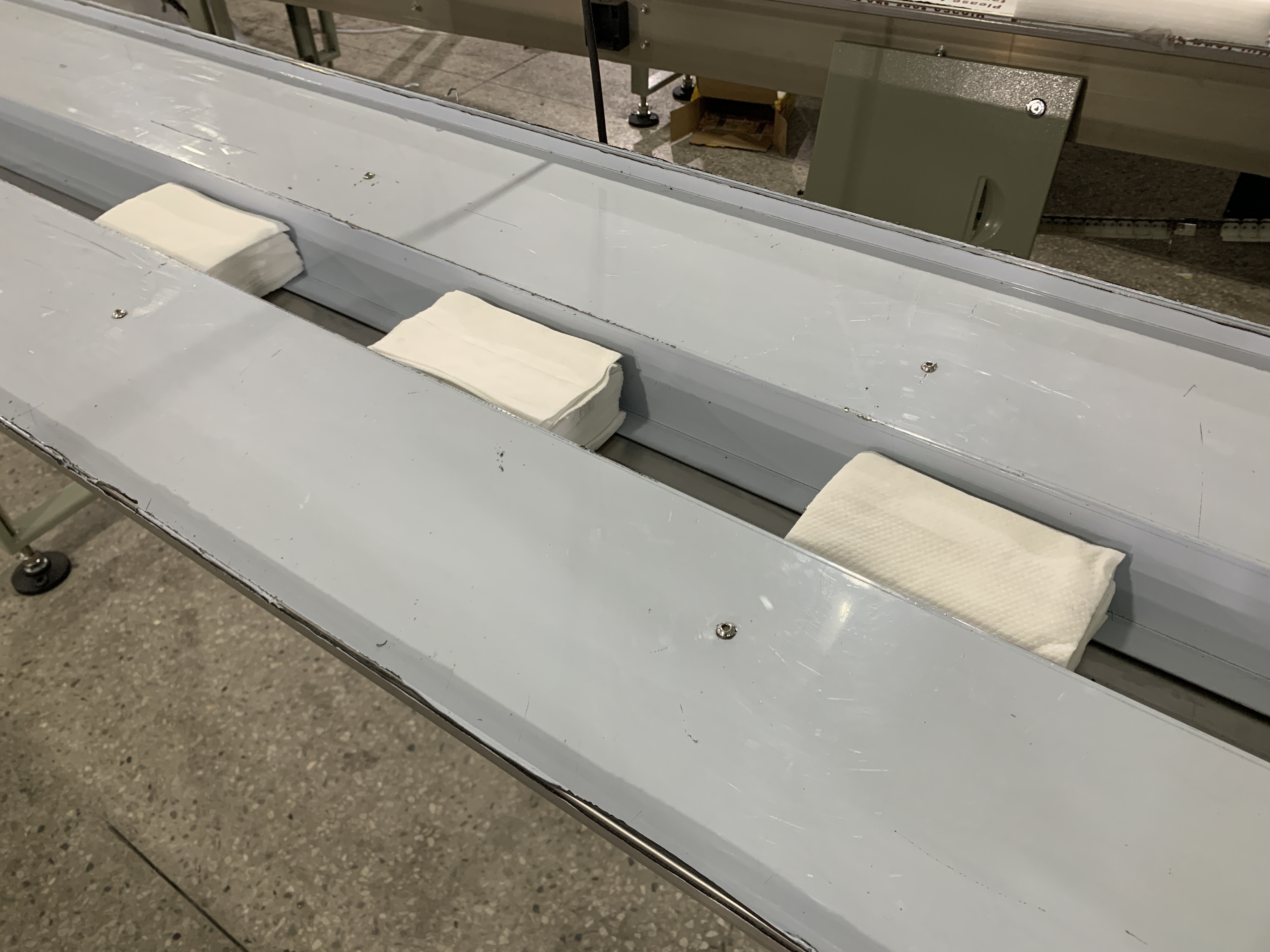

Name: External Film Placement

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

368

-

Voltage:

-

220V,50/60HZ, 2.4KVA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Taichuan

-

Dimension(L*W*H):

-

L3770*W670*H1450mm

-

Product name:

-

HorizontalPacking machine

-

Bag type:

-

Pillow Bag

-

Bag length:

-

65-190mm/120-280mm/90-220mm/150-330mm

-

Bag width:

-

25-42mm/55-75mm/55-110mm

-

Power Supply:

-

220V 50Hz-60Hz,2.4KVA

-

Packing Film Material:

-

OPP.PE.PVC.OPP

-

Speed:

-

40-230bags/min

-

Product Hight:

-

Max.35/50mm

-

Control system:

-

PLC+LCD Screen

Quick Details

-

Function:

-

FILLING, Wrapping, Sealing

-

Packaging Type:

-

Bags, Film

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

368

-

Voltage:

-

220V,50/60HZ, 2.4KVA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Taichuan

-

Dimension(L*W*H):

-

L3770*W670*H1450mm

-

Product name:

-

HorizontalPacking machine

-

Bag type:

-

Pillow Bag

-

Bag length:

-

65-190mm/120-280mm/90-220mm/150-330mm

-

Bag width:

-

25-42mm/55-75mm/55-110mm

-

Power Supply:

-

220V 50Hz-60Hz,2.4KVA

-

Packing Film Material:

-

OPP.PE.PVC.OPP

-

Speed:

-

40-230bags/min

-

Product Hight:

-

Max.35/50mm

-

Control system:

-

PLC+LCD Screen

|

Model

|

TCZB-250B/D

|

|

Film Width

|

Max.250mm

|

|

Film Width (Bag Former)

|

80-114mm/114-180mm/140-250mm

|

|

Bag Width

|

25-42mm/55-75mm/55-110mm

|

|

Bag length

|

65-190mm/120-280mm/90-220mm/150-330mm

|

|

Product High

|

Max.35/50mm

|

|

Packing Speed

|

40-230 bags/min

|

|

Packaging Film Materials

|

Laminate plastic Film,such as OPP/CPP/OPP/CE/MST/PE etc.

|

|

Power

|

220V,50/60Hz,2.4KW

|

|

Film Roll Diameter

|

Max.320mm

|

The difference between up and down film

According to the position of the roll film,the flow packing machine can be divided into two types : up film packing machine and down film packing machine

Up film packing machine

is

Suitable for packing regular objects such as biscuit, bread, instant noodle, moon cakes, industrial parts, paper box or trays.

Down film packing machine

is suitable for

Packaging soft, strip and irregular objects like towels, tissues, noodles, egg rolls, sausages, fish, ice lollies, soft.candies, fresh fruits, etc

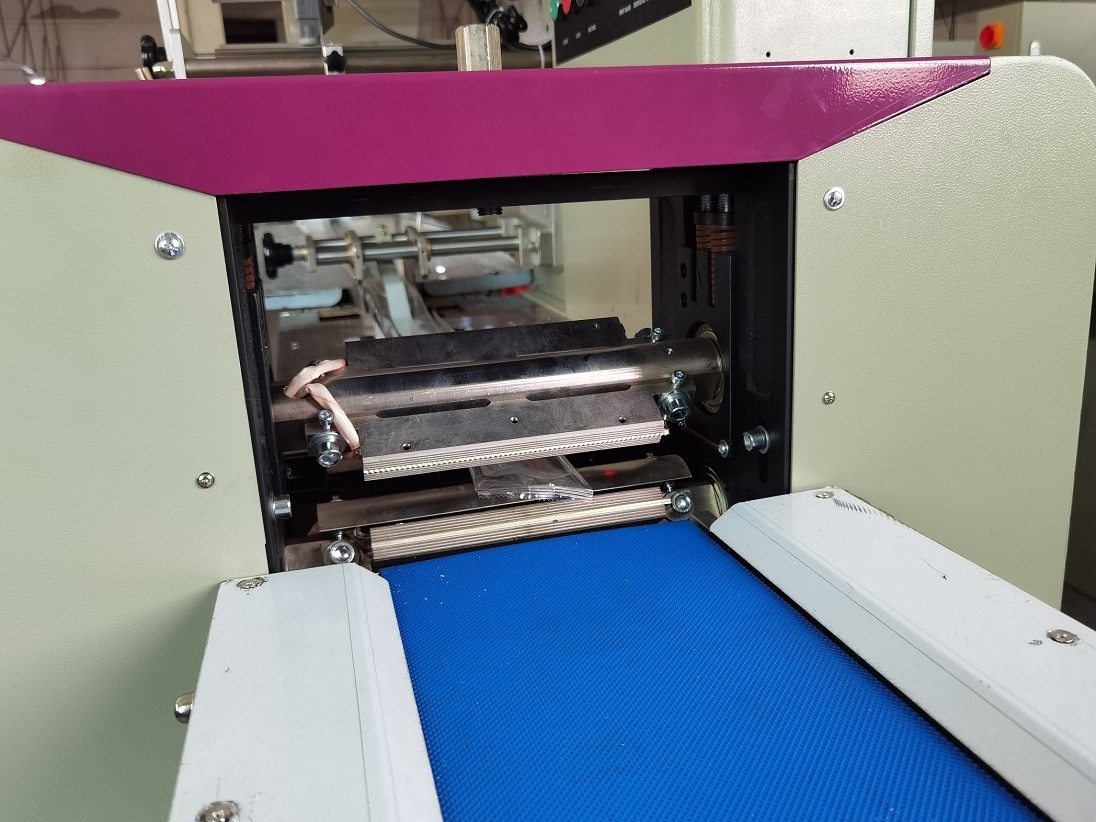

Main Features

New design, beautiful appearance, more reasonable structure, more advanced technology

Imported PLC computer control system, color touch screen, easy to operate, intuitive and efficient

Imported film transport system, imported color standard sensor, accurate positioning, excellent performance, beautiful packaging

Multiple automatic alarm protection functions to minimize damage

Diversified bag shape, can provide customers with pillow bag, pocket, hole bag, joint and so on

Touch screen and stable and reliable PLC control, bag-making, metering, filling, sealing, coding, bag-cutting one-time completion

The film is controlled by servo motor to realize high precision positioning and accurate size

External film release mechanism is adopted to facilitate the installation of packaging film

Vertical sealing and sealing process, automatic adjustment of deviation, greatly reducing labor intensity

Shipping a whole set of the machine:

1. Preparing and checking the toolbox wearing part and the manual book.

2.Cleaning the dust and the scrap after testing the machine with the air pump.

3. Disassemble some certain part of the machine.

4. All the disassemble part, toolbox, main machine wrap by film

5.There will have screw fix themachine at the bottom of the wooden case 6.If any special requirements, we will pack it as requested.