- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

18m*5m*3m

-

Power (kW):

-

122

-

Weight:

-

3-15T

-

Warranty:

-

15 Months

-

Screw L/D Ratio:

-

75/28

-

Screw Speed (rpm):

-

10 - 80 rpm

-

Name:

-

Plastic PET bottle flakes pelletizing line/granulating machine

-

Application:

-

Waste Plastic Recycling

-

Raw material:

-

PET

-

Machine:

-

Plastic pelletizing line

-

Color:

-

Customized

-

Material Process:

-

Waste PET bottle and Film

-

Motor:

-

SIEMENS/WNM

-

Contactor:

-

Schneider/Siemens

-

Inverter:

-

ABB Brand/HOLIP

-

Temperature controller:

-

OMRON/RKC

-

Marketing Type:

-

Ordinary Product

-

Screw diameter (mm):

-

75

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Turkey, Viet Nam, Peru, Mexico, Russia, Spain, Australia, Morocco, Argentina, South Korea, Nigeria

-

Certification:

-

CE ISO9001 TUV SABER

Quick Details

-

Output (kg/h):

-

100 - 1000 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CAMEL

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

18m*5m*3m

-

Power (kW):

-

122

-

Weight:

-

3-15T

-

Warranty:

-

15 Months

-

Screw L/D Ratio:

-

75/28

-

Screw Speed (rpm):

-

10 - 80 rpm

-

Name:

-

Plastic PET bottle flakes pelletizing line/granulating machine

-

Application:

-

Waste Plastic Recycling

-

Raw material:

-

PET

-

Machine:

-

Plastic pelletizing line

-

Color:

-

Customized

-

Material Process:

-

Waste PET bottle and Film

-

Motor:

-

SIEMENS/WNM

-

Contactor:

-

Schneider/Siemens

-

Inverter:

-

ABB Brand/HOLIP

-

Temperature controller:

-

OMRON/RKC

-

Marketing Type:

-

Ordinary Product

-

Screw diameter (mm):

-

75

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Turkey, Viet Nam, Peru, Mexico, Russia, Spain, Australia, Morocco, Argentina, South Korea, Nigeria

-

Certification:

-

CE ISO9001 TUV SABER

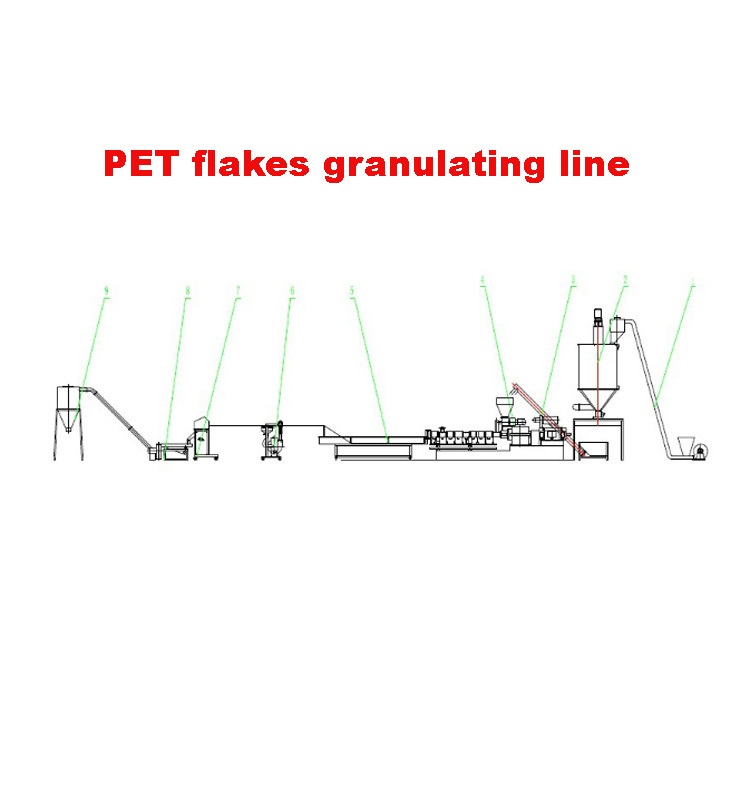

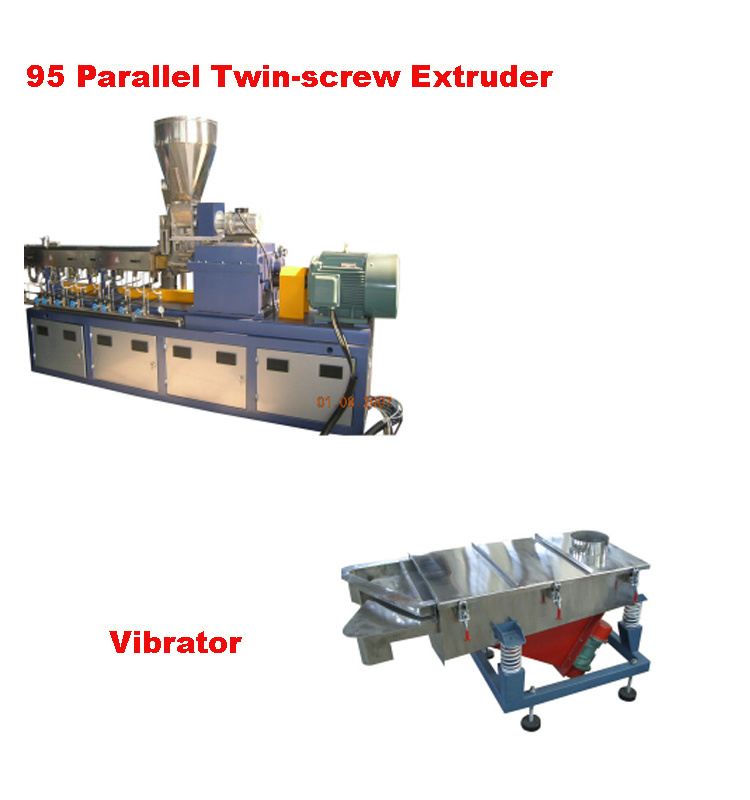

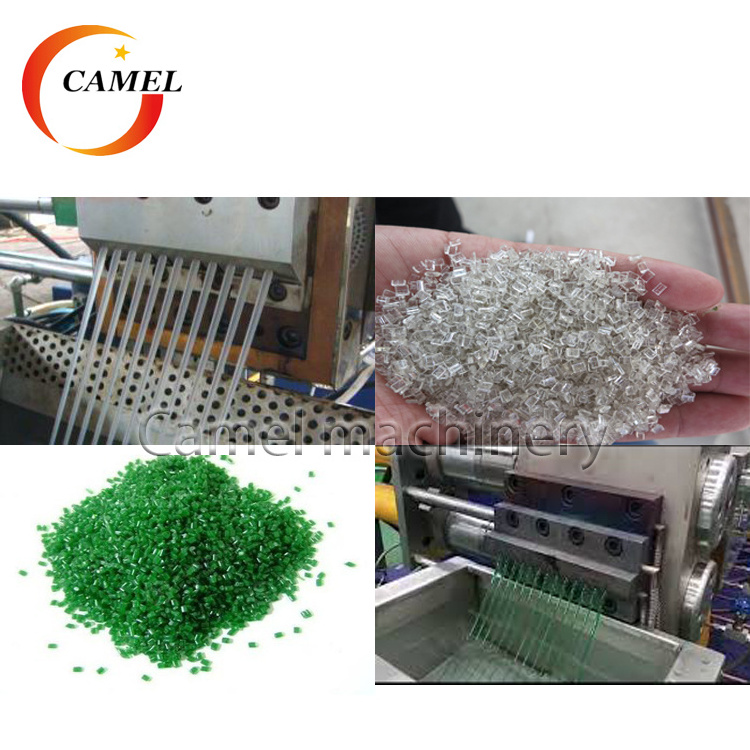

Plastic PET bottle flakes pelletizing line/granulating machine

PET bottle/flakes Granulating/Pelletizing Line/Extruder

1. Screw components designed by computer aids is kneading type, has excellent self-cleaning function,

the new kneading block design effectively avoid the problems of overheating and energy consumption.

2. According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure,

screw array, venting number and location, feeding method, electrical control methods etc. for rational

allocation.

3. Granulation system: water-cooling strand pelletizing , air-cooling die face hot cutting

water ring die face hot cutting , Eccentric water mist hot cutting, water and underwater die face hot cutting and so on.

Technical data:

|

Model |

Screw Diameter (mm) |

Screw L/D |

screw speed N (r/min) |

Main motor power (KW) |

Screw Torque T (N.m) |

Torque Level T/N³ |

Capacity (kg/h) |

|

SHJ20 |

21.7 |

28~40 |

600 |

3/4 |

30 |

4.8 |

3-15 |

|

SHJ35 |

35.5 |

28~56 |

500 |

11 / 15 |

115 |

4.2 |

20-70 |

|

SHJ50 |

50.5 |

28~56 |

500 |

45 / 55 / 75 |

425 |

5.1 |

80-150 |

|

SHJ52B |

51.4 |

28~56 |

400/500/600/800 |

45 / 55 / 75 |

425 |

5.1 |

120-280 |

|

SHJ65 |

62.4 |

28~56 |

500 / 600 |

55 / 75 / 90 |

675 |

4.8 |

150- 25 0 |

|

SHJ65B |

62.4 |

28~56 |

400/500/600/800 |

90/110 |

675 |

4.8 |

200-500 |

|

SHJ75 |

71 |

28~56 |

500 / 600 |

90 /110 /132 |

1005 |

4.6 |

25 0- 3 50 |

|

SHJ75B |

71 |

28~56 |

400/500/600/800 |

110 /132/180 |

1005 |

4.6 |

300-700 |

|

SHJ95 |

93 |

28~56 |

400 / 500 |

250 / 315 |

2815 |

5.9 |

600-1000 |