- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XINYUAN

-

Model Number:

-

N35-N52 (M.H.SH.UH.EH.AH)

-

Certification:

-

ISO9001:2008

-

Size:

-

Accept customized

-

Delivery time:

-

7-25days

-

Working Temperature:

-

80-220 degree

Quick Details

-

Tolerance:

-

±10%

-

Grade:

-

neodymium magnet, N35-N52 (M.H.SH.UH.EH.AH)

-

Place of Origin:

-

Guangdong, China, Guangdong, China

-

Brand Name:

-

XINYUAN

-

Model Number:

-

N35-N52 (M.H.SH.UH.EH.AH)

-

Certification:

-

ISO9001:2008

-

Size:

-

Accept customized

-

Delivery time:

-

7-25days

-

Working Temperature:

-

80-220 degree

Product Description

Over 11 Years Experience Neodymium Magnet Manufacturer

2 Years Verified Golden Supplier In Alibaba

100% Satisfaction Guaranteed On Quality

Samples and Trial Orders Are Most Welcome

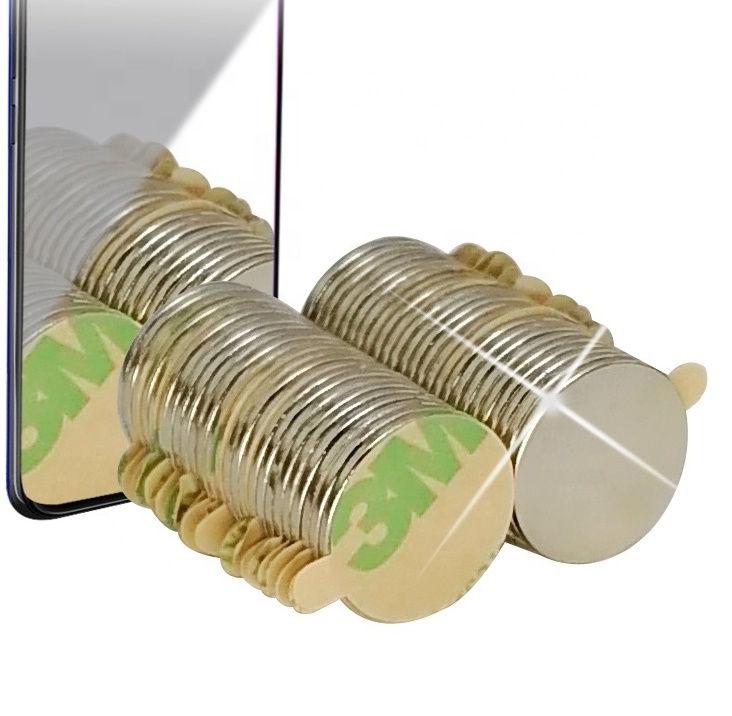

High Quality N50 Strong NdFeB Disc Magnets

|

Product Name

|

High Quality N50 Strong NdFeB Disc Magnets

|

|

|

|

|||

|

Material

|

Permanent Neodymium Magnet

|

|

|

|

|||

|

Demension

|

Customized size

|

|

|

|

|||

|

Coating

|

Nickel/Zinc

|

|

|

|

|||

|

Magnetization Direction

|

Thickness, Axially

|

|

|

|

|||

|

Delivery time

|

3-10 days for sample, 10-15days for production, According to the stocks

|

|

|

|

|||

|

Capicity

|

500 Ton each one month

|

|

|

|

|||

|

Inner packaging

|

Put the magnet into the paper box separetely or as your request

|

|

|

|

|||

|

outer packaging

|

35*25*20cm

|

|

|

|

|||

|

Warning

|

1.Don't swallow, This product contains small magnet, Swallowed magnets can stick together across intestines,causing serious or fatal injury, Seek immedicate medical attention if magnets are swallowd or inhaled

2. Don't put them in nose or mouth which are so super strong, And must be kept far away from Children

|

|

|

|

|||

Sintered Nd-Fe-B Magnets

The third generation of rare earth permanent magnet NdFeB is the most powerful permanent magnet in modern magnets. It not only has the characteristics of high remanence, high coercivity, high magnetic energy product, high performance-to-price ratio, but also is easy to be processed into various sizes. Now it has been widely applied in various fields. Especially suitable for the development of high-performance, miniaturized, lightweight alternative products.

We accept customized services:

1) Shape and Dimension Requirements 2) Material and coating requirements

3) Processing according to design drawings

4)Requirements for Magnetization Direction

5) Magnet Grade Requirements

6) Surface treatment requirements (plating requirements)

Product flow chart &Magnetization direction& Coating

|

Plating Type

|

Overall Thickness

|

Salt Spray Test

|

Pressure Cooker Test

|

pass

|

|

NiCuNi (Nickel Copper Nickel)

|

15-21 μm

|

24 hours

|

48 hours

|

|

|

NiCu + Black Nickel

|

15-21 μm

|

24 hours

|

48 hours

|

|

|

NiCuNi + Epoxy

|

20-28 μm

|

48 hours

|

72 hours

|

|

|

NiCuNi + Gold

|

16-23 μm

|

36 hours

|

72 hours

|

|

|

NiCuNi + Sliver

|

16-23 μm

|

24 hours

|

48 hours

|

|

|

Zinc

|

7 -15 μm

|

12 hours

|

24 hours

|

|

Magnetization&Surface plating

Recommend Products

Hot Searches