- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

JM23

-

Brand Name:

-

Jucos

-

Product name:

-

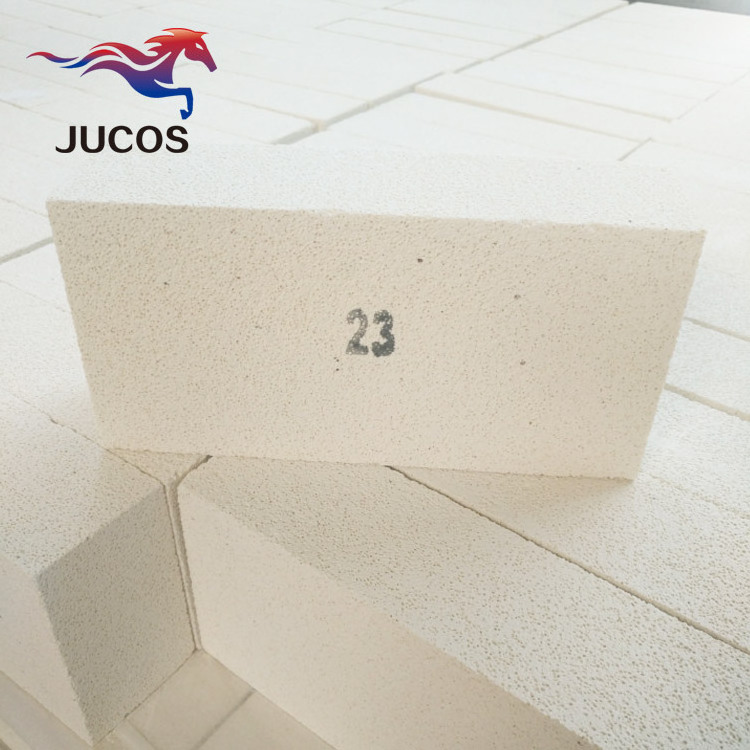

Jm23 Mullite Insulation Brick

-

CLASSIFICATION TEMP:

-

1300℃

-

Bulk density(g/cm3):

-

0.6G/CM3

-

CRUSHING STRENGTH:

-

1.2MPA

-

MODULUS OF RUPTURE:

-

1.0MPA

-

PERMANENT LINEAR CHANGE:

-

0.6

-

THERMAL EXPANSION:

-

0.5

-

AL2O3:

-

40%

-

FE2O3:

-

1.0%

-

MODEL NUMBER:

-

JM23

Quick Details

-

SiO2 Content (%):

-

International Standard

-

Al2O3 Content (%):

-

40%

-

MgO Content (%):

-

0.18%

-

CaO Content (%):

-

0.01

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

JM23

-

Brand Name:

-

Jucos

-

Product name:

-

Jm23 Mullite Insulation Brick

-

CLASSIFICATION TEMP:

-

1300℃

-

Bulk density(g/cm3):

-

0.6G/CM3

-

CRUSHING STRENGTH:

-

1.2MPA

-

MODULUS OF RUPTURE:

-

1.0MPA

-

PERMANENT LINEAR CHANGE:

-

0.6

-

THERMAL EXPANSION:

-

0.5

-

AL2O3:

-

40%

-

FE2O3:

-

1.0%

-

MODEL NUMBER:

-

JM23

Description Of Product

The bulk density of lightweight heat-insulating brick is 0.60~1.25g/cm3. Working temperatures range from 900℃ to 1600℃ . Each grade of products has unique design to meet different thermal, physical and chemical demands.Jucos series lightweight heat-insulating bricks are made from good quality and super-pure raw materials, with strictly classified fillings according to their grades. .Each face of the brick is machined grinding to the required accurate size.this material profitable by lessening fuel costs, construction costs and reducing the amount of time spent in the high temp furnace.

Features Of Product

Lower thermal conductivity

Lower bulk density

Light weight character

Lower creep rate in high temp

Good thermal shock resistance performance

Higher temperate resistant with good refractoriness

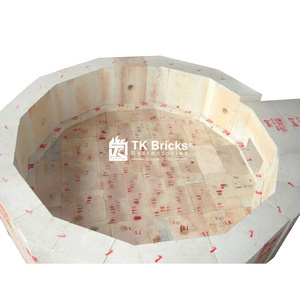

Applications Of Product

The refractory linings of hot surfaces or backing heat-insulating layers of other refractory materials. The refractory linings or heat-insulating materials of the industrial furnaces in the petroleum or chemical industries , such as , ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shuttle kilns, etc.

Specifications Of Product

Alumina contents range from 40% to 80%

Widely used throughout metallurgical industry

Physical And Chemical Indicators Of Product

|

Brand

Properties |

|

JM-23

|

JM -26

|

JM -28

|

JM -30

|

JM -32

|

|||||

|

Classification temperature (℃)

|

|

1300

|

1400

|

1500

|

1550

|

1600

|

|||||

|

Bulk Density (g/cm3)

|

|

0.6

|

0.8

|

0.9

|

1.0

|

1.1

|

|||||

|

Cold Crushing Strength (MPa)

|

|

1.2

|

1.8

|

2.5

|

3.3

|

3.5

|

|||||

|

Modulus of rupture (MPa)

|

|

1.0

|

1.7

|

2.3

|

3.1

|

3.2

|

|||||

|

(CT℃X24h) Permanent Linear Change (%)

|

|

0.6

|

0.6

|

0.8

|

0.9

|

1.01

|

|||||

|

@ 1,100℃ Thermal Linear Expansion(%)

|

|

0.50

|

0.52

|

0.52

|

0.53

|

0.7

|

|||||

|

Thermal conductivity (W/m.k)

|

350℃

|

0.18

|

0.27

|

0.32

|

0.38

|

0.49

|

|||||

|

|

400℃

|

0.20

|

0.29

|

0.34

|

0.40

|

0.5

|

|||||

|

|

600℃

|

0.24

|

0.32

|

0.36

|

0.42

|

0.51

|

|||||

|

(%) Chemical Analysis

|

Al2O3

|

40

|

56

|

67

|

73

|

77

|

|||||

|

|

Fe2O3

|

1.0

|

0.8

|

0.7

|

0.7

|

0.5

|

|||||

|

Main Applications

|

|

Ceramic Roller kiln reheating

Reheating Furnace Blast Furnace Petrochemical Furnace General Industrial Furnace etc. |

|

|

|

|

|||||

|

Brand

|

B-1

|

B-2

|

B-3

|

B-4

|

B-5

|

B-7

|

C-1

|

C-2

|

C-3

|

||||||||

|

Properties

|

|

|

|

|

|

|

|

|

|

||||||||

|

Reheating Shrinkage Temp (℃)

|

900

|

1,000

|

1,100

|

1,200

|

1,300

|

1,500

|

1,300

|

1,400

|

1,500

|

||||||||

|

Bulk Density (g/cm3)

|

0.70≥

|

0.70≥

|

0.75≥

|

0.80≥

|

0.80≥

|

1.00≥

|

1.10≥

|

1.20≥

|

1.25≥

|

||||||||

|

(kg/cm2)Cold Crushing Strength

|

25≤

|

25≤

|

25≤

|

25≤

|

25≤

|

30≤

|

50≤

|

70≤

|

100≤

|

||||||||

|

(W/m.k) at 350℃ Thermal conductivity

|

0.17≥

|

0.18≥

|

0.20≥

|

0.22≥

|

0.23≥

|

0.31≥

|

0.30≥

|

0.38≥

|

0.45≥

|

||||||||

|

Main Applications

|

Ceramic Roller kiln reheating

|

|

|

|

|

|

|

|

|

||||||||

|

|

Reheating Furnace

|

|

|

|

|

|

|

|

|

||||||||

|

|

Blast Furnace

|

|

|

|

|

|

|

|

|

||||||||

|

|

Petrochemical Furnace

|

|

|

|

|

|

|

|

|

||||||||

|

|

General Industrial Furnace etc.

|

|

|

|

|

|

|

|

|

||||||||

Pictures Of Product

Customer Reviews

JUCOS providing high grade refractory brick and insulation thermal ceramic fiber products to globe industrial high temperature furnace. Focus on refractory material selection,technical solutions,supplying,repairing,construction.China leading refractory supplier with competitive price and reliable quality.

Q1 : How can you control your quality?

A1 : For each production processing, JUCOS have complete QC system for the chemical

composition and Physical properties. After production, all the goods will be tested, and

the quality certificate will be shipped along with goods.

Q2: Are you a manufacture or trader?

A2: We are truly a manufacturer, we not only can provide the high quality products with the

best price, but also can offer the best pre-sale service and after-service .

Q3 : Do you provide free samples?

A3 : Of course, free samples are available.

Q4 : What is your lead time?

A4 : It usually needs about 15- 20 days after receiving the PO.

Q5 : Can we visit your company?

A5 : Yes, for sure, you are welcome to visit JUCOS company and our products.

Also, we can talk more about the technique details if you need.

Q6 : What is the warranty of your products?

A6 : Our products have at least 1 year warranty, if any quality problems,

we will take responsibility of the cost of the shipment and the replacement.

Q7: What's the MOQ of trial order?

A7 : No limit, we can offer the best suggestions and solutions according to your condition.

Q8: Why choose us?

A8: We had been in this line for more than 25 years , we can not only provide you high

quality products with competitive price, but also we can supply good technique service

which can help you solve problems.

Q9 : What standards do you have?

A9 : Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc.

The third party testing is all available for us.

A1 : For each production processing, JUCOS have complete QC system for the chemical

composition and Physical properties. After production, all the goods will be tested, and

the quality certificate will be shipped along with goods.

Q2: Are you a manufacture or trader?

A2: We are truly a manufacturer, we not only can provide the high quality products with the

best price, but also can offer the best pre-sale service and after-service .

Q3 : Do you provide free samples?

A3 : Of course, free samples are available.

Q4 : What is your lead time?

A4 : It usually needs about 15- 20 days after receiving the PO.

Q5 : Can we visit your company?

A5 : Yes, for sure, you are welcome to visit JUCOS company and our products.

Also, we can talk more about the technique details if you need.

Q6 : What is the warranty of your products?

A6 : Our products have at least 1 year warranty, if any quality problems,

we will take responsibility of the cost of the shipment and the replacement.

Q7: What's the MOQ of trial order?

A7 : No limit, we can offer the best suggestions and solutions according to your condition.

Q8: Why choose us?

A8: We had been in this line for more than 25 years , we can not only provide you high

quality products with competitive price, but also we can supply good technique service

which can help you solve problems.

Q9 : What standards do you have?

A9 : Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc.

The third party testing is all available for us.

Connact Us

Hot Searches