- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

11

-

Weight (KG):

-

2500

-

Application:

-

Deburring, Smoothing, Polishing...

-

Advantage:

-

High Productivity

-

Voltage:

-

Country Voltage

-

Operation:

-

Easy-to-use

-

Certification:

-

CE ISO9001

-

MOQ:

-

1 Set

-

After-sales Service Provided:

-

Free Spare Parts, Online Support, Video Technical Support.

-

After Warranty Service:

-

Spare Parts, Online Support, Video Technical Support.

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Lucky Bridge

-

Marketing Type:

-

Hot Product 2022

-

Power (kW):

-

11

-

Weight (KG):

-

2500

-

Application:

-

Deburring, Smoothing, Polishing...

-

Advantage:

-

High Productivity

-

Voltage:

-

Country Voltage

-

Operation:

-

Easy-to-use

-

Certification:

-

CE ISO9001

-

MOQ:

-

1 Set

-

After-sales Service Provided:

-

Free Spare Parts, Online Support, Video Technical Support.

-

After Warranty Service:

-

Spare Parts, Online Support, Video Technical Support.

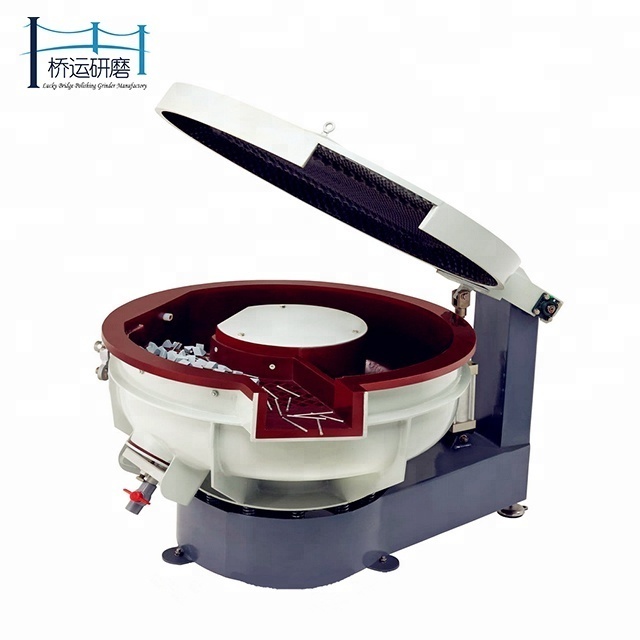

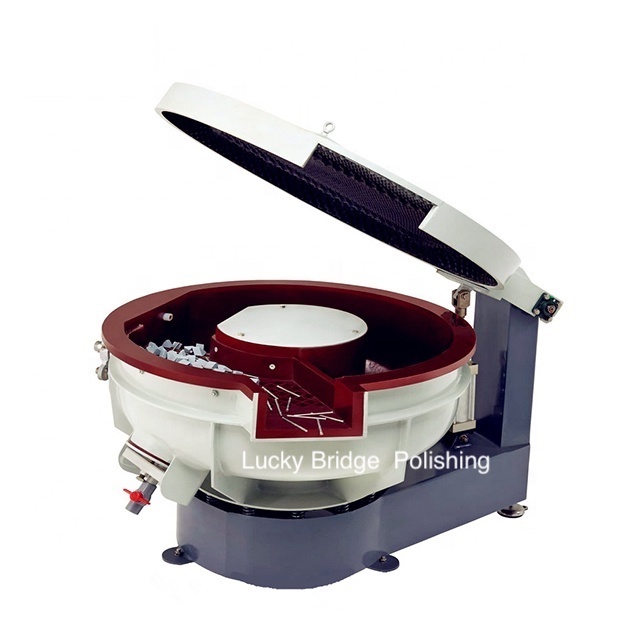

The vibratory machine key application are processing parts made of metals, non-ferrous metals and non-metals. Besides, engineers use the process for burr and rust removal, metal parts edge rounding and mirror polishing. In addition, this process is popular especially for polishing process of parts with complicate surface geometry and concave surface.

After processing, there is no damage on parts surface and no affect on parts dimensions. Also, surface roughness of parts can improve 1-2 degree. Vibratory machine is suitable to finish small to medium size parts in a larger batch quantity.

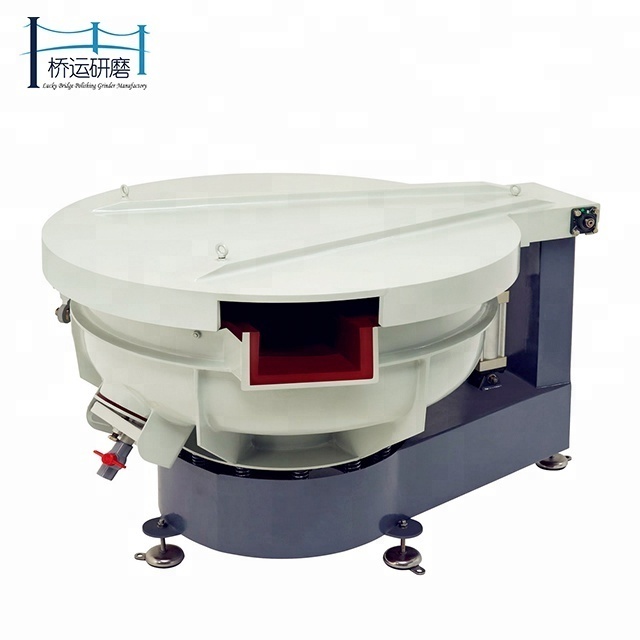

√ Manually insert-able separation gate or pneumatically activated separation flap option.

√ Convenient operation and reduced labor costs.

√ Adjustable imbalance weights allow different finishing intensities.

√ Wear-resistant lining made from high quality PU.

√ Media unload plug with integrated effluent drain.

|

Model

|

Capacity

(L/Cu.Ft)

|

External Diameter Max

(mm/inch)

|

Process Bowl Width

(mm/inch)

|

Process Bowl Depth

(mm/inch)

|

Machine Height

(mm/inch)

|

Motor Power & Speed

(kW & rpm)

|

Weight

(kg/lbs)

|

|

SWS 150

|

150/

5.3

|

1100/

43.3

|

220/

8.7

|

310/

12.2

|

780/

30.7

|

1.5/2.2 & 1450

|

300/

661.4

|

|

SWS 200

|

200/

7.1

|

1330/

52.4

|

265/

10.4

|

370/

14.6

|

850/

33.5

|

3.0 & 1450

|

460/

1014.1

|

|

SWS 300

|

300/

10.6

|

1400/

55.1

|

300/

11.8

|

400/

15.7

|

960/

37.8

|

3.7/5.0 & 1450

|

560/

1234.6

|

|

SWS 400

|

400/

14.1

|

1500/

59.1

|

350/

13.8

|

430/

16.9

|

990/

39.0

|

3.7/5.0

& 1450

|

650/

1433.0

|

|

SWS 600

|

600/

21.2

|

1950/76.8

|

400/15.7

|

480/18.9

|

1250/49.2

|

5.5/7.5 & 1450

|

1400/

3086.5

|

|

SWS 1200

|

1200/

42.4

|

2200/

86.6

|

550/

21.7

|

560/

22.0

|

1600/

63.0

|

11.0

& 1450

|

2500/

5511.6

|

OPTIONS can be provided

★★★Speed Control Box (Variable Speed Motor, Emergency, Other Buttons)

★★Sound Proof Cover (150L/200L: Manual ≥300L: Pneumatic )

★★Separator Lever (Standard; Choose: Manual / Auto Functionality)

★Automatic Liquid System (Compound, Water)

Can be customized to suit user applications, ★ is popularity options.

OPTIONS pictures

Auto Liquid System

Sound Proof Cover

Pneumatic Separator

Control Box

Manual Separator

Pneumatic Type

Lucky Bridge Company has always been committed to providing customers with high-quality surface treatment products and advanced surface treatment processes. Over 25 years’ surface treatment experience in the area, we have the lowest cost and best technology to our customers. We are proud of our professional advice, quality machine, fast technical delivery, and trusted after- sales service.

[A1] Laser Cutting → Welding → Shot Blasting → PU Casting → Painting → Testing. We use high-quality raw materials and control every production step strictly. After production, we will test all parts, especially the running of motor and PU quality. We promise that the machine has excellent performance. The warranty period of our machine is two years, in case of non-human damage.

[Q2] How Do You Control the Quality of Consumables?

[A2] Starting with the mixing ratio of raw materials, until the sorting of impurities. We have mastered the points that need attention in each step. The low loss, high grinding capacity and high polishing ability of media are our advantages.

[Q3] How Long is Your Lead Time?

[A3] We will arrange shipment within 12 days after payment. 15 days ready to leave at Shanghai port or Ningbo port.

[Q4] Can You Provide Sample Finishing Process?

[A4] Yes, we provide FREE sample finishing process. Lucky Bridge does not charge any service fee for sample trial. Please contact us!

[Q5] Can You Provide Cleaning System?

[A5] Yes, we also make the cleaning system, it is also named waste water treatment.

[Q6] Can You OEM the Tumbling Media?

[A6] Yes, we offer OEM solutions for tumbling media. You just send us the media sample, we will make a testing report then we talk it.

[Q7] Can I Reduce the Noise of Vibratory Finishing Machine?

[A7] Yes, we can make a soundproof cover to reduce the noise.

[Q8] Is Easy to Operate Your Mass Finishing Machine?

[A8] Yes, the machine is very easy to operate, and we also guide you how to use at first time.

[Q9] What is Your Mass Finishing Machine Finishing Process Method?

[A9] Deburring, Polishing, Radiusing, Degreasing, Cleaning, Smoothing, Fine Polishing, Mirror Polishing, Super Finishing, Isotropic Finishing, Ball Burnishing, Derusting, Descaling, Pickling, etc.

[Q10] What is Your Packaging Way?

[A10] About machine, strong plywood for only one set. About media, 25kgs per woven bag, 1000kgs per pallet. About compound, 50kgs or 25kgs per plastic barrel.

[Q11] What are Your Price Terms?

[A11] FOB, CFR, CIF, EXW, DDU, DAP Price mainly. If you need delivered price (DDU, DAP), you may have to wait 1-2 days.

[Q12] What is the Nearest Port?

[A12] Shanghai port, Ningbo port.

[Q13] What is Your Payment Method?

[A13] T/T usually, we also accept Paypal. We provide all customers with Trade Assurance Order. “PQS” Protection. (Payment Protection, Quality Protection, Shipping Protection)

[Q14] Which Certificates do You Have?

[A14] ISO9001:2015, CE, SGS, Safe Transportation Report, etc.