- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V220V

-

Power:

-

2.2KW

-

Dimension(L*W*H):

-

2300*1500*1800mm

-

Weight:

-

1500 KG

-

Name:

-

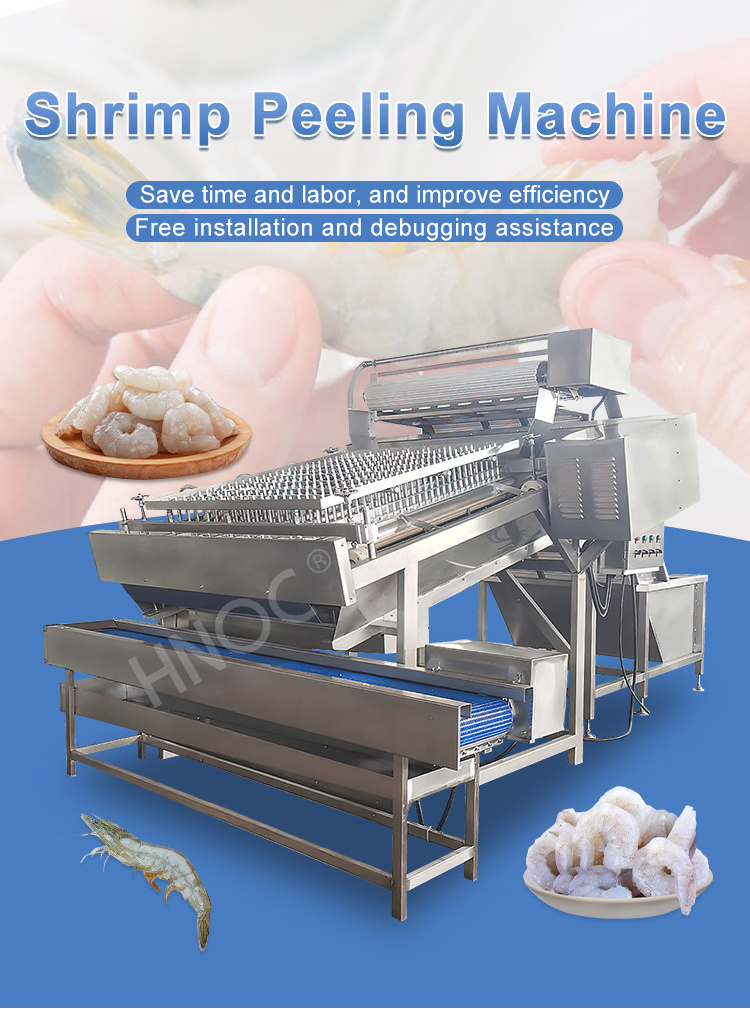

Shrimp peeling machine

-

Material:

-

304 stainless steel

-

Usage:

-

industrial use

-

Function:

-

peel and clean shrimp

-

capacity:

-

80/150/300kg per hour

-

Keyword:

-

Shrimp peeling machine

-

Advantage:

-

high peeling rate and water recycling

-

Full set machine include:

-

shrimp conveying,shelling and conveying

-

MOQ:

-

1PC Shrimp peeling machine

-

After sale service:

-

one year warranty

Quick Details

-

Production Capacity:

-

100%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNOC

-

Voltage:

-

380V220V

-

Power:

-

2.2KW

-

Dimension(L*W*H):

-

2300*1500*1800mm

-

Weight:

-

1500 KG

-

Name:

-

Shrimp peeling machine

-

Material:

-

304 stainless steel

-

Usage:

-

industrial use

-

Function:

-

peel and clean shrimp

-

capacity:

-

80/150/300kg per hour

-

Keyword:

-

Shrimp peeling machine

-

Advantage:

-

high peeling rate and water recycling

-

Full set machine include:

-

shrimp conveying,shelling and conveying

-

MOQ:

-

1PC Shrimp peeling machine

-

After sale service:

-

one year warranty

Product Description

Introduction

The shrimp peeling machine is suitable for shelling shrimp during the shrimp processing process. The working principle is based on the principle of an plug-in cleaning system, which has the characteristics of shelling efficiency and high yield.

Application

The shrimp peeling machine is suitable for various industries such as catering, shrimp peeling factories, restaurants, and shrimp processing factories.

Features

1.

Compared with the traditional processing method, it saves a lot of manpower and improves the production efficiency, which is suitable for the processing of large quantities of shrimp.

2.

The system has a novel concept, compact design, reasonable structure, large processing output with a small equipment

footprint, and improves the utilization efficiency of the plant.

3. Made of stainless steel, all parts or materials meet HACCP hygienic requirements.

4. The system has a high degree of automation, open structure design, sanitation and easy cleaning, and easy operation and maintenance.

footprint, and improves the utilization efficiency of the plant.

3. Made of stainless steel, all parts or materials meet HACCP hygienic requirements.

4. The system has a high degree of automation, open structure design, sanitation and easy cleaning, and easy operation and maintenance.

Finished Product Display

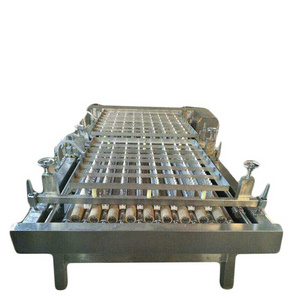

Parameter

|

Model

|

HNOC-A300

|

HNOC-B150

|

HNOC-C80

|

HNOC-D50

|

|

Capacity

|

300kg/h

|

150kg/h

|

80kg (raw shrimp)/h

|

40-50kg/h

|

|

Material

|

SUS 304 stainless steel

|

SUS 304 stainless steel

|

SUS 304 stainless steel

|

SUS 304 stainless steel

|

|

Power

|

4.0KW

|

3.0KW

|

2.2KW

|

1.5KW

|

|

Voltage

|

220/380V/415/440 (with variable frequency)

|

220/380V (with variable frequency)

|

220/380V (with variable frequency)

|

220/380V

|

|

Equipment size (length * width * height)

|

Supporting hoist

2700 * 1650 * 2460mm

Shell peeling machine 3600 * 2260 * 2200mm

Shrimp conveyor

2500 * 600 * 800mm

|

Supporting hoist

2200 * 1500 *2100mm

Shell peeling machine 2300 * 2060 * 1800mm

Shrimp conveyor 2000 * 600 * 800mm

|

Supporting hoist

2200 * 1200 * 2100mm

Shell peeling machine 2300 * 1500 *1800mm

Shrimp conveyor

2000 * 600 * 800mm

|

Shell peeling machine: 1800 * 1400 * 1650mm

|

Product Details

Product Photograph

Related Products

Hot Searches