- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Naseiko

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2960*2125*2221

-

Weight (KG):

-

5000

-

Power (kW):

-

30kw

Quick Details

-

Wheel Size(mm):

-

75-150

-

Year:

-

2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Naseiko

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2960*2125*2221

-

Weight (KG):

-

5000

-

Power (kW):

-

30kw

Product Description

Specification

|

item

|

value

|

|

Type

|

Knife grinder

|

|

CNC or Not

|

CNC

|

|

Condition

|

New

|

|

Wheel Size(mm)

|

75-150

|

|

Year

|

2023

|

|

Place of Origin

|

China

|

|

Place of Origin

|

Zhejiang

|

|

Brand Name

|

Naseiko

|

|

Voltage

|

380V

|

|

Dimension(L*W*H)

|

2960*2125*2221

|

|

50Weight (KG)

|

5000

|

|

Power (kW)

|

30kw

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Competitive Price

|

|

Showroom Location

|

Viet Nam, Russia, Turkey

|

|

Applicable Industries

|

Manufacturing Plant, Construction works

|

|

Marketing Type

|

New Product 2023

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Bearing

|

|

OJECT

|

UNIT

|

C818(POWER)

|

|

|

|

Japan servo motor drive (absolute value) stroke (X/Y/Z axis)

|

mm

|

700 / 450 / 300

|

|

|

|

CNC system resolution (X/Y/Z axis)

|

mm

|

0.0001

|

|

|

|

Minimum resolution for

|

mm

|

0.0001

|

|

|

|

programming of handwheel feed (X/Y/Z axis)

|

|

|

|

|

|

THK screw (X/Y/Z axis)

|

-

|

BN-FN32-C3

|

|

|

|

Repositioning accuracy (X/Y/Z axis)

|

mm

|

0.003

|

|

|

|

Guide rail (X/Y/Z axis)

|

mm

|

SRG45-P / SRG35-P / SRG35-P

|

|

|

|

Workpiece rotation axis (A/B axis)

|

-

|

rotation axis

|

|

|

|

DD servo drive (A/B axis)

|

-

|

direct drive

|

|

|

|

Rotary encoder (A/B axis)

|

-

|

RENISHAW, UK

|

|

|

|

Indexing accuracy (A/B axis)

|

-

|

2 arc seconds (0.0005 degrees)

|

|

|

|

Rated speed (A/B axis)

|

rpm

|

300 / 100

|

|

|

|

Maximum revolutions (A/B axis)

|

rpm

|

400 / 150

|

|

|

|

CNC system resolution (A/B axis)

|

degree

|

0.0001

|

|

|

|

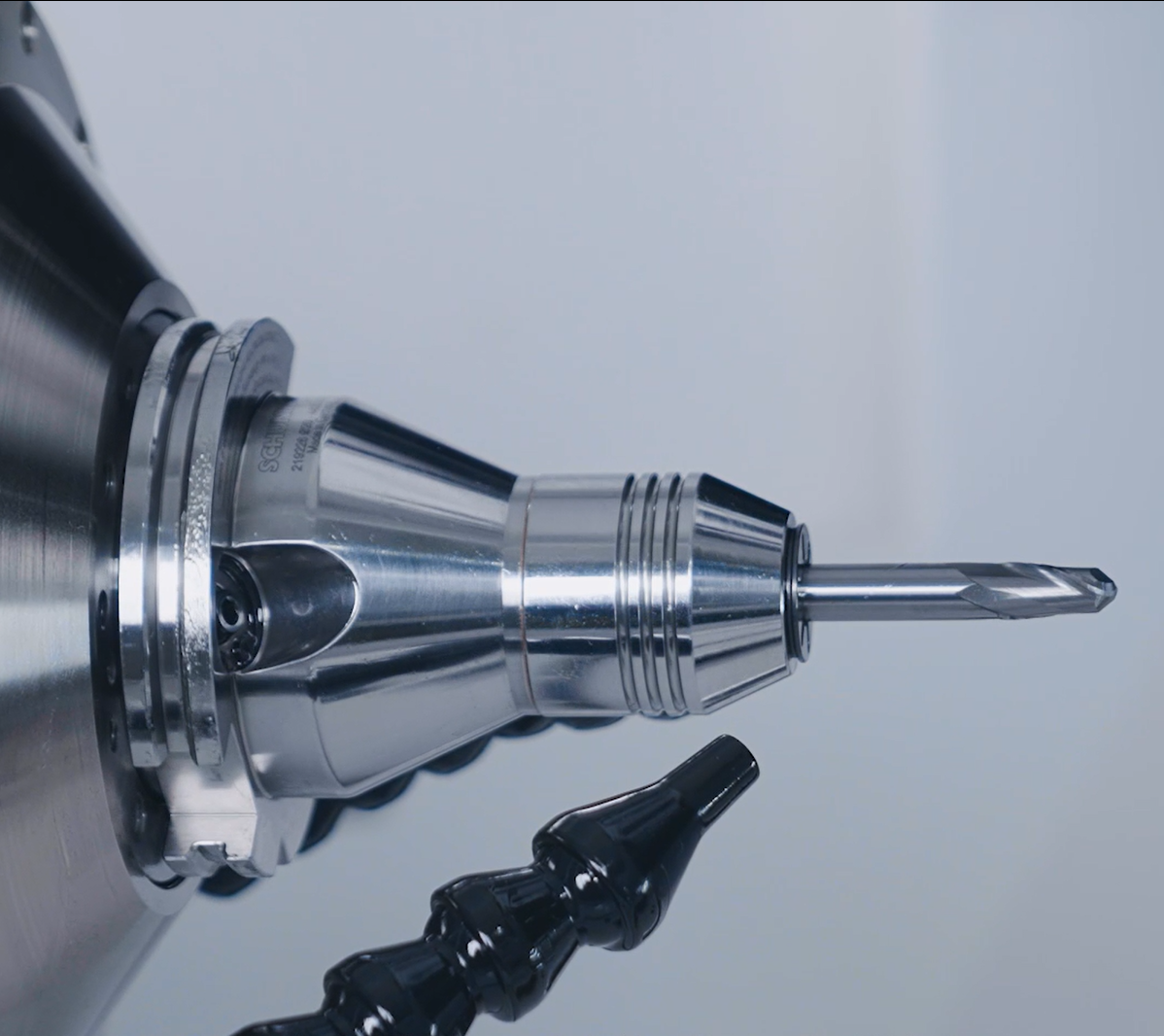

360 degree rotation, indexing head body (A/B axis)

|

-

|

Could be installed with Shaw Berlin W25

|

|

|

|

|

|

collet holder or BT50 knife handle

|

|

|

|

Quick movement (X/Y/Z axis)

|

m/min

|

7.5

|

|

|

|

Minimum diameter for clamping workpiece

|

mm

|

3

|

|

|

|

Maximum diameter for clamping workpiece

|

mm

|

32

|

|

|

|

Maximum length for clamping workpiece

|

mm

|

300

|

|

|

|

Minimum diameter for grinding workpiece

|

mm

|

1

|

|

|

|

Maximum diameter for grinding workpiece

|

mm

|

32

|

|

|

|

Maximum blade length for grinding

|

mm

|

≤180

|

|

|

|

Maximum workpiece weight

|

kg

|

5

|

|

|

|

Linear resolution

|

mm

|

0.0001

|

|

|

|

Linear repeat positioning accuracy

|

mm

|

0.003

|

|

|

|

Rotation resolution

|

mm

|

0.0001

|

|

|

|

Rotation Repetitive Positioning Accuracy

|

degree

|

0.001

|

|

|

|

Spindle power

|

kw

|

22 kw permanent magnet variable frequency motor

|

|

|

|

Grinding wheel diameter

|

mm

|

75-150

|

|

|

|

Grinding wheel spindle speed

|

rpm

|

4000-8000

|

|

|

|

Stepless adjustable

|

-

|

inverter

|

|

|

|

Machine weight

|

kg

|

5000

|

|

|

|

Total power

|

kw

|

≤30kw

|

|

|

|

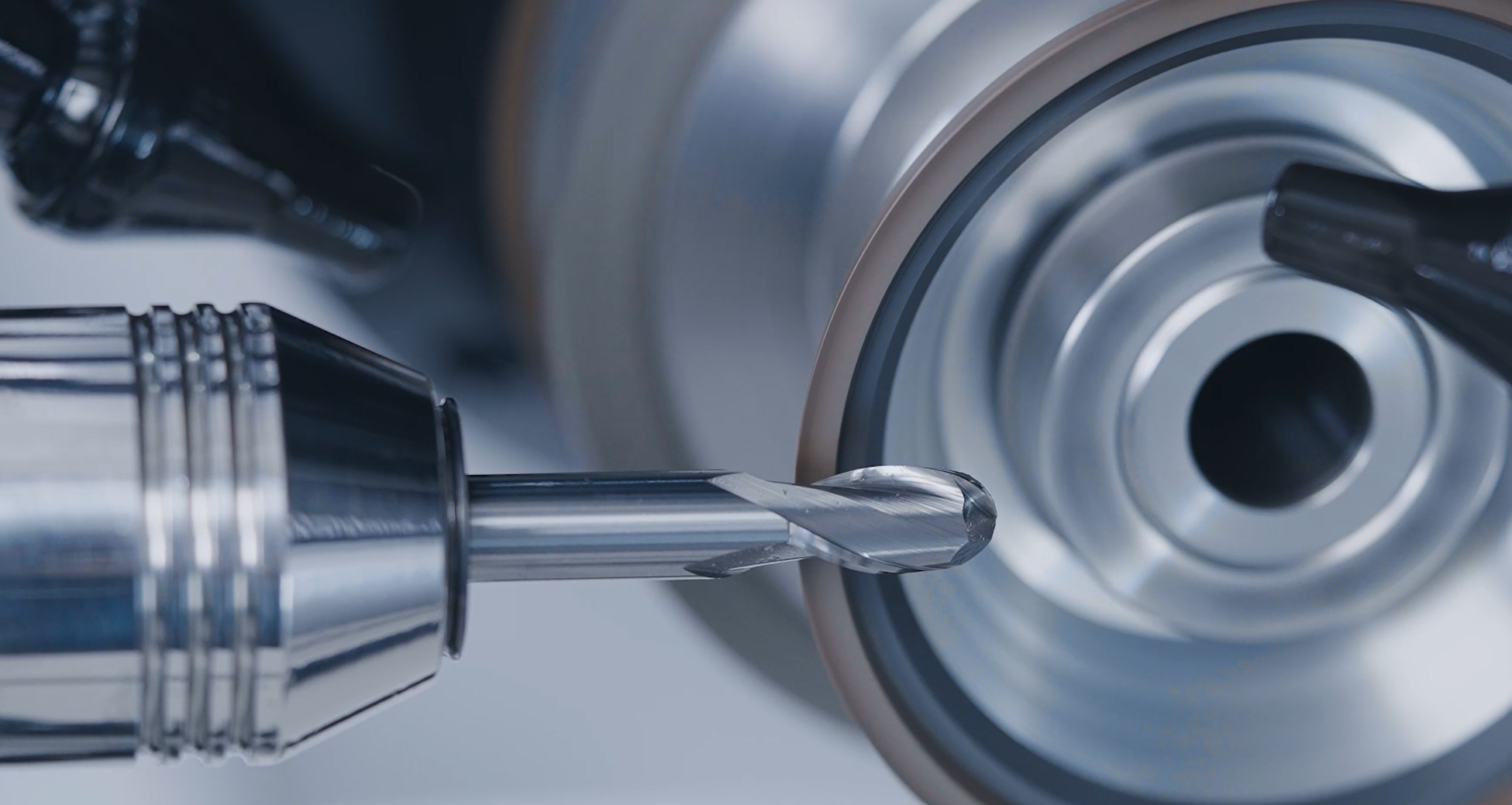

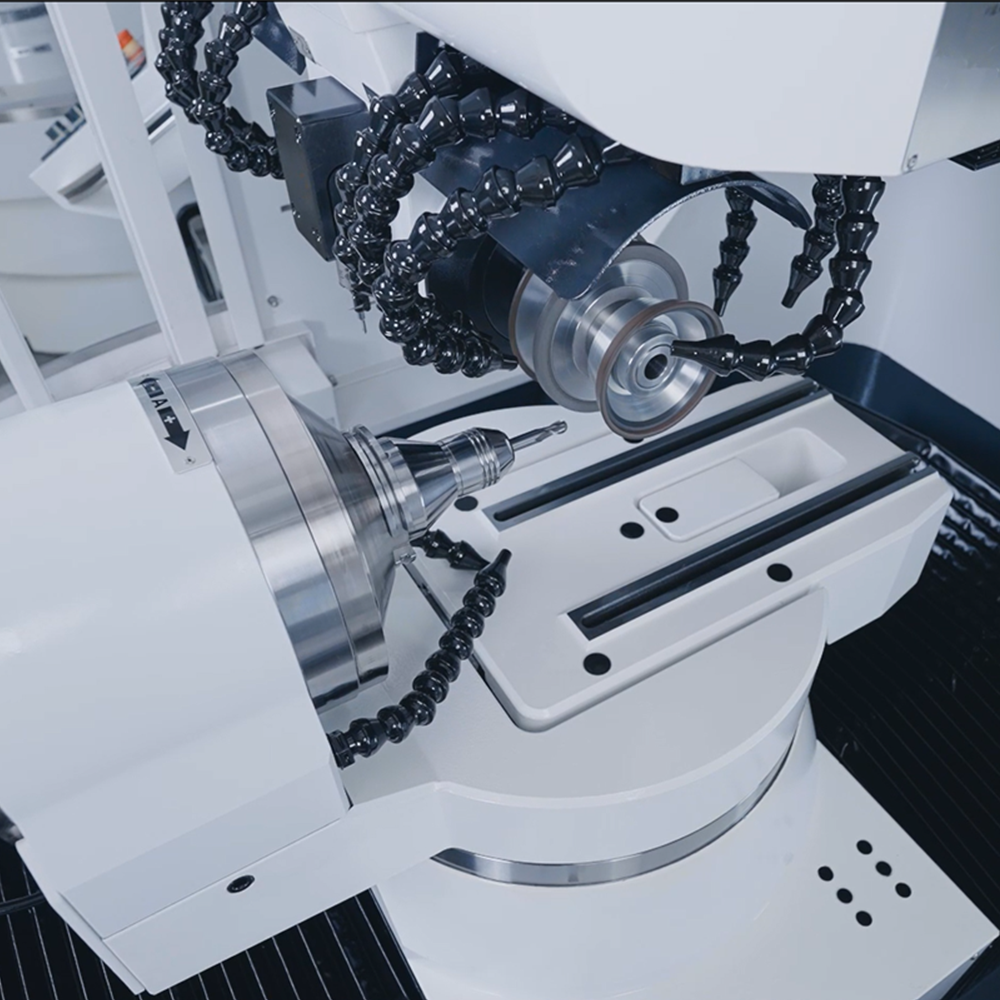

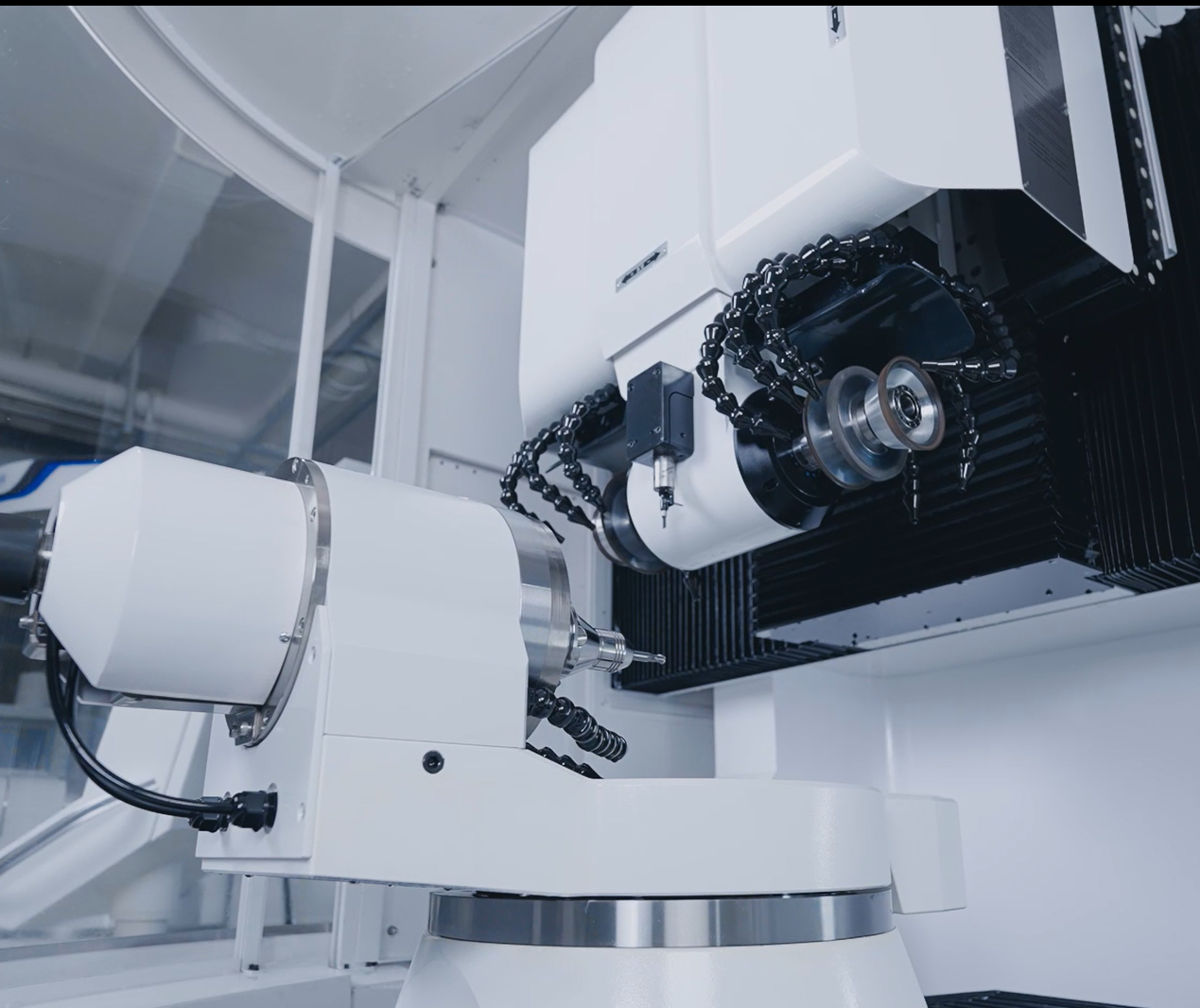

Integral mineral casting bed, Japan servo motor and screw guide rail (heavy-duty roller type) and AB rotating shaft with high

torque DD direct drive motor. |

|

|

|

|

|

|

|

|

|

|

|

The permanent magnet constant torque spindle motor, dual grinding head structure and 360 degrees rotating of B-axis for

non-standard cutting tools procession. |

|

|

|

|

|

|

|

|

|

|

|

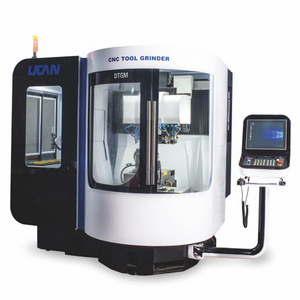

Machines. Designed upon the concept of German 5-axis CNC grinding

|

|

|

|

|

|

|

|

|

|

|

|

Designed by integrating the practical experience and guidance.

|

|

|

|

|

|

|

|

|

|

|

|

CNC System - SYNTEC New Generation, Taiwan

|

|

|

|

|

|

|

|

|

|

|

|

Centralized automatic lubrication station - Shengxiang

|

|

|

|

|

|

|

|

|

|

|

|

Track - THK, Japan

|

|

|

|

|

|

|

|

|

|

|

|

Pneumatic system (solenoid valve, pressure reducing valve, air filter, etc.) - CHELIC, Taiwan

|

|

|

|

|

|

|

|

|

|

|

|

Detection head - Renishaw, UK

|

|

|

|

|

|

|

|

|

|

|

|

Spindle - Taiwan

|

|

|

|

|

|

|

|

|

|

|

|

Circuit accessories - Schneider, France/Omron, Japan

|

|

|

|

|

|

|

|

|

|

|

|

Grating ruler - Heidenham, Germany

|

|

|

|

|

|

|

|

|

|

|

|

Dividing Plate - Shengchang, Taiwan

|

|

|

|

|

Hot Searches