- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CNP

-

Dimension(L*W*H):

-

300mm dia X 1500mm

-

Weight:

-

2500 - 10373KGS, 35.4 - 600KGS

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts

-

Air volume:

-

1500 - 240000 m3 / h

-

Pressure:

-

420 - 1400 pa

-

Wind inlet speed:

-

12 - 20 m / s

-

High:

-

1360 - 4545mm

-

Wind out pipe dia:

-

180 - 630 mm dia.

-

Discharger flange center distance:

-

210 -676 mm dia.

-

Particle concentration:

-

2 - 400g /m3

-

Product describe:

-

Mine dust collection and secondary dust filtering

-

Certification:

-

CE ISO certificate

Quick Details

-

Core Components:

-

none

-

Minimum Particle Size:

-

10 micron

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

CNP

-

Dimension(L*W*H):

-

300mm dia X 1500mm

-

Weight:

-

2500 - 10373KGS, 35.4 - 600KGS

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts

-

Air volume:

-

1500 - 240000 m3 / h

-

Pressure:

-

420 - 1400 pa

-

Wind inlet speed:

-

12 - 20 m / s

-

High:

-

1360 - 4545mm

-

Wind out pipe dia:

-

180 - 630 mm dia.

-

Discharger flange center distance:

-

210 -676 mm dia.

-

Particle concentration:

-

2 - 400g /m3

-

Product describe:

-

Mine dust collection and secondary dust filtering

-

Certification:

-

CE ISO certificate

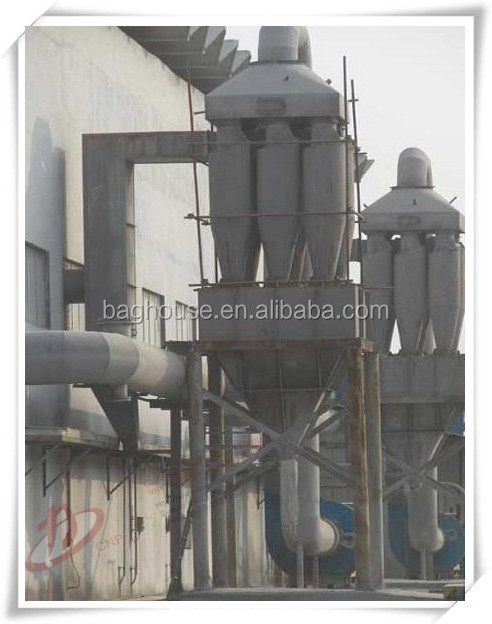

Cyclone collector Introduction

Cyclone Collector are often employed as an Initial Stage Collector to lighten heavy dusts loads before being sent to a Primary Stage Fabric Collector. By removing coarse particles from the gas stream, and allowing later stage Fabric Collectors to solely remove finer particles, these collectors increase the efficiency and service life of Fabric Collectors (Baghouses) and their Filters. Thus protecting your larger and most costly investment from unnecessary wear and tear.

It often named after the cyclone weather phenomenon, are large funnel shaped sheet metal tubes connected to ducts often used in woodshops, machine shops, manufacturing plants, and powder processing plants. Dust and debris are sucked in at the top. Air containing fine dust blows out of the other side of the top, while chips and large dust particles fall out of the bottom into a drum or bin. Dusty exhaust air is either blown outside or filtered again using media filtration.

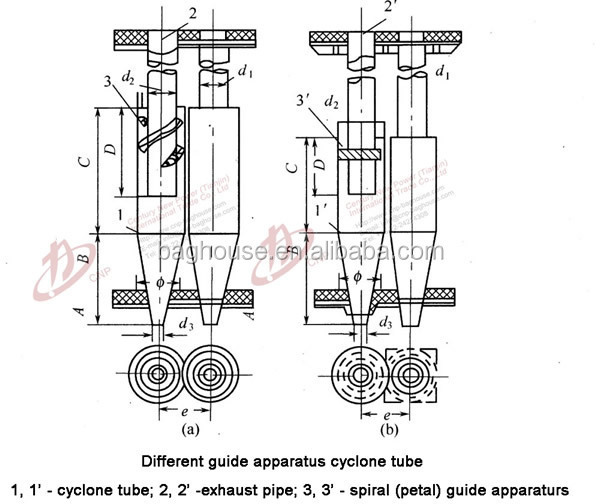

Multi-tube cyclone dust collector introduction

Vertical multi-tube cyclone of multiple cyclone, the cyclone tube inlet has the guide device. There are three kinds of 100 mm, 150 mm and 100 mm cyclone tube. The commonly used is 250 mm one. Guide apparatus has the spiral and petals two types. Spiral guide blade slices with low pressure loss, not easy to plug, and dust removal efficiency is lower. Although petals guide vane has higher dust removal efficiency, but easy to block. Guide vane outlet Angle is commonly 25 ° and 30 °

Working principle

As the dirty air enters the cyclone dust collector, it is forced into a swirling movement. This results in a centrifugal force acting on the dust particles suspended in the air stream. The particles, denser than the air, are forced to move outwards, towards the cyclone dust collector wall. They then fall downwards, towards the dust exit. The clean air is eventually directed towards the centre of the cyclone and leaves through the gas exit.

Cyclone dust collector efficiency is a function of the physical parameters of the particles and the design parameters of the unit. Cyclone efficiency increases with:

- Coarse particle size distribution

- Higher products specific gravity

- Lower gas density

- Smaller outlet diameter. An increase in pressure drop also results.

Characteristic

The Cyclone dust collector hasn't any moving parts. It's conenient for manufacture and management. With the same air volume, The cyclone collector is more smaller size, and the price is more cheaper. As the second dedusting and matched with bag filter, it can be installed vertically, also can be installed in a horizontal. So, it is easy to install and applicate. The cyclone collector efficiency of resistance is not affected for many sets of cylcone dollector in multiple using when processing the large dust gas air volume.

STRUCTURE COMPOSITION

Multi tube cyclone tube size:

Multi tube cyclone dust collector size :

XLP type cyclone dust collector main performance:

********************

Please click the following product name to view more product details:

SINGLE BAG FILTER ROUND PULSE FILTER CENTRIFUGAL FAN REVERSE BLOW FILTER DUST COLLECTOR

FILTER BAG / FILTER CAGE SCREW CONVEYOR AIRSLIDE FABRIC / HOSE PULSE VALVE UNLOADER FILTER FELT

********************

We provide all kinds of standard export packing for cargo protection. The bag filter will be fixed on the container. The filter bag and cages will be fixed in corrugated box and steel framed structure.

1. Enquiries quickly reply within 24 hours.

2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved.

3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design.

4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle.

5. The bag filter equipment over 20 years working life.

6. Associated with equipment spare parts, ensure the replacement parts within 20 years.

7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production.

8. Ensure easy operation and absolutely no worries about future