- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

365 days

-

Brand Name:

-

DESHI

-

Model Number:

-

8X6E-HS

-

Place of Origin:

-

Hebei, China

-

Horsepower:

-

100

-

Cable Length:

-

Costomized

-

Outlet Size:

-

150 mm

-

Power:

-

max 120kw

-

motor:

-

Electric motor

-

Seal type:

-

Gland or Expeller

-

Wear Parts:

-

High Chrome alloy

-

Gland:

-

SS304

-

Pump Casing:

-

Ductile Iron

-

Bearings:

-

China brand

-

Packing:

-

Aramid fiber

-

Color:

-

Blue

-

Packaging:

-

Wooden case

-

Rubber Wear Parts:

-

Available

Quick Details

-

Application:

-

Industrial Utilities, Irrigation and Agriculture, Machining, Marine, Mining industry, Washing and Cleaning, Wastewater Transport and Flood Control, wastewater treatment, Water Treatment Solutions

-

Pressure:

-

High Pressure

-

Voltage:

-

380~440 V

-

Warranty:

-

365 days

-

Brand Name:

-

DESHI

-

Model Number:

-

8X6E-HS

-

Place of Origin:

-

Hebei, China

-

Horsepower:

-

100

-

Cable Length:

-

Costomized

-

Outlet Size:

-

150 mm

-

Power:

-

max 120kw

-

motor:

-

Electric motor

-

Seal type:

-

Gland or Expeller

-

Wear Parts:

-

High Chrome alloy

-

Gland:

-

SS304

-

Pump Casing:

-

Ductile Iron

-

Bearings:

-

China brand

-

Packing:

-

Aramid fiber

-

Color:

-

Blue

-

Packaging:

-

Wooden case

-

Rubber Wear Parts:

-

Available

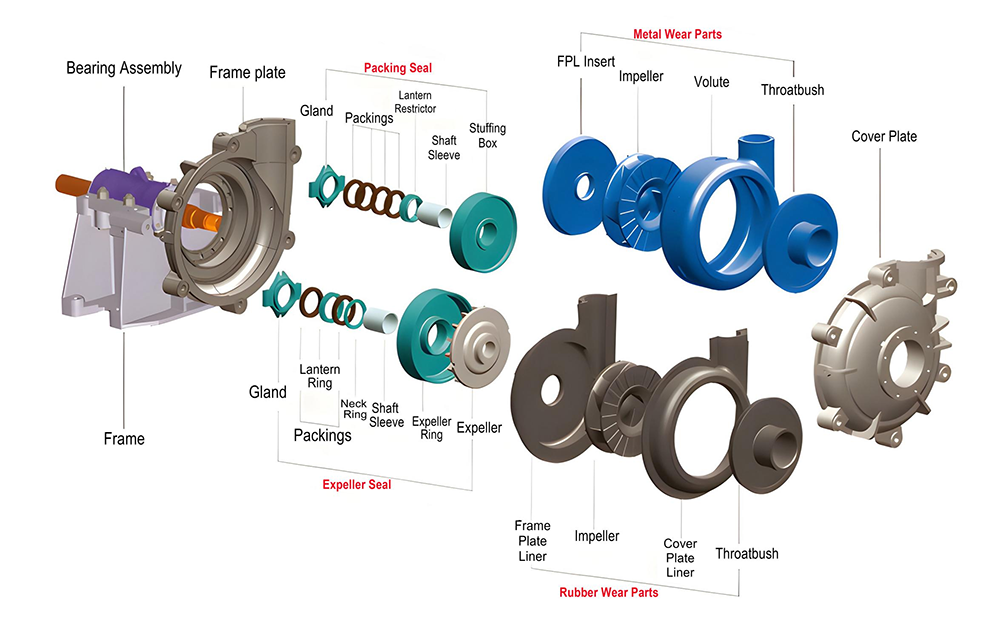

HS type horizontal heavy duty rubber chrome sand pump slurry pump

Introduction:

HS

series

horizontal

slurry pump is designed for the continuous pumping of high abrasive, high density slurries with minimal maintenance requirements.

The wearing parts are made of

superior anti-wear high chrome alloy or abrasion/corrosion resistant rubber

.

It will maintain high efficiency over the wear life of its components.

The metal wet parts and rubber ones can be interchangeable for handling different liquids or slurries .

Overview:

Discharge

Size: 1" to 22"

Flow Rate

: 3.6-5400 m3/h

Head: 6-125 m

Handing solids: 0-130mm

Slurry

Concentration: 0%-70%

Pump casings: Ductile Cast Iron

Impeller, liner, throatbush

:

high-

chrome alloy, Rubber, Polyurethane, Ceramic, Stainless steel etc

This centrifugal pumps are available with a variety of impellers and shaft seals to provide the perfect fit for a wide range of applications.

Typical Application:

|

• Mineral processing |

• Mining |

• Coal Washery |

• Cyclone feeds |

|

• Aggregate |

• Chemical slurr y |

• Tailing |

• Mill grinding |

|

• Ash handing |

• M etallurgy |

• Waste sludge |

• Coarse sand |

|

• Sand |

• Phosphoric acid |

• Dredging |

• Sewage |

|

• Quarry |

• Power Plant |

• Fertilizer |

• Tunnel |

|

• Iron ore sand |

• Copper Concentration |

• Gold mine |

• Molybdenum |

|

B entonite |

Construction |

Island Reclaiming |

Alumina Industry |

Design Features:

1. Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and front liner

and can be

removed completely;

2. Interchangeable anti-abrasive wet parts made of high-chrome alloys

and abrasion resistant polymer

3.

Casing halves of ductile iron with external reinforcing ribs provide high operating pressure capabilities

and an extra measure of safety.

4. The discharge branch can be oriented to any eight positions at the interval of 45 degrees;

5. Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD,

SCR control, etc;

6. The shaft seal uses the packing seal, expeller seal and mechanical seal

Wear Parts

Shaft Seal Arrangement:

Shaft Seal Arrangement:

Pump Model Brief Selection Chart

Horizontal Slurry Pumps Performance Parameters

Note:

1. “ M ” means high chrome alloy; “ RU ” means rubber(polymer)

2. Flow Rate range recommended : 50%Q ≤ Q ≤ 110%Q

Outline Dimensions

Please contact us for the detailed outline drawings if needed.

Motor Drive Type:

Assembly Workshop

Packaging & Shipping:

Applications Case:

Our main products:

Note: The displayed prices are for reference only, and the final price should be subject to mutual negotiation.

Welcome to contact us any time for more details.

Your inquiry or advice will get our prompt attention and response !