- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1960*925*1120

-

Weight:

-

1605

-

Power (kW):

-

5.5

-

Crimping Range:

-

0-3.5inch

-

Die Supporting:

-

Dia14/16/19/22/26/30/34/39/45/51/57/63/69/84/92/100/108/116

-

Net Weight:

-

1592kgs

-

Gross Weight:

-

1605kgs

-

Dimension:

-

1860*925*1120

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GT

-

Voltage:

-

380V, 380V/5.5KW

-

Dimension(L*W*H):

-

1960*925*1120

-

Weight:

-

1605

-

Power (kW):

-

5.5

-

Crimping Range:

-

0-3.5inch

-

Die Supporting:

-

Dia14/16/19/22/26/30/34/39/45/51/57/63/69/84/92/100/108/116

-

Net Weight:

-

1592kgs

-

Gross Weight:

-

1605kgs

-

Dimension:

-

1860*925*1120

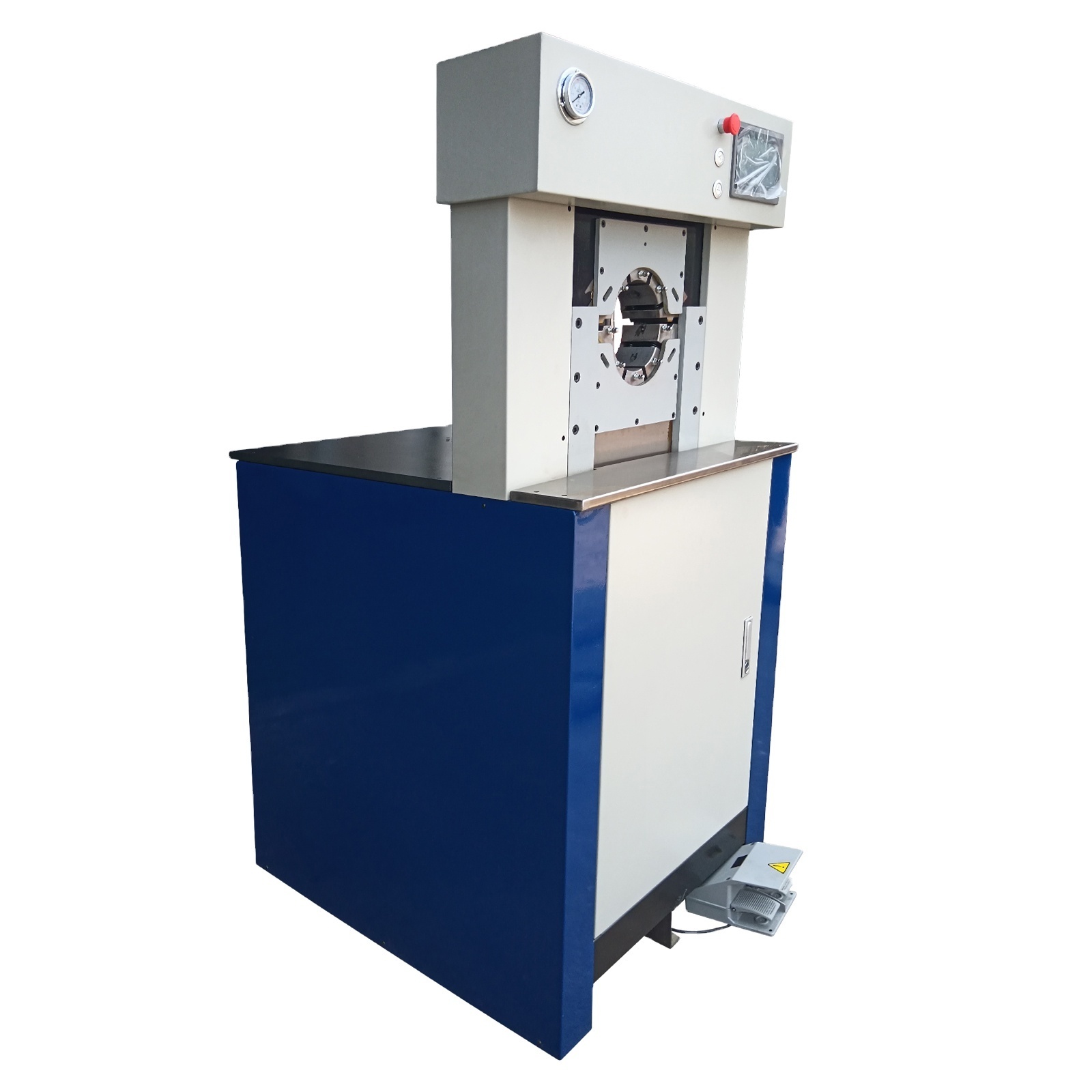

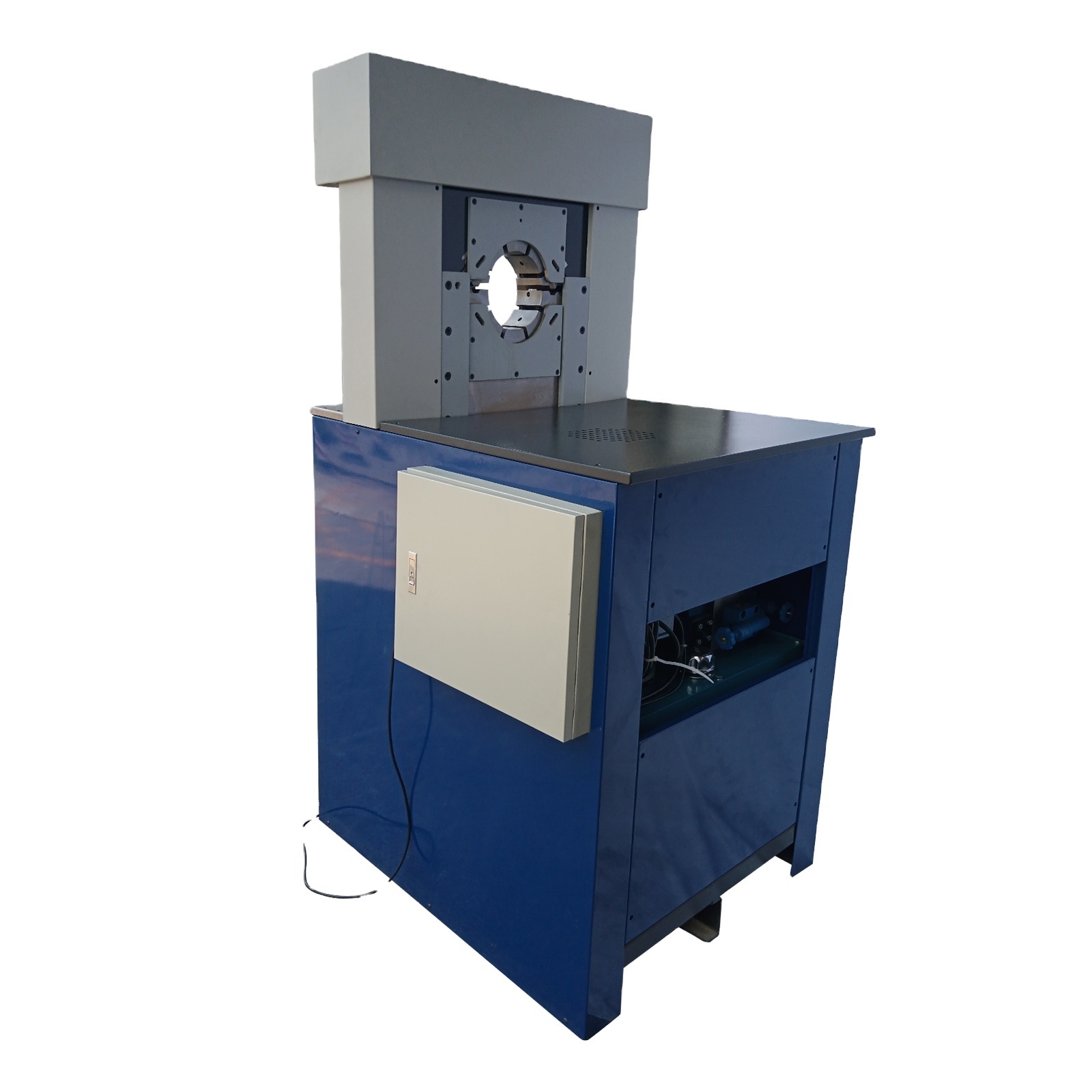

GT-90 Hydraulic-Hose-Crimping-Machine Crimping Machine Hydraulic Hose dx68 Hose Crimping Machine

What is Hose crimping machine?

The term " hose crimping machine ", also known as pipe pressing machine, pipe locking machine, pipe throat machine, pipe crimping machine, or tube pressing machine, refers to a hydraulic integrated equipment specialized in joining pipe fittings with metal components. It typically operates at voltages of 220V or 380V, with specifications ranging from 1 to 10 inches. Our company offers a diverse range of models, specifications, and styles of pipe pressing machines, each serving different purposes.

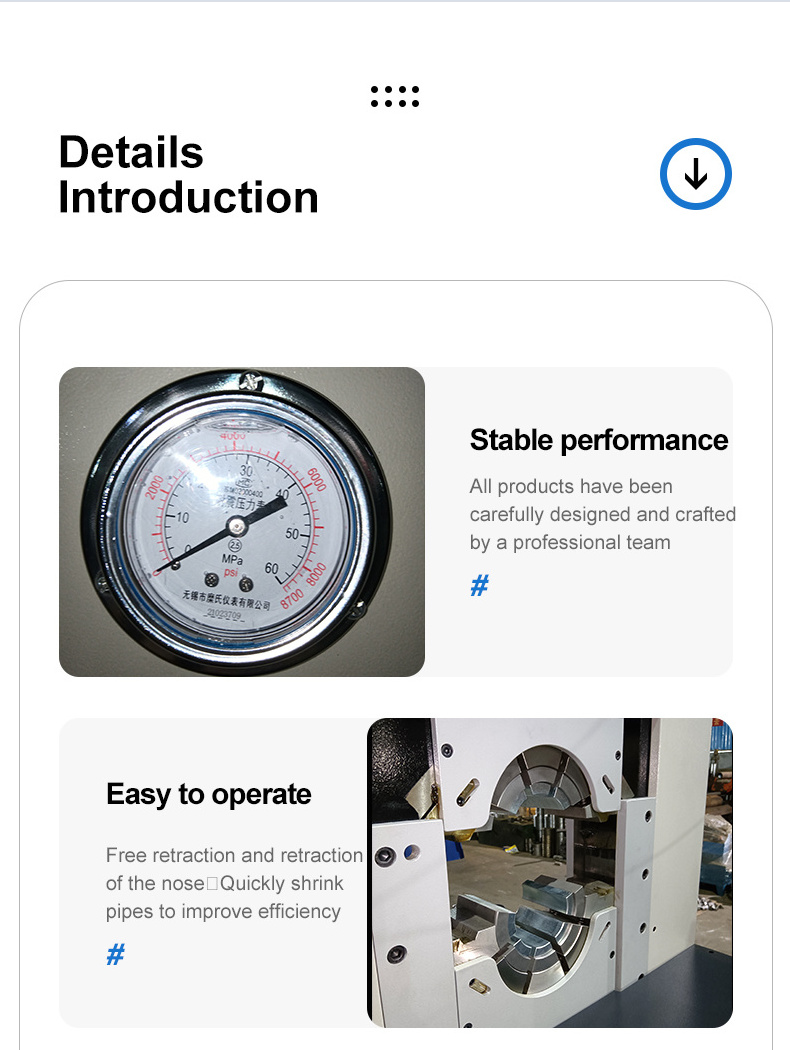

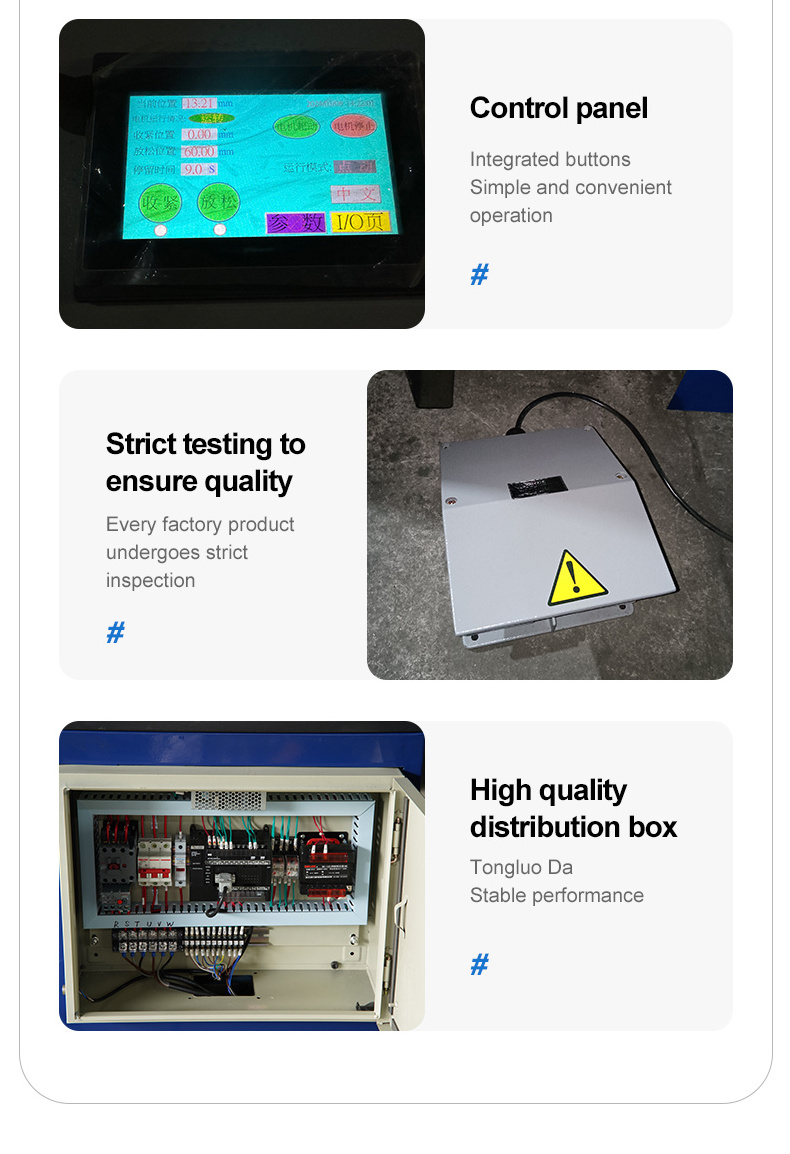

Hydraulic Hose Crimping Machine O perational principle

The hydraulic pump is installed within the oil tank, immersed in hydraulic oil to achieve efficient heat dissipation and silence. When driven by the motor, the pump outputs hydraulic oil, driving the reciprocating motion of pistons within the crimping cylinder. This action causes radial contraction of the die holder, resulting in the compression of the outer sleeve of the hose fitting. Once the contraction reaches the preset tolerance, the crimping automatically ceases. Subsequently, upon directional change initiated by the electromagnetic directional valve, the pistons within the cylinder reverse their motion, causing the die to open, thereby completing the crimping process on the hose.

Application Fields of Pipe Pressing Machine

Primarily utilized for crimping pipes to metal fittings or reducing steel pipes, including but not limited to high and low-pressure oil pipes, transmission pipes, engine oil pipes, brake pipes, air conditioning pipes, power steering pipes, throttle cables, gearshift cables, fuel supply pipes, high-pressure car wash pipes, welding gun pipes, gas pipes, air compressor pipes, specialized mining gas pipes, medical gas pipes, welding gas pipes, washing machine hoses, bathroom hoses, plumbing pipes, PTFE pipes, braided hoses, wire tubes, steel wire ropes, bridge water supply pipes, airbag pipes, shock absorbers, concrete pump pipes, rubber hoses, scaffolding, broom handles, greenhouse frame, mosquito net steel pipe brackets, fire hoses, and the crimping of rubber hoses, silicone hoses, fiber tubes, plastic tubes, PTFE tubes, and braided tubes. Widely applied in industries such as automotive, construction machinery, hydraulic machinery, welding and cutting equipment, oil fields, mining areas, construction, bathroom decoration, firefighting, mining, and pipe fittings.