- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

KAIDA

-

Model Number:

-

HS-600 HS-601 HS606

-

Type:

-

Liquid Glue

-

Product name:

-

Concrete Hardener Sealer

-

Certificates::

-

ISO CE

-

Application:

-

terrazzo, mortar, all exposed concrete surface

-

Packaging:

-

25kg Plastic sealed bucket

-

Color:

-

Colorless and transparent

-

Keyword:

-

Concrete Floor Hardener

-

Shelf life:

-

6 Months

Quick Details

-

CAS No.:

-

98-67-9

-

Other Names:

-

Concrete Hardener Sealer

-

MF:

-

C8H12N2O2

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

KAIDA

-

Model Number:

-

HS-600 HS-601 HS606

-

Type:

-

Liquid Glue

-

Product name:

-

Concrete Hardener Sealer

-

Certificates::

-

ISO CE

-

Application:

-

terrazzo, mortar, all exposed concrete surface

-

Packaging:

-

25kg Plastic sealed bucket

-

Color:

-

Colorless and transparent

-

Keyword:

-

Concrete Floor Hardener

-

Shelf life:

-

6 Months

The two-component curing agent is a flooring material used for concrete curing. By chemically reacting with the active ingredients in the concrete, the concrete wear resistance. hardness. corrosion resistance. etc. are improved, and the service life of the concrete is prolonged.

PRODUCT FEATURES:

The HS-600 base compact curing agent is a colorless to yellowish translucent viscous liquid.

HS-601 hardening bright curing agent is a transparent liquid. KAIDA sealing curing agent is non-toxic, odorless. non-combustible. environmentally safe and meets VOC environmental protection requirements.

Performance comparison of KAIDA and other flooring materials:

| Epoxy floor | Wear-resistant floor | Terrazzo | KAIDA seal curing agent | ||

| Performance | Dustproof effect | Dust free | Reduce dust free | Reduce dust free | Dust free |

| Wear resistance | 2.3 | 4.6 | 3.3 | 6.2 | |

| Moh's hardness | 2-3 | 6-7 | 4 | 8-10 | |

| Anti-infiltration | 0Ml/H | 200Ml/H | 250Ml/H | 0.055Ml/H | |

| Anti-aging | 3-5years | 5-8years | 5-8years | More than 50 years | |

| Warranty | 1year | 3years | 3years | At least 20 years | |

| Construction features | Construction method | Multiple layers multiple times | Throwing machine | Water mill | Spray or roll |

| Duration | After the new floor is dried for 28 days, the construction is about 500M2 per day. | Simultaneously with concrete pouring, about 1000M2 per day | Long construction period, 30 days per 3000m2 | After maintenance with concrete | |

| About 2000M2 per day | |||||

| Maintenance period | One week | 14 days | 3 days | 3 hours after construction is completed | |

| 7 days can carry | |||||

| safety | Slightly toxic and irritating, construction requires fire protection | More dust, | Too many pollutants in construction, not environmentally friendly | Comply with all VOC rules | |

| Environmental protection | Not environmentally friendly | Construction personnel need to do protection | Non-toxic, non-combustible, environmentally friendly | ||

| basic requirements | Can only be used on new ground | no request | Both new and old floors are available | ||

| Otherwise easy to shell | Old ground cannot be used | No waterproof requirements | |||

Concrete seal curing agent can improve:

Comprehensive performance of concrete, stone, plaster, mortar, concrete and other products

Concrete surface hardness of 33.3% and density, thereby reducing damage to the ground by heavy machinery

Bending strength, tinting strength and bond strength of other materials

Concrete seal curing agent is resistant to:

Up to 98% water and water vapor pressure

Various chlorides, oil stains, gases, acids, solvents, bacteria, and UV rays on highways and at sea

Peeling, shrinking, spalling due to temperature difference

Concrete seal curing agent prevents:

Diffusion of various toxic gases

50% to 90% internal chloride

Reduces maintenance costs by contaminating rust and waterborne contaminants

Moss, moss and other organisms grow on the surface, eliminating the need for regular removal

Product Benefits

Prevent the penetration of moisture

Can penetrate up to 15mm

Prevent alkalizing and weathering

Prevent internal metal corrosion

Resistance to acid attack

Increase the R factor insulation factor

Enhanced weatherability

Prevent chloride attack

Prevent mold and fungus

Simple construction

Prevent paint from peeling off

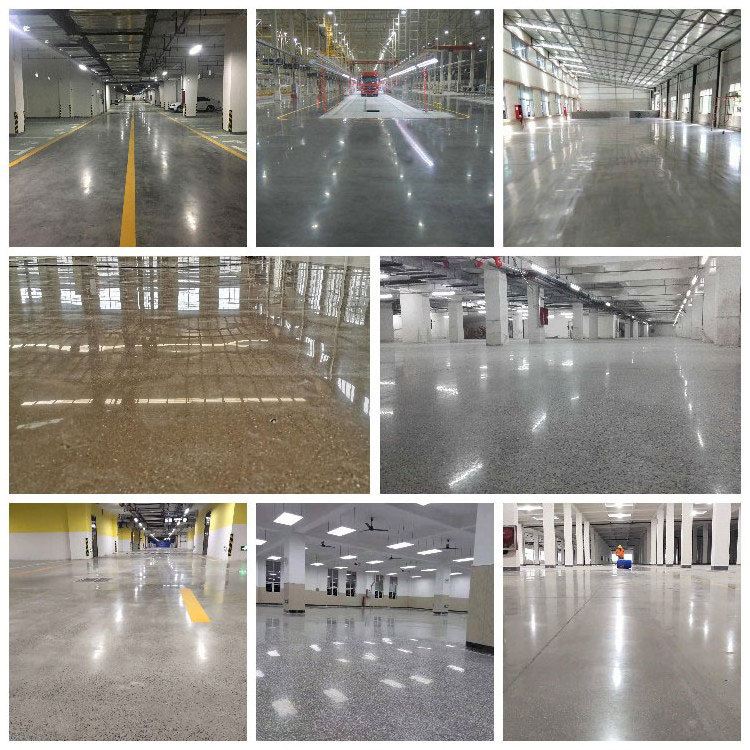

Construction Case:

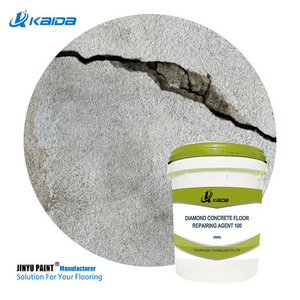

Why is it better to use two-part sealed Hardener?

1.If there is a small crack in the surface after 3-5 years, each material surface, and with the extension of time will become more and more obvious..

2. for the new ground, the relatively dense ground floor, can be preferred single group, simple and convenient construction, the ground beautiful. For the old cement ground loose ground, must choose the two sets of concrete seal curing agent, also may make the hard and beautiful ground.

The two-part concrete sealing agent (one group is alkaline, the other is acidic) can avoid the occurrence of cracks . Its service life can be really up to 20 years.

When is the sealing agent in general, what is it based on?

Based on the actual situation on the ground. It is polished before it is polished to 150 mesh or 300 eyes.

Before grinding, it is because the ground is loose and the hardness is raised.

General ground or better ground, before grinding to 300 mesh can be.

Is the curing agent required for the construction temperature?

The sealing agent construction principle is above 0 degrees, 50 degrees below construction is possible. The sealing agent can not be frozen, as if its frozen it cannot penetrate. High temperature will affect the curing time.

Q1, Are you manufacturer or trading factory?

A: In fact we are the factory more then 10 years, can supply all types of paint.

Q2, If the OEM is accepted?

A: Yes, OEM is welcome. We also can do your own logo and package.

Q3, If I do not know which paint to choose, what shall I do?

A: Please no need to worried about this, we have the professional engineer, colorist, and experienced sales, can give you the suggestion for paint and coating.

Q4, What’s are your payment term?

A: We can accept the TT, Western Uniono, LC, Credit card, and Alipay, and others please contact with us freely.

Q5, Can you accept to supply the free sample?

A: Yes, of course we are glad to supply the free sample, and you need in charge of the freight cost.

Q6, What's your products' advantages?

A. Good quality and competitive prices.

B. Strictly quality control when producing.

C. Professional team work, from design, development, producing,assemble,packing and shipping.

D. Experience for shipping the paint to different countries.

Q7, Can we visit your factory?

You are Warmly welcomed to visit our factory, it would be our great pleasure!