- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.4-0.6mm

-

Place of Origin:

-

China

-

Weight:

-

3500 kg

-

Feeding width:

-

454mm

-

Marketing Type:

-

New Product 2024

-

Name:

-

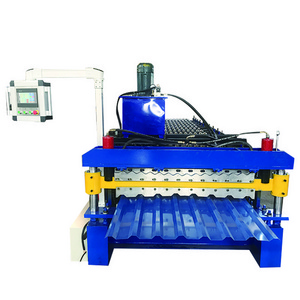

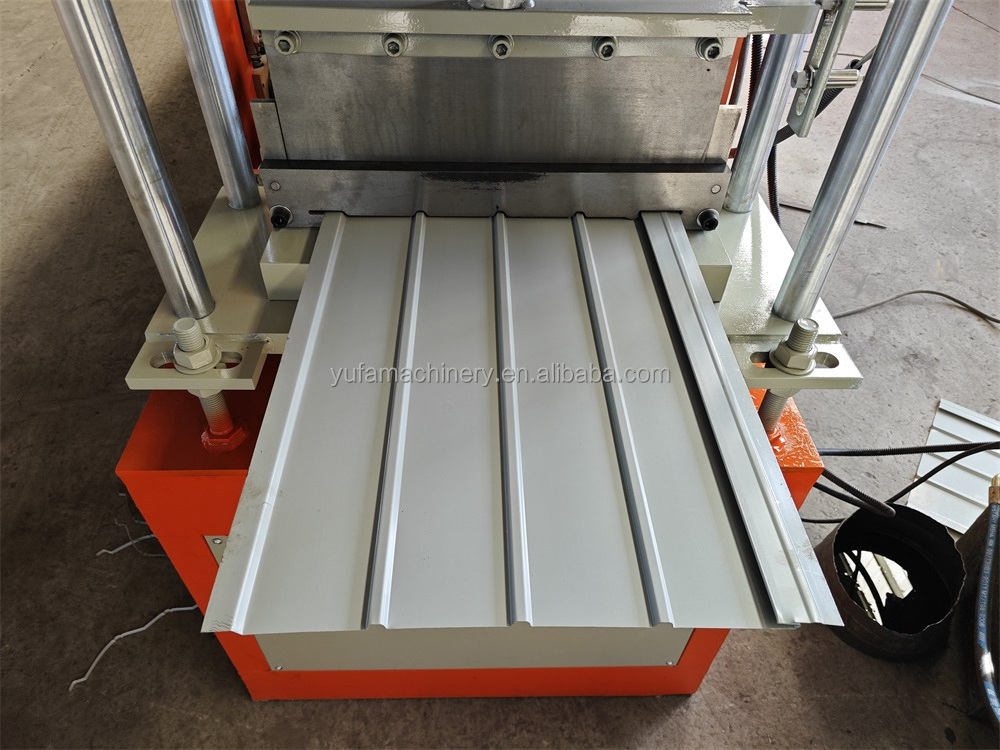

2024 year Malaysia customized metal siding panel roll forming machine

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Raw material:

-

PPGI

-

Main frame:

-

Steel Plate Welded

-

Control system:

-

Taiwan Delta

-

Roller material:

-

High Grade 45# Steel

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Thickness:

-

0.4-0.6mm

-

Color:

-

Customised

-

Cutting type:

-

Automatic Hydraulic Cutting

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.4-0.6mm

-

Place of Origin:

-

China

-

Weight:

-

3500 kg

-

Feeding width:

-

454mm

-

Marketing Type:

-

New Product 2024

-

Name:

-

2024 year Malaysia customized metal siding panel roll forming machine

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Raw material:

-

PPGI

-

Main frame:

-

Steel Plate Welded

-

Control system:

-

Taiwan Delta

-

Roller material:

-

High Grade 45# Steel

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Thickness:

-

0.4-0.6mm

-

Color:

-

Customised

-

Cutting type:

-

Automatic Hydraulic Cutting

| Roll forming machine name | 2024 year Malaysia customized metal siding panel roll forming machine |

| Brand of plc | Delta |

| Material of rollers | High grade 45# steel with 0.05mm chormed |

| Material of shafts | Soild high grade 45# steel |

| Diameter of shaft | 60mm |

| Material of blade | Cr12 ateel |

| Transmission | Chain |

| Motor voltage | 4150V 50Hz 3P or customized |

| Motor kw | 4kw |

| Cutter system | Automatic Hydraulic cutter system |

| Hydraulic pump kw | 3 kw |

| Machine base frame | Steel channel welding with four supported legs |

| Raw material | ppgi |

| Thickness of raw material | 0.4-0.6mm |

Ted will take all pictures for every steps. We will collect the details in record. When you need any help about roll forming machine, we can send you detailed picture. So it is easy for you to understand.

Client is first and Service is first

Before ordering :

We can help to analyze the roof tile in your market. Which one is popular and which one will be popular.

Then your product is hot sale roof tile .

We can confirm all details of the roof tile roll forming machine together, including the drawing, thickness of material, hardness of the steel coil, the input width of the steel coil, capacity of the roll forming machine.

We can help you to find the real manufacturer of steel coil manufacturer. Say bye to Trade company. So you can order the material coil with lowest price.

During production :

We can send the pictures to show you the schedule of your roll forming machines.

We will show you my blogger account for you to learn knowledge of roll forming machine if you would like

We will ask you what color of the roll forming machine body. Produce the machine under your suggestion

After-sale service :

We supply one year guarantee for the machine. The parts of the roll forming machine are free to send you and you only need to pay the cost of freight. And you can aslo solve it if you ordered more parts for your rol forming machine .

We supply all life tech support of our roll forming machines, Any questions, you can contact me by whatsapp.( I suggest that whatsapp or wechat is good. Because i can get your words timely) Important thing, you can write mail to me.

We have rich experiences in loading job. Protect the machine during the shipment.

1 . Q: Are you a manufacturer?

A:Yes, we are manufacture with four branch factories.

2. Q: How should I do if I would like to order my machine

A: Send me your design drawing if you have.

Or tell me your design idea. I arrange my engineer to drawing it for your confirmation.

3. Q: What details of the machine you should get from me.

A: I will confirm all details with you, such as the voltage in your city.

4. Q: I am new in this field. How could i understand the machine very well

A: Why not contact me whatsapp: 0086 16632710788 . I promise you that you will be professional after you get from me. It is true thing.

5. Q: I receive a lot of quotations, they are big range, How could i choose?

A: I have many easy ways to solve it. Fox example, I can teach you how to find the Traders out. Just contact me. It is free for contacting with me.

6. Q: Can you give me one suggestion for ordering the machine.

A: No problem. Do not trust your eyes when you see beautiful pictures of machines or factories. More when you contact.

7. Q: I have not whatsapp and skype, how could I contact with you

A: Send me one inquiry in the end of this page. Leave your contact information for me. I will contact you. It is free.

8. Q: What do you think what is the most important for roll forming machine

A: Drawing ! Drawing ! Drawing

9. Q: Can you use other brand of spare parts for me if i want.

A: No problem if you want to pay the money.