/C, or D/P, etc., it varies considerably according to the region that you are in.

Question 4: Can I print my Logo on the machine?

Answer: Yes, sure.

Question 5: Can you customize the machine for me ?

Answer: Yes, we can customize according to customer's requirements.

Question 6: What shall we do if breakdown occurs?

Answer: Please informed us once the breakdown occurs. During warranty period, if breakdown occurs, we shall respond in time after receiving the notification of the buyer. We shall handle failure over the telephone/ fax or arrange relevant personnel to the site according to the buyer’s requirements.

Question 7: Which ports do you usually ship at?

Answer: We can load container at: Qingdao, Shanghai, Ningbo, Tianjin, Guangzhou etc.

Answer: We can load container at: Qingdao, Shanghai, Ningbo, Tianjin, Guangzhou etc.

Question 8. Which kind documents your company can provided?

Answer: After ship depart from China port ,we can get documents from shipping company such as : bill of lading,

insurance documents, packing list, commercial invoice. If you need, we also can apply CO, FORM F, FORM E, CE etc.

insurance documents, packing list, commercial invoice. If you need, we also can apply CO, FORM F, FORM E, CE etc.

Hot Searches