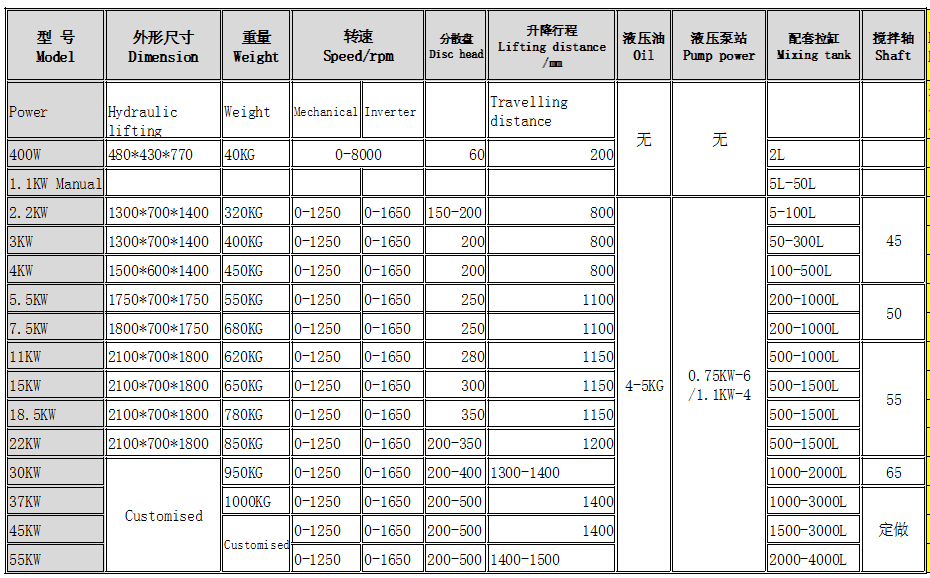

2. Mixing shaft : single shaft & double shaft

3. Function : mixing and dispersering

4. Lifting Way : hydraulic lift,mechanical lift

5. Motor power : Customized

6. Contact Material : stainless steel

7. Speed : controlled by frequency converter.

The matching

mixing tank

can also be

customized

If you want to know

more

about it, please

click

→

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

Conventional High Speed Dispersers consist of a driven vertical shaft and a high shear disk type blade.

The blade rotates at up to 5000 fpm and creates a radial flow pattern within a stationary mix vessel. The blade creates a vortex that pulls in the contents of the vessel to the blade's sharp edges. The blade surfaces then mechanically tear apart solids thereby reducing their size, and at the same time dispersing them among the liquid used as the carrier fluid.

High Speed Dispersers are ideal for dispersions that are up to a maximum of approx. 50,000 centipoise. When used in conjunction with Multi-Shaft Mixers, they can be useful to several hundred thousand centipoise.

Distribution box (control cabinet)

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

high speed mixer high speed agitator mixer high speed batch mixer

Dispersing machine is the most commonly used, economical and simple machine for paint processing.

1.With electric or manual steering system, easy and convenient to steer the headstock.

2.The adjustable working position enable the machine to work with several tanks, which enhances the machine usage rate greatly, reduce equipment investment and save space.

3.Various speed control

4.Low noise and long-time continuous operation.

5. Siemens or ABB motor for you and Siemens/Emerson Frequency inverter available

6. Non explosion-proof and explosion-proof type of production dispersing equipment are both as standard

7. Vacuum production high speed disperser is available.

1.One machine with multi-

vessels

2.Hydraulic lifting

3.Electric or manual rotation

4.lower cost of equipment invesment

5.Easy to operate and clean

6.Stable capability

7.Little air absorption during mixing and dispersing process makes it disperses and dissolves materials to smaller particle size efficiently .

8.The adjustable working position enable the machine to work with several tanks, which enhances the machine usage rate greatly, reduce equipment investment and save space.

9.Customized equipments are available.

We will offer you price referring to your detail request, so please kindly inform us of the material, viscosity, density, etc, and other requirements you prefer, and the special offer will be given.

The pictures are above just for your reference.

Our machines can be

customized

, leave an inquiry to know more details about price, packing, shipping and price.Any questions, feel free to contact us.