<1>All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

<2>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3> 304/316 stainless steel washing pump

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HY-FILLING

-

Dimension(L*W*H):

-

5m*'5m*3m

-

Weight:

-

3T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Filling material:

-

Flowing Liquid

-

Material:

-

SUS304

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

2000-30000bph

-

Filling speed:

-

Adjustable

-

Filling Accuracy:

-

0.5%

-

Filling range:

-

200-2000ml

-

Filling type:

-

Quantity Filling

-

Usage:

-

Beverage Packaging

-

Certification:

-

CE

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Water

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HY-FILLING

-

Dimension(L*W*H):

-

5m*'5m*3m

-

Weight:

-

3T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Filling material:

-

Flowing Liquid

-

Material:

-

SUS304

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

2000-30000bph

-

Filling speed:

-

Adjustable

-

Filling Accuracy:

-

0.5%

-

Filling range:

-

200-2000ml

-

Filling type:

-

Quantity Filling

-

Usage:

-

Beverage Packaging

-

Certification:

-

CE

Recommend Products

Product Description

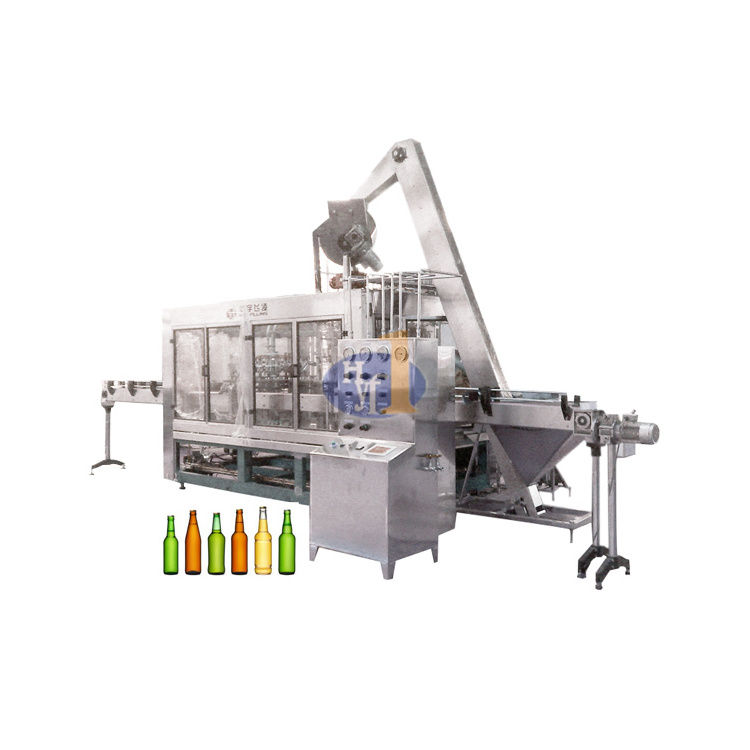

Rinsing-Filling-Capping 3-in-1 Monoblock

This CGN Wash-filling-capping 3-in-1unit: Beverage Machinery is used to produce polyester bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery. Beverage Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

Details Images

Washing part

Filling part

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

Capping part

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

|

Main

composition

|

|

|

|

PLC

|

Mitsubishi, Siemens

|

|

|

Touch screen

|

Mitsubishi, Siemens, PROFACE

|

|

|

Frequency converter

|

Mitsubishi, Siemens, Danfoss

|

|

|

Air switch

|

Schneider

|

|

|

Contactor

|

Siemens

|

|

|

Breaker

|

Siemens

|

|

|

Photoelectric switch

|

Omron, Keyence, P+F

|

|

|

Approach switch

|

Truck

|

|

|

Main bearing

|

NTN

|

|

|

Lubrication bearing

|

IGUS

|

|

|

Sealing

|

Sealtech

|

|

|

Pneumatic components

|

Camozzi

|

|

Product Paramenters

|

Model

|

CGN 12-12-4

|

CGN 16-16-5

|

CGN 18-18-6

|

CGN 24-24-8

|

CGN 32-32-10

|

CGN 40-40-12

|

|||||

|

Capacity

0.5L/bottle/h |

3000- 4000

|

4000- 6000

|

6000- 8000

|

8000- 12000

|

13000- 15000

|

16000- 18000

|

|||||

|

Suitable bottle

|

PET Circular or square

|

|

|

|

|

|

|||||

|

Bottle diameter

|

50-115 mm

|

|

|

|

|

|

|||||

|

Bottle

height |

160-320 mm

|

|

|

|

|

|

|||||

|

Compressed air pressure

|

0.3-0.7 Mpa

|

|

|

|

|

|

|||||

|

Washing

water's pressure |

>0.06Mpa <=0.2Mpa

|

|

|

|

|

|

|||||

|

Total power

|

4.4

|

4.4

|

4.4

|

5.2

|

6.2

|

7.8

|

|||||

Auxiliary Equipment

The Reverse Osmosis device is an equipment to purify the saline water with the action of pressure difference of semi-permeable membrane. It is called reverse osmosis, as it is counter to natural penetration direction. Difference materials have different osmotic pressures.

Linear blowing machine

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

PE film shrink

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

robot palletizer

The robot palletizer is widely used in food, beverage, beer and daily chemical products. It covers small floor space, of large production capacity, fully automatic working. It could handle different boxes. Whole processing is full automatically come true under windows interface program system,

Hot Searches