- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

QC-012

-

Thickness:

-

10-300mm

-

Size:

-

800*800mm, customized size

-

Color:

-

black/green/blue/red/orange/other color is available

-

Application:

-

Engineering

-

Feature:

-

high impact

-

Packing:

-

wooden case or pallet

-

Usage:

-

crane foot support pad

-

Certificate:

-

ISO9001:2015

-

Keyword:

-

crane outrigger pad cribbing blocks

-

Advantage:

-

Unbreakable

-

Logo:

-

OEM Logo

-

Customized:

-

Accept OEM Color

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QICHENG

-

Model Number:

-

QC-012

-

Thickness:

-

10-300mm

-

Size:

-

800*800mm, customized size

-

Color:

-

black/green/blue/red/orange/other color is available

-

Application:

-

Engineering

-

Feature:

-

high impact

-

Packing:

-

wooden case or pallet

-

Usage:

-

crane foot support pad

-

Certificate:

-

ISO9001:2015

-

Keyword:

-

crane outrigger pad cribbing blocks

-

Advantage:

-

Unbreakable

-

Logo:

-

OEM Logo

-

Customized:

-

Accept OEM Color

Products Description

Polyethylene outrigger pads for backhoe plastic outrigger pads

UHMW-PE outrigger pads supply a range of lightweight and long-lasting spreader plates that offer stable support when operating cranes work platforms and mobile plant. Made from high quality, heavy duty UHMW PE, our range of outrigger pads offer protection against water, corrosion and splintering – a huge advancement over the more traditional wooden and steel alternatives.

Product Paramenters

|

Project Name

|

Unit

|

Index

|

|

Impulse strength

|

KJ/m2

|

≥140

|

|

Water absorption

|

%

|

≤0.01

|

|

Compressive strength

|

MPa

|

≥30

|

|

Ball-indentation hardness

|

N/mm2

|

≥28

|

|

Flexural strength

|

MPa

|

≥30

|

|

Wear loss

|

G/cm2

|

≤0.0036

|

|

UHMWPE HDPE Crane Outrigger Pads

|

|

|

|

|||

|

Square Outrigger Pad

|

Round/Square Outrigger Pad

|

|

|

|||

|

Common size

|

Loading capacity for crane feed

|

Common size

|

Loading capacity for crane feed

|

|||

|

300*300*40mm

|

3-5 tons

|

300*40mm

|

2-6 tons

|

|||

|

400*400*40mm

|

4-6 tons

|

400*40mm

|

3-7 tons

|

|||

|

400*400*50mm

|

6-10 tons

|

500*40mm

|

4-8 tons

|

|||

|

500*500*40mm

|

10-12 tons

|

500*50mm

|

8-12 tons

|

|||

|

500*500*50mm

|

12-15 tons

|

600*40mm

|

10-14 tons

|

|||

|

500*500*60mm

|

13-17 tons

|

600*50mm

|

12-15 tons

|

|||

|

600*600*40mm

|

15-18 tons

|

600*60mm

|

15-20 tons

|

|||

|

600*600*50mm

|

16-20 tons

|

700*50mm

|

22-30 tons

|

|||

|

600*600*60mm

|

18-25 tons

|

700*60mm

|

25-32 tons

|

|||

|

700*700*60mm

|

25-35 tons

|

700*70mm

|

30-35 tons

|

|||

|

800*800*70mm

|

30-45 tons

|

800*70mm

|

40-50 tons

|

|||

|

1000*1000*80mm

|

50-70 tons

|

1000*80mm

|

45-60 tons

|

|||

|

1200*1200*100mm

|

60-100 tons

|

1200*100mm

|

50-90 tons

|

|||

|

1500*1500*100mm

|

120-180 tons

|

1500*100mm

|

80-150 tons

|

|||

|

Customized size and shape on demand

|

|

|

|

|||

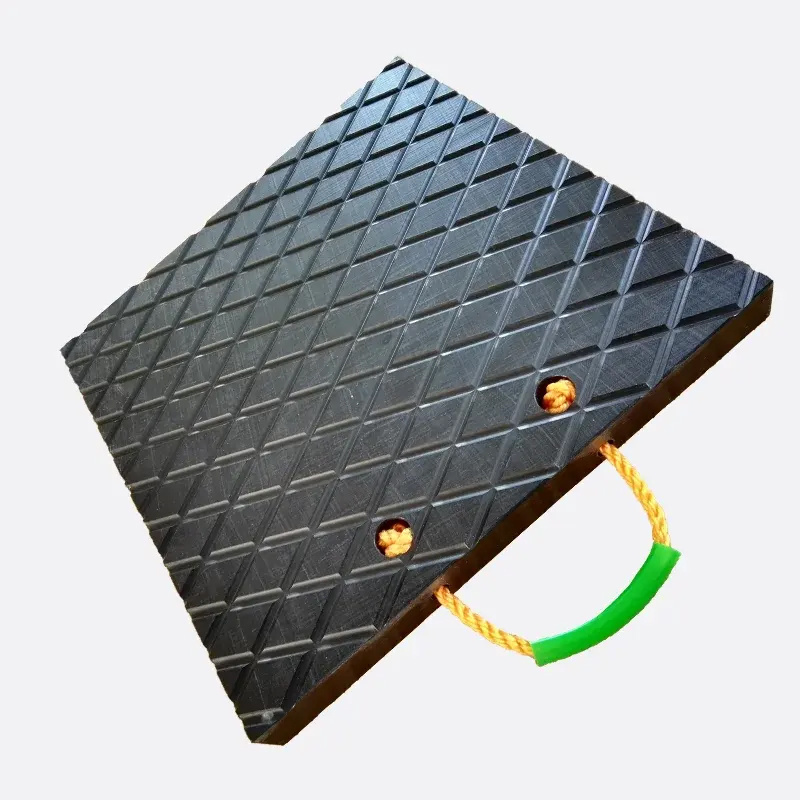

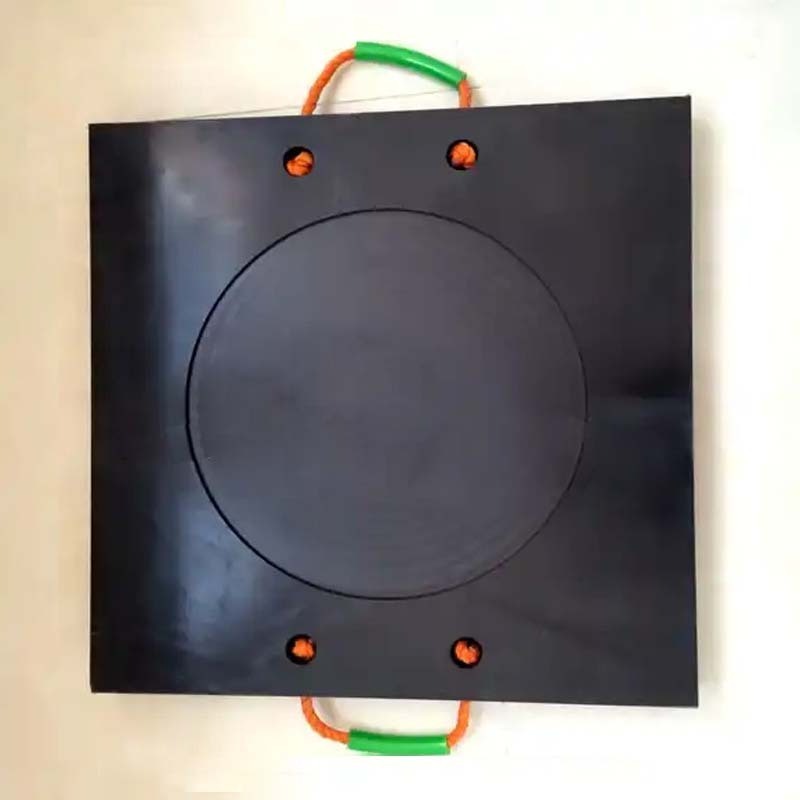

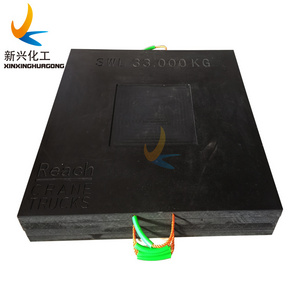

Details Images

Features and Application

Features:

1.Durable synthetic rope handles

2.15% the weight of steel pads

3.Does not rot or splinter

4.Non-slip surface

5.Work in sub-zero temperatures

6.Easy to transport and mount

7.Corrosion chemical wear and moisture resistant

8. Engineered thermoplastic construction

9. Industrial grade safety texturing

10. Rounded edges&corners

11. Personalization stamping, engraving

Applications

・Mobile cranes

・Aerial lifts

・Digger derricks

・Concrete pumpers

・Fire trucks

・Utility trucks

・Military vehicles

・Logging equipment

・Mining equipment

・Concrete protection liner

・Oil and gas equipment

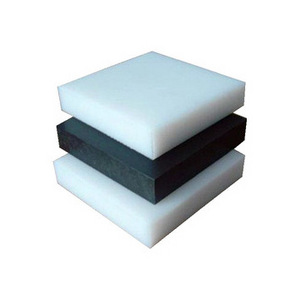

Production Process

Our

UHMWPE Crane Outrigger Pads

use virgin

raw material, it could guarantee that our

final products are with higher quality and long life time.

The mix process for mixing raw material with evenly and high efficiency

.

The forming process -we use high precision forming machine to produce the road mats with higher capacity .

The process of finishing ,we could make different surface according to customer's reqiurements .

The testing process ,each batch of our products will be tested by our standard test room .So we could gurantee that our products are with qualified goods after leaving our factory .

The packing and transported process.

We will make perfect package for our each batch of goods .

Hot Searches