- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

3000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

12kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

suntec

-

Voltage:

-

380/440v

-

Dimension(L*W*H):

-

5200*3800*2000

-

Power (kW):

-

15

-

Weight (KG):

-

10000

-

working area:

-

2000*3000*1000mm

-

spindle:

-

Hitec spindle

-

5 AXIS head:

-

Italy brand

-

controller:

-

syntec TPA osai

-

Working table:

-

vacuum table

-

Software:

-

powermill mastercam UG

-

Transmission:

-

PMI 40 square guide

-

Driver:

-

yaskawa driver and motor

Quick Details

-

Working Table Size(mm):

-

2000*3000

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

3000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

12kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

suntec

-

Voltage:

-

380/440v

-

Dimension(L*W*H):

-

5200*3800*2000

-

Power (kW):

-

15

-

Weight (KG):

-

10000

-

working area:

-

2000*3000*1000mm

-

spindle:

-

Hitec spindle

-

5 AXIS head:

-

Italy brand

-

controller:

-

syntec TPA osai

-

Working table:

-

vacuum table

-

Software:

-

powermill mastercam UG

-

Transmission:

-

PMI 40 square guide

-

Driver:

-

yaskawa driver and motor

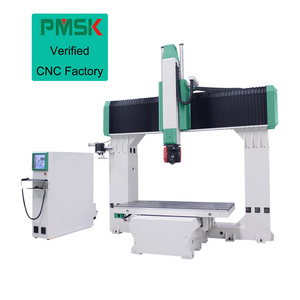

Suntec boat mold machine cnc router 5 axis eva foam making machine cnc milling machine 5 axis

Suntec 5 Axis CNC Machining – Common Uses

5-axis CNC machining can be used to produce parts utilized in plenty of different industries due to their efficiency and the ability to produce complex shapes. Here are a few examples of industries that most commonly take advantage of this technology:

Aerospace – this industry requires a very precise machine, as the shapes are very intricate and unique.

Medical – 5-axis CNC machining can help manufacturers of medical equipment in the production of devices, implants, as well as other pieces of equipment that need to be made with extra precision in order to meet healthcare standards which tend to be rigorous (rightfully so).

Military – another industry that uses 5-axis CNC machining to produce the needed parts. Some of the possible applications include submarine parts, high-performance engine parts, turbine and compressor blades, smart weapons, sensors, stealth applications, as well as, in some cases, nuclear weaponry.

Energy equipment – producing parts for energy equipment often requires using materials that are hard to work with. With 5-axis CNC machining, you can make the whole process easier and more efficient.

Suntec 5 axis details

1. suntec 5 axis XYZAC 5 axis XYZ 3 axis move A +_110 C axis +_245 degree rotary

which can mill trim cut carve engrave surface of working material such as composite materials sucha fiberglass carbon Eps foam styrofoam , plastic aluminum hard wood etc . suntec 5 axis can apply liquid rocket engine nozzle a space shuttle nose cone aircraft brake disc wood mold ,

car plane boat yacht mold parts cast dieing non-metal making mold etc .

2. suntec 5 axis all used Top-brand parts HSD spindle hitec spindle italy Demas 5 axis head ,hsd spindle TPA osai or syntec controller . japan yaskawa absolutely driver and motor helica 3M gear to make sure high precision 0.1mm can be use longlife and low cost low time to maintainance .

3. Suntec 5 axis all use heavy-thick steel welded some parts 12mm thick some even 20 mm welded gantry lengs all heattreatment to delete itself rigidity to make sure longlife use no deformed ,all strucutre by 5 cnc center to mill one legs square guide need 3-5 days by 5 sides cnc center to mill low speed high torque to make sure high precision.

4. Suntec 5 axis working table cast iron table one table from 5-20t according your working material to decide which also can make sure high precision .

5. Suntec 5 axis cnc install use laser to adjust XYZAX callbrate alignment to make sure high

precision .

|

Number |

Description |

Parameter |

|

1 |

X,Y,Z Working Area |

2000*3000*1000mm |

|

2 |

Table Size |

3300×5700mm |

|

3 |

X,Y,Z Traveling Positioning Accuracy |

±0.01/1000mm |

|

4 |

A axis |

A ±110 degree |

|

5 |

C rotary |

C± 245 degree |

|

5 |

Table Surface |

moveable table |

|

6 |

Frame |

Big Steel Tube Structure with heat treatment |

|

7 |

X, Y Structure |

Rack and Pinion Drive, Hiwin Rail Linear Bearings |

|

8 |

Z Structure |

Hiwin Rail Linear Bearings and TBI Ball Screw |

|

9 |

Max. Power Consumption |

(Without Spindle) 12 Kw |

|

10 |

Max. Rapid Travel Rate |

40000mm/min |

|

11 |

Max. Working Speed |

30000mm/min |

|

12 |

Spindle Power |

12kw |

|

13 |

Spindle Speed |

0-24000RPM |

|

14 |

Drive Motors |

5000W Yaskawa Motors |

|

15 |

Working Voltage |

AC380V/50/60Hz,3PH (Option: 220V)) |

|

16 |

Command Language |

G Code |

|

17 |

Operating System |

Syntec Control System/TPA /osai |

|

18 |

Computer Interface |

USB |

|

19 |

Flash Memory |

512M |

|

20 |

Collet |

HSK-F63 |

|

21 |

X,Y Resolution |

<0.01mm |

|

22 |

Software Compatibility |

powermill UG software |

|

23 |

Running Environment Temperature |

0 - 45 Centigrade |

|

24 |

Relative Humidity |

30% - 75% |

|

25 |

Packing Size |

5500X2100X2300mm |

|

26 |

N.W. |

6000KG |

|

27 |

G.W. |

8000kG |

|

28 |

Optional Parts |

Dust Collector/ Dust Hoods for three Axis |

|

Vacuum Pump |

||

|

Rotary System |

||

|

Mist-cooling System |

||

|

Delta/ Panasonic Servo Motors |

||

|

Colombo Spindle |

||

|

Schmalz PTP table |

Suntec 5 axis production details

suntec structure legs after heattreatment then sanding blast to release itself rigidity to make sure

longlife use no deformed . one legs 6000kgs .enough to bear z axis with 5 axis head

Much Heavier Cast iron table to make sure high precision it can be 0.1mm

Enforced fourside steel inside all struture legs gantry to make sure high force to make sure high precision .

Heat treatment gantry in fire 3 days to delete itself rigidity .

XYZ 45 square guide with steel plate to make sure it same level to make sure high precision

Syntec controll with RTCP (Rotated Tool Center Point), also known as TCPM,TCPC or RPCP, refers to the function maintaining rotary axes at constant angle between tool and surface to be machined. In 5-axis machining, the additional motion of the tool point is generated due to the rotary motion when following the tool point path and the angle between the tool and the workpiece. The control point of CNC system is often not coincident with the tool point, so the CNC system should automatically correct the control point to ensure that the tool point moves according to the given trajectory.

Suntec airplug with control box easy to loading

Suntec 5 axis cnc install air condioner for working at good enviroment to make sure all parts longlife use.

Water chiller to cooling spindle voltage transformer to make sure voltage stable .

10kw Htec spindle it fit for fiberglass carbon plastic no metal working and no thick material . spindle power according your material to choose .

japan yasawa aboslutely driver high powerful high speed, high precision. Motor’s max. torque can reach 350% which may shorten speed up and slow down time. The servo motor can response instantly. High resolution makes high Precision position and high precision procession.

Suntec 5 axis atc tools HSKF-63 holder 8 piece one is with saw other can with ballcutter all according your working path to choose tools .

laser test precision before delivery all make sure 0.05-0.1mm

Renishaw for optional .

Packing suntec 5 axis cnc router

Suntec working sample in customer workshop

Suntec 5 axis cnc ST-2030 in France customer workshop for composite material boats making

Suntec 5 axis cnc in Germany customer workshop for aluminum mold making which use high torque BT50 spindle low speed high torque

Suntec 5 axis in USA CUSTOMER WORKSHOP FOR HARD WOOD PATTERN MAKING

SUNTEC 5 AXIS CNC FOR FOAM MOLD MAKING

SUNTEC 5 AXIS IN LATVIA CUSTOMER FOR BATHROOM PARTS MAKING

SUNTEC 5 AXIS CNC FOR FURNITURE BENT LEGS MAKING IN PERU CUSTOMER WORKSHOP

Suntec 5 axis cnc router ST-1212 make Germany sample

Suntec 5 axis cnc in USA workshop for plane parts making

Suntec 5 axis feedback by customer

suntec 5 axis cnc application

plastics by vacuum forming

Aeroplane new energy parts making

carbon material

Foam mold

composite material mold making milling trimming

Transfer of molds from MDF to fiberglass

The mold from MDF

thermoplastics

Glass and carbon fiber reinforced duroplastics

Molded parts made of GMT and SMC

Molded parts made of foam, leather and a carrier part using the sandwich technique

wood paneling

plywood moldings

Honeycomb lightweight materials

blow molded parts

Model construction foams in tool and model construction