- Product Details

- {{item.text}}

Quick Details

-

Compress Strength:

-

≥150 pa

-

THERMAL CONDUCTIVITY:

-

≤0.03 W /m .k

-

Water Absorption:

-

≤1.5 %

-

Color:

-

blue is common

-

Width:

-

600mm

-

Lenght:

-

1200mm

-

Apparent Density:

-

35~55kg/m3

Quick Details

-

Product name:

-

XPS Extruded Polystyrene Foam Board

-

Thickness:

-

30mm-300mm

-

Material:

-

Polystyrene resin

-

Compress Strength:

-

≥150 pa

-

THERMAL CONDUCTIVITY:

-

≤0.03 W /m .k

-

Water Absorption:

-

≤1.5 %

-

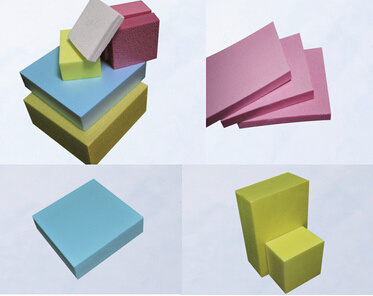

Color:

-

blue is common

-

Width:

-

600mm

-

Lenght:

-

1200mm

-

Apparent Density:

-

35~55kg/m3

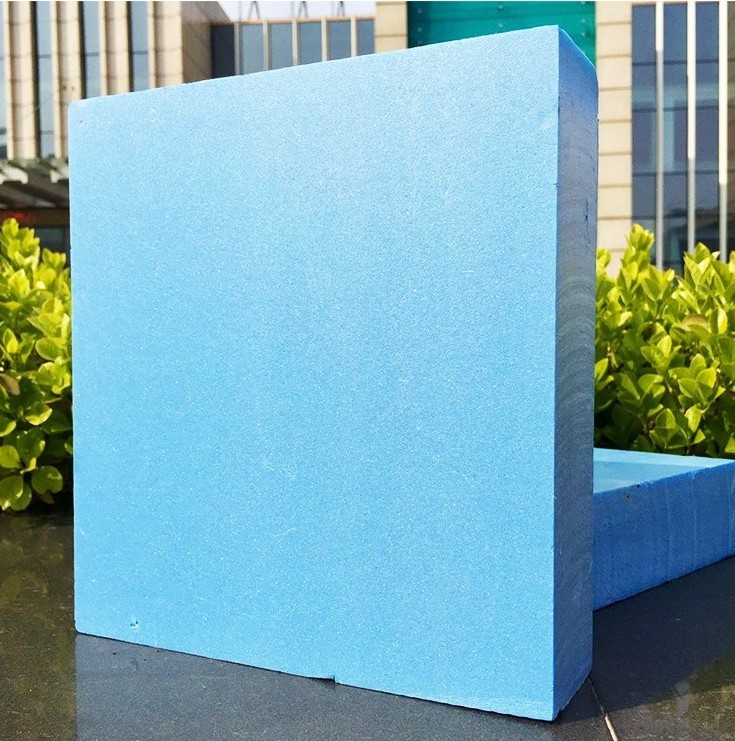

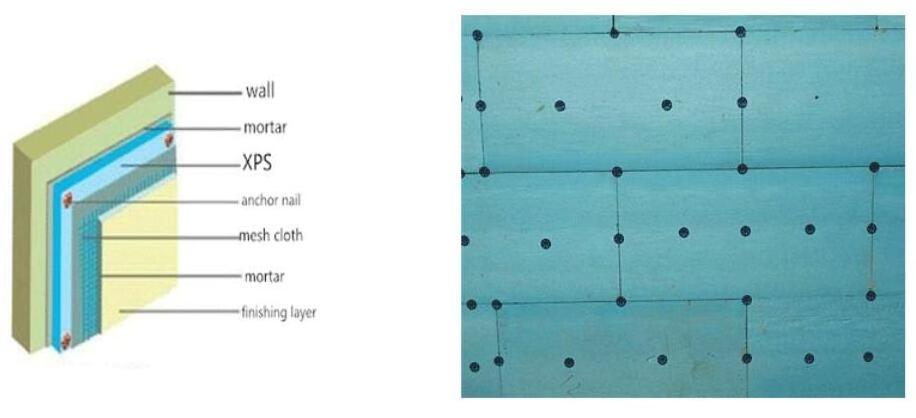

XPS extruded thermal insulation board external wall roof heat insulation sound insulation board

The extruded polyphenylene insulation board (xps) is a rigid sheet which is continuously extruded and foamed by a special process using polystyrene resin as a raw material. The inside is an independent closed bubble structure, which is a kind of high pressure resistance. , non-absorbent, moisture-proof, airtight, lightweight, corrosion-resistant, long service life, low thermal conductivity and other environmentally friendly insulation materials.

XPS extruded polyphenylene insulation board Technical Data

|

Physical and mechanical properties of (GB / T10801.2-2002) ( GB/T10801.2-2002 ) |

|||

|

item |

unit |

XPS150 | |

|

GB standard |

|||

|

Compression strength |

Kpa |

≥ 150 |

256 |

|

Water absorption (immersion 96h) |

% |

≤ 1.5 |

0.4 |

|

Moisture absorption coefficient |

ng/ ( m · s · pa ) |

≤ 3.5 |

1.9 |

|

Thermal resistance (thickness 25mm, the average temperature of 10 ℃ ) |

( m3 · k ) /W |

≥ 0.89 |

0.92 |

|

Thermal resistance (25mm thickness, the average temperature of 25 ℃ ) |

( m3 · k ) /W |

≥ 0.83 |

0.86 |

|

Thermal conductivity (average temperature 10 ℃ ) |

W/ ( m · k ) |

≤ 0.028 |

0.026 |

|

Thermal conductivity (average temperature 25 ℃ ) |

W/ ( m · k ) |

≤ 0.030 |

0.028 |

|

Dimensional stability |

% |

≤ 2.0 |

1.0 |

|

fireproofing grade |

level |

B2 lecel |

B1 or B2 level |

|

Oxygen Index |

% |

≥ 30 |

31 |

XPS wall and floor heat insulation board advantage

1. Excellent thermal insulation performance: very low thermal conductivity ,used as the insulation structure of the fence structure ,it can be the most economical (with the minimum thickness) materials which can meet the building insulation requirements

2. Carbon dioxide foaming process: The cutting-edge CO2 foaming process replaces the traditional Freon (CFC and HCFC) gas, protects the ozone layer, it is more environmentally friendly and energy-saving, non-radioactive or volatile, formaldehyde-free and safe for both indoor and outdoor use.

3. High compressive strength: Extruded board can provide perfect compression capacity and impact resistance, compressive strength is up to 800KPa. It is more than just a light weight insulating material, its intrinsic mechanical strength enables it to withstand higher load pressure on the ground and underground side walls , provide the solution of thermal insulation and structure as one

4 fire resistance rating: high-end flame retardant formulations combined with the CO 2 foaming process, to produce high-quality flame retardant B1 extruded board, increase fire safety performance of the extruded board

5. Very low water absorption: ( ≤ 0.29%) has excellent hydrophobic, moisture and impermeability of the performance, and in can ensure that the thermal conductivity will not be reduced due to water absorption, thermal insulation performance can be maintained above 90%, superior Freeze-thaw resistance, and there will be no qualitative changes after long-term immersion or withstand repeated freeze-thaw cycles

XPS extruded polyphenylene insulation board underflooring packing with plastic bag