- Product Details

- {{item.text}}

Quick Details

-

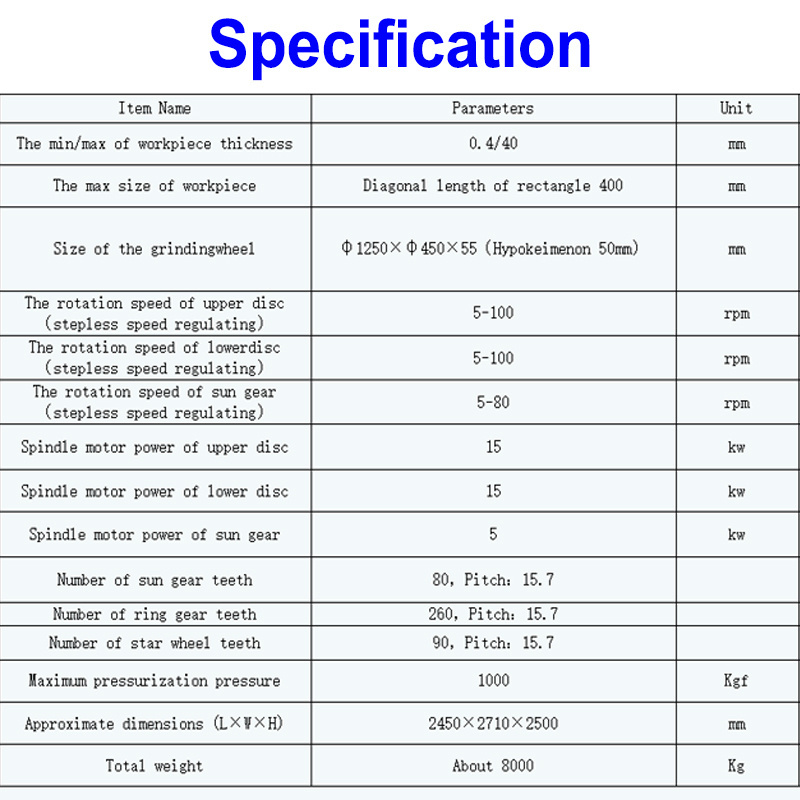

Brand Name:

-

YUHUAN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2700x2400x2600

-

Weight (KG):

-

7900

-

Power (kW):

-

15

-

Usage:

-

High precision flat lapping polishing machine

-

Application:

-

Automotive/seal parts/piston ring/ceramics etcs/

-

Motor power of Sun Gear:

-

15KW

-

Max loading pressure:

-

1000Kgf

-

The Rotation Speed of Upper/Lower Disk:

-

5-100 RPM

-

The Rotation Speed of Sun Gear:

-

5-80 RPM

-

The Max Size of Workpiece:

-

400 mm (Rectangle Diagonal)

-

The Range of Workpiece Thickness:

-

0.4~40 mm

-

Advantage:

-

High Speed/High Precision/Double Surface lapping

-

Keywords:

-

precision lapping machine

Quick Details

-

Wheel Size(mm):

-

1250*450*60

-

Year:

-

2023

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

YUHUAN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2700x2400x2600

-

Weight (KG):

-

7900

-

Power (kW):

-

15

-

Usage:

-

High precision flat lapping polishing machine

-

Application:

-

Automotive/seal parts/piston ring/ceramics etcs/

-

Motor power of Sun Gear:

-

15KW

-

Max loading pressure:

-

1000Kgf

-

The Rotation Speed of Upper/Lower Disk:

-

5-100 RPM

-

The Rotation Speed of Sun Gear:

-

5-80 RPM

-

The Max Size of Workpiece:

-

400 mm (Rectangle Diagonal)

-

The Range of Workpiece Thickness:

-

0.4~40 mm

-

Advantage:

-

High Speed/High Precision/Double Surface lapping

-

Keywords:

-

precision lapping machine

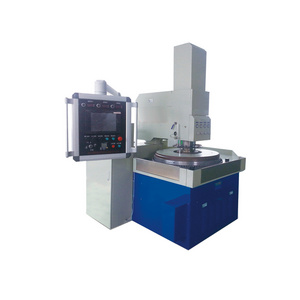

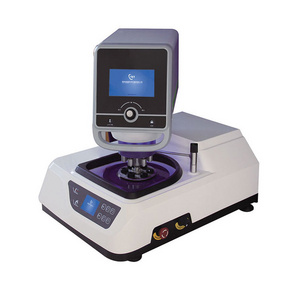

Hot Sale Newest Dual Side Disc Metal CNC Grinder tool high speed double surface precision lapping machine

MAIN FUNCTION

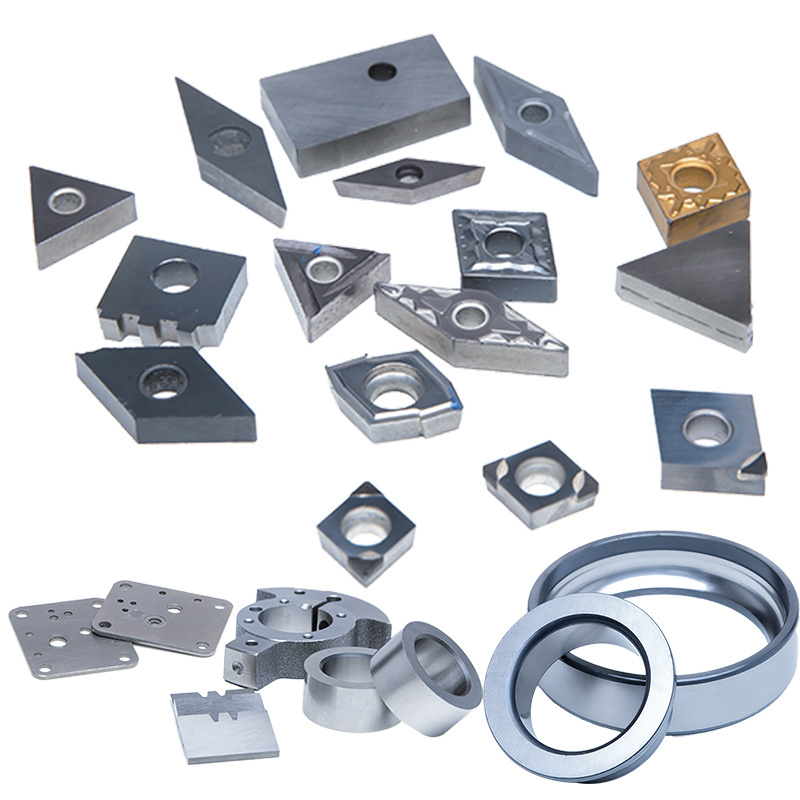

This machine is suitable for efficient and precise double-sided lapping of metals and non-metallic hard and brittle materials such as steel, copper, cemented carbide, and ceramics.

It can be widely used for double-sided precision lapping of hydraulic components, automobile parts, refrigeration compressor parts, oil pump nozzle parts, engine parts, high-precision bearing rollers and rings, seals, carbide blades, ceramic valve cores, magnetic materials and other products.

Flat Lapping Machine Features:

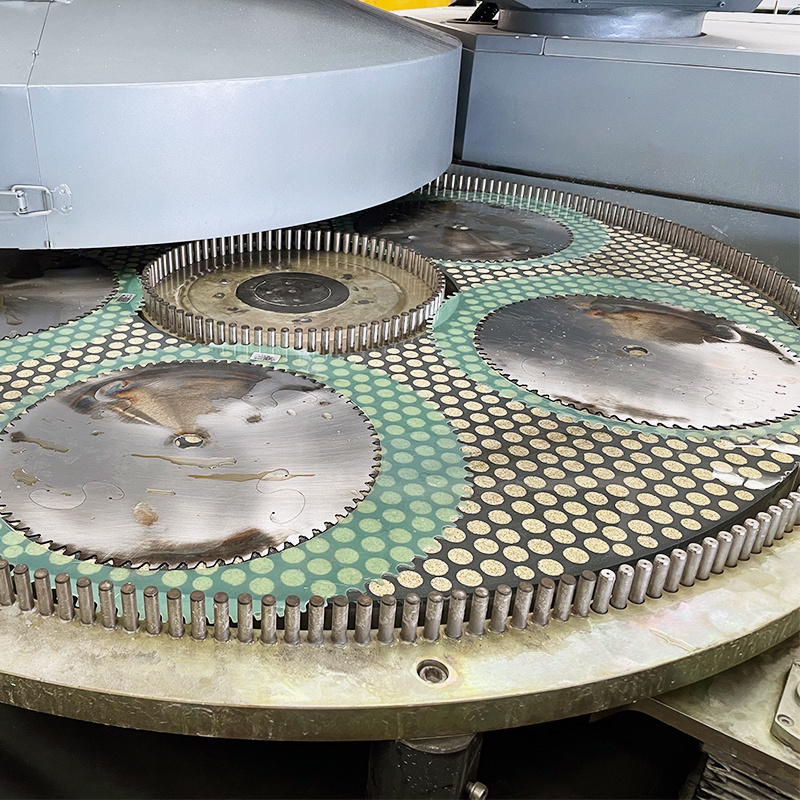

1. This machine is a lapping machine tool based on the motion principle of 4-way planetary gear train;

2. The sun wheel and lower plate of this machine are driven by a direct drive of motor + reducer. It adopts a double-axis sleeve structure. All machines have high rigidity and processing accuracy. Semi-automatic loading and unloading devices are optional. The loading and unloading are easy to replace and easy to adapt. Customer application requirements;

3. An air bag is used to pressurize and lift the upper plate; a reducer is used to directly drive the upper plate to rotate; drum gear transmission ensures flexible loading of the upper plate;

4. Using a cylinder + rack and pinion device, the upper grinding disc can be swung in and out for easy operation and maintenance. Precision electrical proportional valve + pressure sensor are used to ensure the accuracy of the loading pressure of the upper plate. The loading system uses imported measurement sensors to ensure the consistency of processing dimensions, and the processing can realize the interoperability between pressure mode and positioning mode;

|

Item / Model |

Unit |

YH2M84120 |

|

Size of Grinding Wheel |

mm |

Φ1250×φ450×60 |

|

The Max Size of Workpiece |

mm |

370 ( Diagonal length of rectangle ) |

|

The Thickness of Workpiece |

mm |

0.4-40 |

|

The Rotation Speed of Upper/Lower Disc |

rpm |

5-100 |

|

The Rotation Speed of Sun Gear |

rpm |

5-80 |

|

Spindle Motor Power of Upper/Lower Disc |

kw |

15 |

|

Motor Power of Sun Gear |

kw |

15 |

|

Number of starwheel s |

PCS |

5 |

|

Max Pressurization Pressure |

kgf |

1000 |

|

Approximate Dimensions (L*W*H) |

mm |

About 2700×2400×2600 |

|

Total Weight |

kg |

About 7900 |

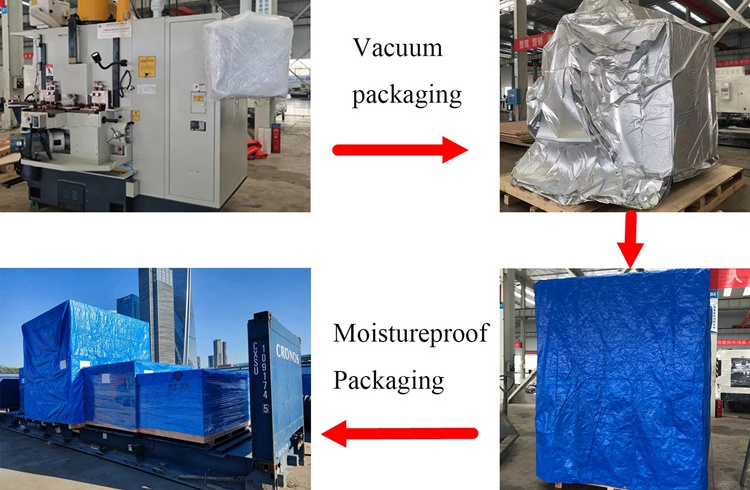

1.Moisture-proof packaging+Wooden Box.

2.Special packing requirements available.