- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Resda

-

Model Number:

-

S70-S930

-

Use:

-

Metal Shot Blasting Process

-

Color:

-

Black

-

Material:

-

Steel

-

Shape:

-

Round

-

MOQ:

-

1 Ton

-

Hardness:

-

40-50HRC

-

Advantage:

-

Economic Efficiency

-

Dimater:

-

0.2-2.0mm

-

Standard:

-

SAE J444

-

Sample:

-

Sample Provided

-

Package:

-

25kg/bag

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

10-100

-

Warranty:

-

1 year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Resda

-

Model Number:

-

S70-S930

-

Use:

-

Metal Shot Blasting Process

-

Color:

-

Black

-

Material:

-

Steel

-

Shape:

-

Round

-

MOQ:

-

1 Ton

-

Hardness:

-

40-50HRC

-

Advantage:

-

Economic Efficiency

-

Dimater:

-

0.2-2.0mm

-

Standard:

-

SAE J444

-

Sample:

-

Sample Provided

-

Package:

-

25kg/bag

Steel Shot For Shot Blasting Machines

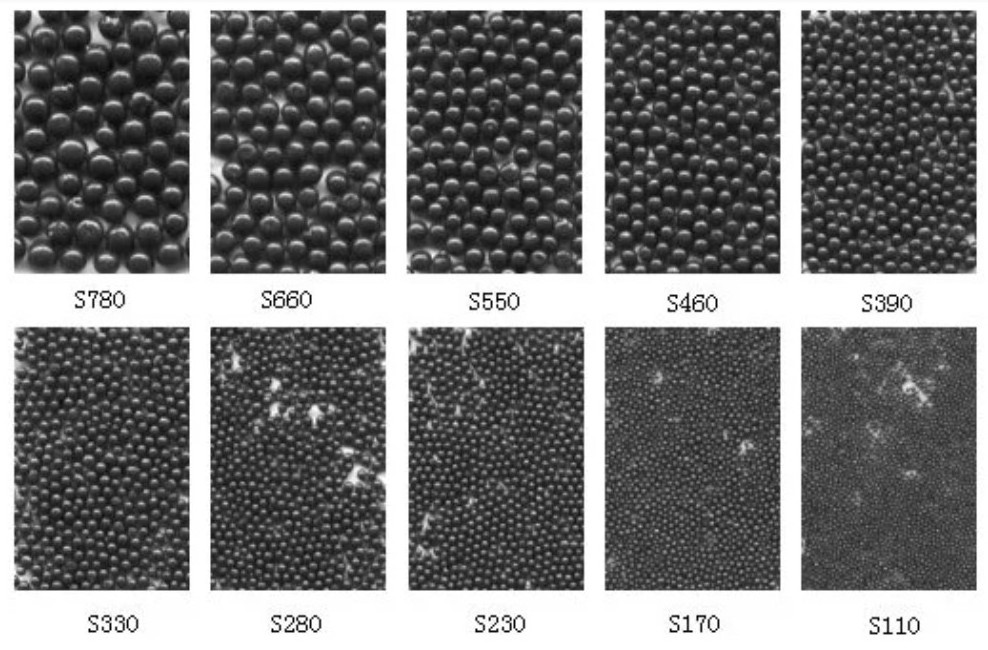

Steel Shots Model : S70/S110/S170/S230/S330/S390/S460/S550/S660/S780/S930

Steel Shots Model : S70/S110/S170/S230/S330/S390/S460/S550/S660/S780/S930

Steel Grit Abrasive Blasting

Steel Grit Grades:G10 ,G12, G14, G16, G18, G25, G40, G70, G80, G120

Steel Grit Grades:G10 ,G12, G14, G16, G18, G25, G40, G70, G80, G120

Product Application:

Blast cleaning: Used for blast cleaning of casting, die-casting, forging; sand removal of casting, steel plate, H type steel, steel structure.

Rust removal: Rust removal of casting, forging, steel plate, H type steel, steel structure.

Shot peening: Shot peening of gear, heat treated parts.

Shot blasting: Shot blasting of profile steel, ship board, steel board, steel material,steel structure.

Pre-treatment: Pre-treatment of surface, steel board, profile steel, steel structure before painting or coating.

|

C

|

0.80-1.20

|

|

Si

|

0.35-1.20

|

|

Mn

|

0.60-1.20

|

|

S

|

≤0.05

|

|

P

|

≤0.05

|

|

Hardness

|

HRC40-50

|

|

Micro structure

|

Homogeneous tempered Martensite or Troostite

|

|

Density

|

≥7.20g/cm3

|

Product packaging

Strict Test Before Shipping

Certifications

Our Advantages

Customers&Exhibition

FAQ

Hot Searches