- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jinling

-

Voltage:

-

AC380/220V

-

Power:

-

120KW

-

Dimension(L*W*H):

-

15000*6000*5000mm

-

Weight:

-

2000 kg

-

Warranty:

-

1year

-

Marketing Type:

-

paper making machine

-

Name:

-

toilet paper, tissue paper making machine

-

Capacity:

-

2-3 tons/day

-

Output paper:

-

jumbo rolls toilet tissue paper

Quick Details

-

Production Capacity:

-

5-50 t/d

-

Processing Type:

-

Toilet tissue paper making machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jinling

-

Voltage:

-

AC380/220V

-

Power:

-

120KW

-

Dimension(L*W*H):

-

15000*6000*5000mm

-

Weight:

-

2000 kg

-

Warranty:

-

1year

-

Marketing Type:

-

paper making machine

-

Name:

-

toilet paper, tissue paper making machine

-

Capacity:

-

2-3 tons/day

-

Output paper:

-

jumbo rolls toilet tissue paper

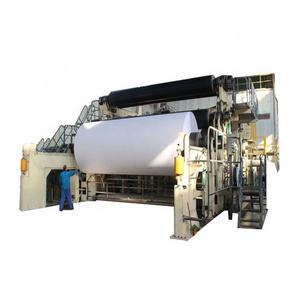

1575mm high speed jumbo roll toilet . tissue paper machine

1575 type single cylinder single dryer output 4-5 tons per day high quality toilet.tisue paper machine

| Main Parameters | |||

| Raw material | waste paper,pure pulp | ||

| Product | daily tissue,toilet paper | ||

| Paper grammage | 13-40gsm | ||

| Net paper width | 1575mm | ||

| Output per day | 2-3tons | ||

| Design speed | 120m/min | ||

| Working speed | 90-100m/min | ||

| Gauge | 2400 mm | ||

| Pressure mode | pneumatic pressure | ||

| Transmission mode | sectional drive, VVVF | ||

| Control mode | digital control system | ||

| Pulping Department (including matched motors) | |||

| Item | Qty | Power (KW) | |

| 1 | 5M3 high consistency hydrabrusher | 1 | 55 |

| 2 | 1.8M2 High frequency vibrating sreen | 1 | 7.5 |

| 3 | φ380 double disc refiner | 2 | 37 |

| 4 | 0.5M2 centrifugal screen | 1 | 22 |

| 5 | 606 low consistency desander | 12 | |

| 6 | φ700 prusher | 4 | 11 |

| 7 | φ8inch pulp pump | 2 | 18.5 |

| 8 | φ6inch pulp pump | 6 | 11 |

| 9 | φ6inch white water pump | 2 | 11 |

| 10 | two-phase flow pump-150 | 1 | |

| 11 | bleacher( screw thruster) | 2 | 11/5.5 |

| 12 | ZBK15 Roots vocuum pump | 1 |

15 |

| The host deparment | ||||||

| Item | Qty | Specifications | Material | |||

| 3 | cylinder mould + mould former | 1 | φ1500 x 2350mm |

stainless steel,

HT250 iron cast |

||

| 4 | couch roll | 1 | φ400 x 2350mm | seamless steel tube | ||

| 5 | wind pressure cylinder case | 1 | matched | high density polyethylene plate | ||

| 6 | guide roll | matched | φ159 x 2350mm | seamless steel tube | ||

| 7 | expander roll | matched | φ173 x 2350mm | seamless steel tube | ||

| 8 | high pressure spray pipe | 2 | matched | stainless steel | ||

| 9 | drying cylinder(dryer can) | 1 | φ2500 x 2350mm | HT250 iron cast | ||

| 10 | cradle roll | 1 | φ500 x 2350mm | HT250 iron cast | ||

| 11 | breathing type gas hood | 1 | matched | aluminium plate | ||

| 12 | vacuum suction box | 4 | matched | PVC + iron cast | ||

| 13 | winder cold cylinder | 1 | φ800 x 2350mm | HT250 iron cast | ||

| 14 | pneumatic scraper | 2 | steel | |||

| 15 | workbench | 1 | matched | HT250 iron cast | ||

| 16 | frequency control cabinet | 1 | matched | Q235 steel plate | ||

| 17 | air pump cabinet | 1 | matched | Q235 steel plate | ||

Partial products are packed by straw ropes, polybag/foam plastic and plywood materials, valuable parts are packed by wood board or wooden box.

Partial accessories are unpacked cargo in pieces.

1.Delivery Time:

20-120 days (base on actural production plan)after receipt of 30% deposit.

2.Payment Term:

30% T/T deposit, 70% T/T before loading to the container.

3. Quality Standard:

According to China Industry Standards and agreement of both parties.

4. The Warranty Period and Terms for quallity, repair, replacement:

a. 12 months from the date of successful running test,base on the line installed by the seller's engineer.

b. 13 months from the date of goods arrive at the destination port of the buyer, base on the line installed by the local engineer of the buyer.

c. Rubber-faced products is 6 months.

5.Inspection and cost:

The buyer come to China(supplier's workshop) f or inspection according to the drawing and official offer. I f the buyer need SGS or CIQ Certificates, the seller is not responsible for the inspection cost.

6. The transportation:

The seller is responsible for the packaging of the entire equipments, and loading all equipments into the container.

7.The Installation, trial production and training:

Installing time 60-120days, engineers are available to overseas for installation

and trial production and the training of the machine, and produce qualified products in accordance with contract requirements.

The buyer pays the salary, visa fee, come and back air fare, room and board of the engineer.

8.Repairing service and the relevent cost:

The seller will arrange the repairman to overseas or adopt other solving ways

within 20 days after receipt of the machine fault notice and good understading/communication for both parties. The relevent cost be negociated by both parties base on the actural situation.

9. Accessories:

The offer is excluding pipes and valves for water and slurry transporting,

the electric wire, the cement/brick/sand for paper slurry chest, other installing tool of installing.

1.Pre-sales Service

Proposing the most suitable scheme and equipment for our clients.

Designing and fabricating targeted products according to the special requirements of clients.

Training periodically high qualified service technician.

2.After-sales Service

Assisting our clients for foundation construction of equipment.

Dispatching engineers to install and debug equipment.

Training the first-line operators on site.

Regularly visit clients to solve production problems.