- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FC510

-

Name:

-

PET polyethylene terephthalate

-

IV value:

-

0.8/0.82/0.84

-

Packing:

-

1100kgs/bag

-

MOQ:

-

10 Tons

-

Sample:

-

Avialable

-

Usage:

-

carbonated drinks and 3-gallon, 5-gallon big bottles

-

Feature2:

-

good color value, stable viscosity and good for processing

-

Processing method:

-

low temperature processing

-

Color:

-

Natural Color

Quick Details

-

color:

-

Natural color

-

Shape:

-

resin

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FC510

-

Name:

-

PET polyethylene terephthalate

-

IV value:

-

0.8/0.82/0.84

-

Packing:

-

1100kgs/bag

-

MOQ:

-

10 Tons

-

Sample:

-

Avialable

-

Usage:

-

carbonated drinks and 3-gallon, 5-gallon big bottles

-

Feature2:

-

good color value, stable viscosity and good for processing

-

Processing method:

-

low temperature processing

-

Color:

-

Natural Color

Products Description

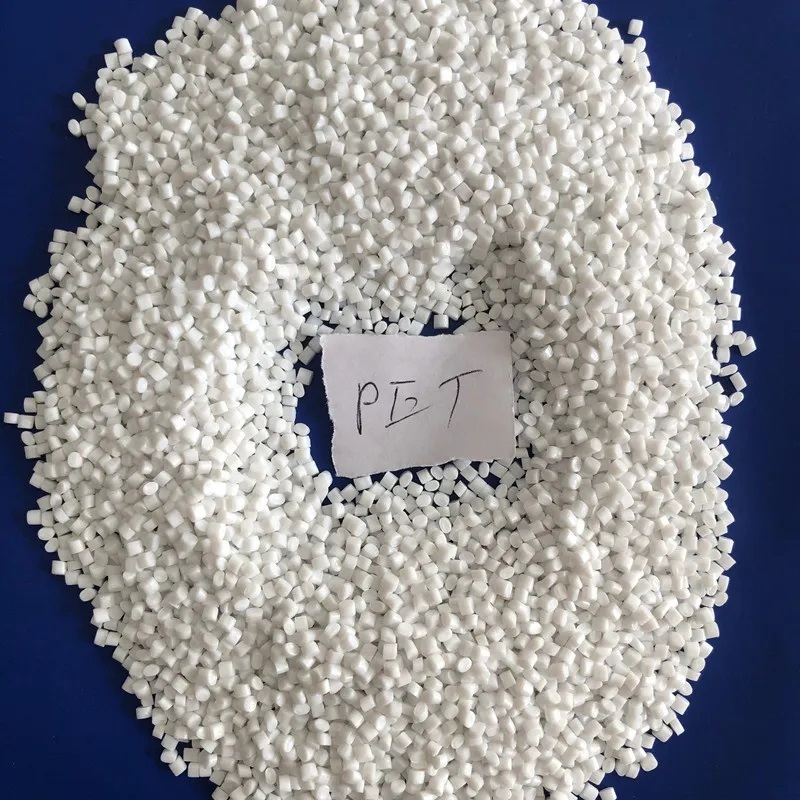

Introduction to PET plastic

PET plastic raw material, polyethylene terephthalate, is the most important variety of thermoplastic polyester, commonly known as PET or PEIT (hereinafter referred to as PET), commonly known as polyester resin. It is a condensed polymer of terephthalic acid and ethylene glycol, collectively referred to as thermoplastic polyester or saturated polyester along with PBT.

Advantages of PET as a packaging material:

1. It has good mechanical properties, with an impact strength 3-5 times that of other films, and good bending resistance.

2. Oil resistant, fat resistant, acid and alkali resistant, and resistant to most solvents.

3. It has excellent resistance to high and low temperatures and can be used for a long time within the temperature range of 120 ℃. It can withstand high temperatures of 150 ℃ and low temperatures of -70 ℃ for short-term use, and its mechanical properties are minimally affected by high and low temperatures.

4. Gas and water vapor have low permeability and excellent resistance to gas, water, oil, and odor.

5. High transparency, can block ultraviolet rays, and has good gloss.

6. Odorless, good hygiene, can be directly used for food packaging

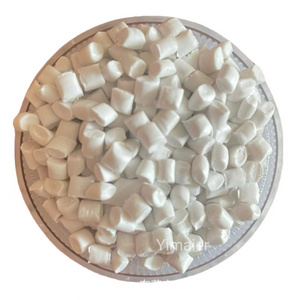

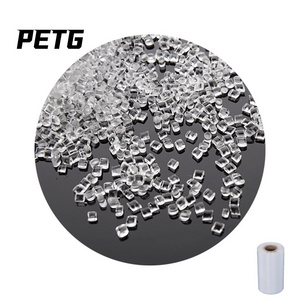

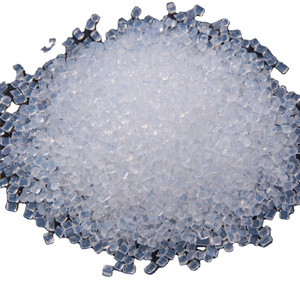

Details Images

Product Paramenters

Applications

|

PET CR-8816

|

PET CR-8816 is for packing bottles, like pure water, natural mineral water, distilled water, drinking water

|

|

|

|

|||

|

PET CR-8863

|

PET CR-8863 is for small-package edible oil bottles, liquor bottles, medicine bottles, cosmetics bottles, PET sheets

|

|

|

|

|||

|

PET CR-8839

|

PET CR-8839 is for hot-filling bottles, like tea drinks, fruit-juice drinks and other medium type drinks

|

|

|

|

|||

|

PET CR-8828

|

PET CR-8839 is for hot-filling bottles, like tea drinks, fruit-juice drinks and other medium type drinks

|

|

|

|

|||

|

PET CR-8828F

|

PET CR-8828F is fast reheat chip for packing bottles of carbonated and soft drinks.

|

|

|

|

|||

IV 0.80 Water Bottle Grade PET Resin

This PET Chips are suitable for making the packing bottles for purified water, natural mineral water, distilled water and drinking water,It also can be used to make Sheets for food containers.

IV 0.85 CSD Bottle Grade PET Resin

It can be Used in the production of making packing bottles for carbonated soft drink like cola and 3-gallon big bottles.

IV 0.83 Edible Oil Grade PET Resin

This PET Chips are invited and produced according to the higher strength, isolation, transparency and better processing features. It is characterized by low content of heavy metal and acetaldehyde, good color value and superior stable viscosity.It can satisfy the thicker and more varieties processing requirements of small package edible oil bottles, liquor bottles, medicine bottles and sheets.

IV 0.80 Hot Filled Grade PET Resin

This PET Chip is TPA-based polyethylene terephthalic homopolymer. lt is characterized by its property of thermal resistance, and is designed specially for hot-filling bottles like tea, fruit-juice and other drinks that required to be hot filled for sterilization

Certifications

Packing and shipping

Usually 1100kg/bag,

Hot Searches