- Product Details

- {{item.text}}

Quick Details

-

Graphic Format Supported:

-

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

-

Cooling Mode:

-

WATER COOLING

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GoodCut CNC

-

Dimension(L*W*H):

-

1200*900mm 1300*900mm 1400*1000mm

-

Weight (KG):

-

800 KG

-

Product name:

-

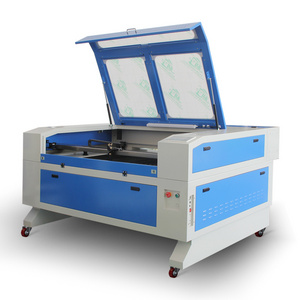

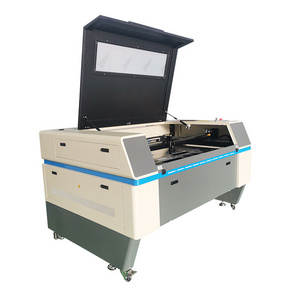

GoodCut CNC co2 laser cutting and engraving machine 80w 100w 130w

-

Water chiller:

-

CW3000 CW5000 CW5200

-

Motor:

-

Leadshine stepper motor

-

Driver:

-

Leadshine driver

-

Control system:

-

Ruida Control System/Leetro/Topwisdom

-

Laser tube type:

-

Sealed CO2 Glass Tube

-

Laser tube power:

-

80W 100W 130W

-

Laser tube brand:

-

EFR RECI

-

Transmission:

-

belt/rack and pinion, PMI guide rails

Quick Details

-

Engraving Area:

-

1400*1000mm

-

Laser Type:

-

CO2

-

Engraving Speed:

-

75000mm/min

-

Graphic Format Supported:

-

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

-

Cooling Mode:

-

WATER COOLING

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GoodCut CNC

-

Dimension(L*W*H):

-

1200*900mm 1300*900mm 1400*1000mm

-

Weight (KG):

-

800 KG

-

Product name:

-

GoodCut CNC co2 laser cutting and engraving machine 80w 100w 130w

-

Water chiller:

-

CW3000 CW5000 CW5200

-

Motor:

-

Leadshine stepper motor

-

Driver:

-

Leadshine driver

-

Control system:

-

Ruida Control System/Leetro/Topwisdom

-

Laser tube type:

-

Sealed CO2 Glass Tube

-

Laser tube power:

-

80W 100W 130W

-

Laser tube brand:

-

EFR RECI

-

Transmission:

-

belt/rack and pinion, PMI guide rails

GoodCut CNC co2 laser cutting and engraving machine 80w 100w 130w 150w Laser Cutter

Description:

1. By making groves on the machine structure, the machine strength has been improved and the size of machine is more preciser than before.

2. The machine can be dismantled, which make the machine easily pass through the door.

3. The reflectors have been fixed. So it is easier to adjust the laser path.

4. Adding new parts to the ventilation system, which makes sure the ventilation is more smooth.

5. Added warning light make the machine more safer in operation.

6. Z axis adopt the belt transmission system. So the machine makes little noise in operation.

Parameter:

|

Laser power |

60W/80W/100W/120W/150W/180W |

||

|

Laser Types |

Hermetic And Detached CO2 Laser Tube |

||

|

Engraving speed(mm/min) |

0-75000 |

||

|

Cutting speed(mm/min) |

0-40,000 |

||

|

Minimum letter |

English 1 x 1mm |

||

|

Location precision |

≤0.01mm |

||

|

Resetting positioning accuracy |

0.01mm |

||

|

Driving system |

Stepper (Hybrid servo &Panasonic servo are optional) |

||

|

Software |

RDworks V8 (compatible with CorelDraw &AutoCAD) |

||

|

360°slope engrave |

Yes |

||

|

Power supply |

AC 220V/50Hz~60HZ (110V is also available) |

||

|

Operating temperature |

0 - 45℃ |

||

|

Operating humidity |

5 - 95% |

||

|

Laser output control |

1-100% control panel and software setting |

||

|

Highest scanning precision |

50-1000DPI |

||

|

Compatible software |

CorelDraw, AutoCAD, Photoshop |

||

|

Auxiliary Devices |

Exhaust fan and Exhaust pipe |

||

|

Cooling mode |

Water-cooling and protection system CW3000, CW5000,CW5200 |

||

|

Graphic format supported |

BMP, CIF, JPEG, TGA, TIFF, PLT, AI, DXF, DST (TIANDAO Embroidery Software), DWG, CDR, etc |

||

Feature:

1.Laser Machine Software to control the cutting and engraving process of your work, controlling speed, power, and resolution. Capable of engraving vector and picture files directly. This software is compatible with a large variety of design programs (Such as CorelDraw, PhotoShop, AutoCAD, TAJIMA,Artcut, and more) and files: BMP, PLT, DST, DXF, AI, JPG, GIF, PGN, TIF formats.

2. Laser machine software, operation and installation manuals.

3. Unlimited technical support, over the phone, Skype or email.

4.Free training of equipment operation and maintenance with our Technical Support Engineer at our premises, over the phone or Skype.

5. Tool kit for preventive and corrective maintenance.

6. Warranty: one year for electronics and mechanical components and three months for the laser tube and consumables. (Reci tube 10 months)

7.Guidance & support with our Technical Support Engineers on the installation and setup of your machine.

Advantages:

1. Auto-feeding Table

It will transport material on the table automatically and also can be used manually by controller.

2. Auto-feeding Device

It is equiped with a stepper motor,which can supply power to rotate roller so that textile can be fed full automatically.

3. Industrial water chiller with better working performance than water pump

There are CW3000, CW5000, CW5200

4. DSP control: Ruida RD controller

high speed, stability, anti-interference ability.

Advanced USB control and Flash Disk (U Disk) off-computer control system are optional.

5. We use Taiwan HIWIN linear rail for transmission,to ensure high precision,faster speed,lower noise,and its lifetime is 10 times longer than common rail ways.

It adopts imported precise and fast speed linear guide rail to increase the machine work accuracy. modern auto feeding system with strong dense stainless net structure working table, highly improves the cutting precision on materials.

Applicable Material :

|

1.Industrial textile: filter cloth, bolting cloth, filter fabric, nonwoven, glass fiber, felt, synthetic fibre, fabric ducting, polypropylene (PP), polyethylene (PE), polyester (PES), polyamide (PA), cement packing, geotextile, coated fabric, PVC fabic, sponge, insulating material and other industrial flexible materials.

|

|

2.Non-woven fabrics for health & medical: insulating material, glass fibre, polyester fibre, Microfiber, Cleanroom Wiper, Glasses cloth, Micro-fiber Wiper, non-dust cloth, clean wiper, paper diaper, etc.

|

|

3.Home furnishing fabrics: upholster, carpet, mat, floor rug, mattress, curtain, doormat, valance, wall paper, tablecloth, bed sheet, bedspread, counterpane, dust cover, sofa fabric, etc

|

|

4.Garment fabrics: sportswear, swimwear, diving suit, exposure suit, liner, lining, adhesive interlining, wadding piece, case-hardened cotton, synthetic leather, genuine leather, etc. |

| 5.Automotive interiors: car seat cover, car cushion, car mat, car carpet, car rug, pillowcase, air bag, auto dustproof cover, seat belt (safety belt), etc. |

Nonmetal material such as leather, clothing, fabric, textile, thin film, canvas, nonwovens, etc.

Our service:

* Pre-sale and In-sale

Consulting service, sample’s process experiment, equipment selection, training to the engineers and the user of the buyer.

Training:

After the acceptance check by the buyer, we offer training and maintenance guidance.

Training content:

1.Laser safety protection knowledge, the basic principles of lasers and laser marking machine construction.

2.Control system operating skills, equipment operation and precautions.

3.Equipment routine maintenance, laser adjustment and parts replacement operation skills.

* After-sale:

1.24 months guarantee for whole machine free of charge, except tube and lens 10 months

2.Perfect 7*24 hours technical support by e-mail

3.Calling or online service, professional training to your workers

4.Use friendly English software, user manual and detailed Videos/CD

5.Priority to become our agent in your city,we offer you our factory price