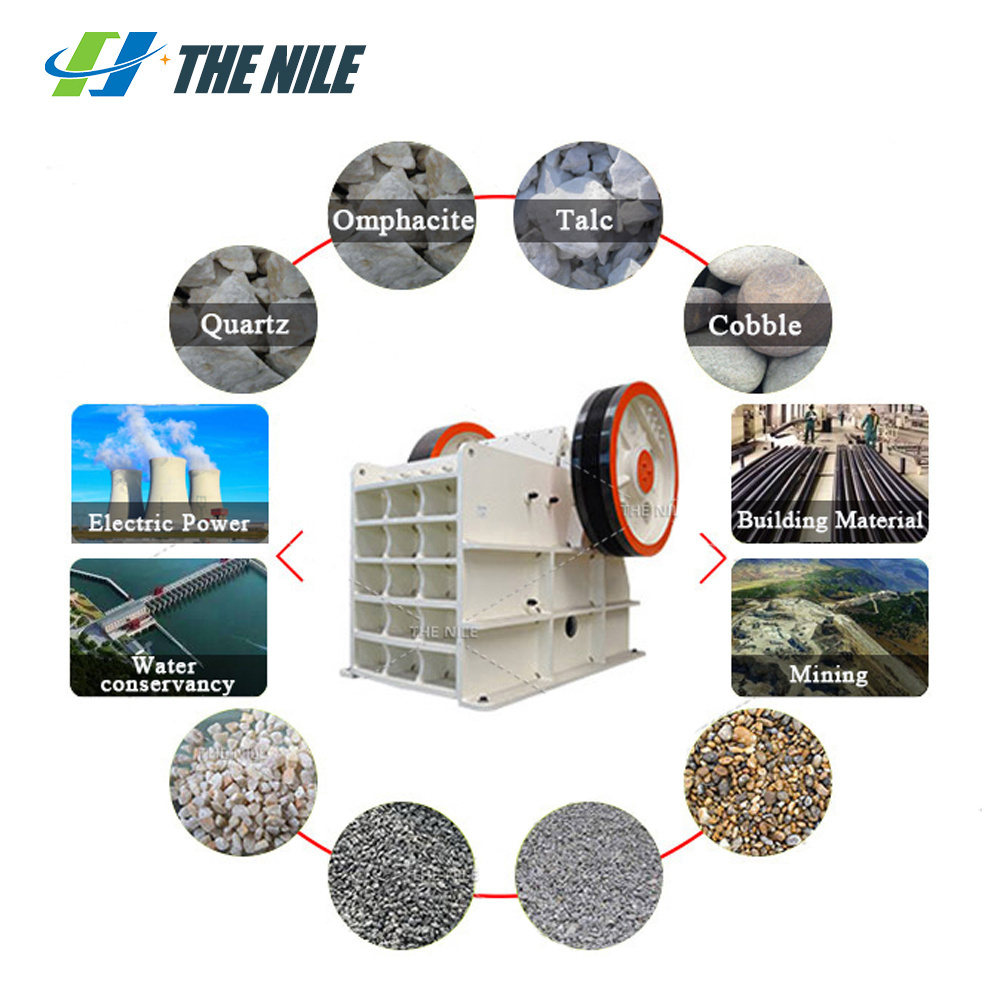

Jaw crusher is mainly used to crush hard and medium hard stones in stone mining, metallurgy industry, building material, highway, railway, stone industry, etc.

Max. anti-pressure strength of material to be crushed is 320MPa.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

The nile

-

Dimension(L*W*H):

-

1000*870*990

-

Weight:

-

1.5 KG

-

Marketing Type:

-

New Product 2023

-

After-sales Service Provided:

-

Overseas Engineer Supply

-

Model:

-

PE 150*250

-

Max. Feeding Size:

-

125mm

-

Discharging Range:

-

10-40mm

-

Capacity:

-

1-3t/h

-

Rotation Speed:

-

260 r/min

-

Ware Parts:

-

Available

-

Local Service Location:

-

Kenya

-

Certification:

-

ISO CE

Quick Details

-

Application:

-

Mining

-

Capacity(t/h):

-

1-3

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

The nile

-

Dimension(L*W*H):

-

1000*870*990

-

Weight:

-

1.5 KG

-

Marketing Type:

-

New Product 2023

-

After-sales Service Provided:

-

Overseas Engineer Supply

-

Model:

-

PE 150*250

-

Max. Feeding Size:

-

125mm

-

Discharging Range:

-

10-40mm

-

Capacity:

-

1-3t/h

-

Rotation Speed:

-

260 r/min

-

Ware Parts:

-

Available

-

Local Service Location:

-

Kenya

-

Certification:

-

ISO CE

Product Description

Jaw Crusher

Features

High ratio of crushing;

Simple structure,Reliable working condition;

Easy maintenance, Low operating cost;

Simple structure,Reliable working condition;

Easy maintenance, Low operating cost;

Homogeneous final product size;

Discharge size can be adjusted.

Discharge size can be adjusted.

Application

Processing Material:

River Gravel, Granite, Basalt, Quartz Stone, Iron Ore, Diabase, Limestone, Coal Gangue

River Gravel, Granite, Basalt, Quartz Stone, Iron Ore, Diabase, Limestone, Coal Gangue

How to Work

The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft.

The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet.

The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet.

Technical Data

|

Model

|

Max.Feeding Size

(mm)

|

Discharging Size

(mm)

|

Capacity

(t/h)

|

Motor Power

(kw)

|

Weight

(t)

|

|

PE150*250

|

125

|

10-40

|

1-3

|

5.5

|

0.7

|

|

PE250*400

|

210

|

20-60

|

5-20

|

15

|

2.8

|

|

PE400*600

|

340

|

40-100

|

16-60

|

30

|

7

|

|

PE400*900

|

340

|

40-100

|

40-110

|

55

|

7.5

|

|

PE500*750

|

425

|

50-100

|

40-110

|

55

|

12

|

|

PE600*900

|

500

|

65-160

|

50-180

|

75

|

17

|

|

PE750*1060

|

630

|

80-140

|

110-320

|

90

|

31

|

|

PE900*1200

|

750

|

95-165

|

220-450

|

160

|

52

|

|

PE1000*1200

|

850

|

195-265

|

315-500

|

160

|

55

|

|

PE1200*1500

|

1020

|

150-350

|

400-800

|

220

|

93

|

|

PE1500*1800

|

1200

|

220-350

|

500-1000

|

280

|

122

|

|

PEX150*750

|

120

|

18-48

|

8-25

|

15

|

3.8

|

|

PEX250*750

|

210

|

15-60

|

13-35

|

30

|

6.5

|

|

PEX250*1000

|

210

|

15-60

|

16-52

|

37

|

7

|

|

PEX250*1200

|

210

|

15-60

|

20-61

|

45

|

9.7

|

|

PEX300*1300

|

250

|

20-90

|

16-105

|

55

|

15.6

|

Product Details

Customer Site

Packing&Shipping

Hot Searches