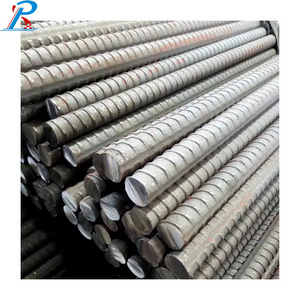

Rebar is the common name of hot rolled ribbed steel bar. The grade of ordinary hot-rolled steel bar consists of HRB and the

minimum yield point of the grade. H, R and B are the first letters of the words Hotrolled, Ribbed and Bars respectively. Hot

rolled ribbed steel bars are divided into two grades HRB335 (old number 20MnSi), three grades HRB400 (old number 20MnSiV,

20MnSiNb, 20Mnti) and four grades HRB500.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zehao

-

Model Number:

-

Customized

-

Application:

-

construction

-

Product name:

-

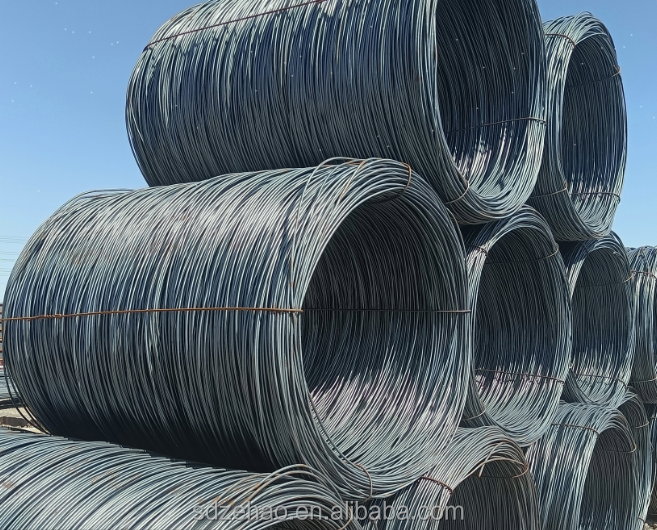

Threaded coil

-

Material:

-

HRB335 HRB400 HRB400E HRB500

-

Shape:

-

Coil

-

Technique:

-

Cold Rolled Hot Rolled

-

Keyword:

-

Steel Reabar

-

Main Application:

-

Cnstruction Building

-

MOQ:

-

5 Tons

-

Packing:

-

Standard Sea-worthy Packing

-

Payment Terms:

-

30%TT Advance + 70% Balance

Quick Details

-

Grade:

-

HRB400

-

Length:

-

Customized

-

Tolerance:

-

±1%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zehao

-

Model Number:

-

Customized

-

Application:

-

construction

-

Product name:

-

Threaded coil

-

Material:

-

HRB335 HRB400 HRB400E HRB500

-

Shape:

-

Coil

-

Technique:

-

Cold Rolled Hot Rolled

-

Keyword:

-

Steel Reabar

-

Main Application:

-

Cnstruction Building

-

MOQ:

-

5 Tons

-

Packing:

-

Standard Sea-worthy Packing

-

Payment Terms:

-

30%TT Advance + 70% Balance

Product Description

Rebar is widely used in housing, Bridges, roads and other civil engineering construction. Large to highways, railways, Bridges,

culverts, tunnels, flood control, DAMS and other public facilities, small to the foundation of housing construction, beams,

columns, walls, plates, rebar are indispensable structural materials. With the deepening of China's urbanization, the demand for

rebar is strong with the vigorous development of infrastructure construction and real estate.

culverts, tunnels, flood control, DAMS and other public facilities, small to the foundation of housing construction, beams,

columns, walls, plates, rebar are indispensable structural materials. With the deepening of China's urbanization, the demand for

rebar is strong with the vigorous development of infrastructure construction and real estate.

Specification

|

Product name

|

Threaded coil

|

|

Material

|

HRB335 HRB400 HRB400E HRB500

|

|

Shape

|

Coil

|

|

Technique

|

Cold Rolled Hot Rolled

|

|

Keyword

|

Steel Reabar

|

|

Main Application

|

Cnstruction Building

|

|

MOQ

|

5 Tons

|

Production process

1.

Ironmaking area

: The purpose of this area is to send iron ore, coke and limestone into the blast furnace for smelting. In this process, iron ore is broken down and pre-melted to produce pig iron, which is used as a raw material in the steelmaking process.The resulting pig iron is then sent to the steelmaking area.

2.

Main steelmaking area

: In this area, pig iron is fed into the converter (or electric arc furnace) and smelted together with scrap steel. This process involves blowing oxygen to remove impurities in order to convert to molten steel. The molten steel is then sent to the ladle furnace for refining, improving its quality and composition.

3.

Finishing area

: The slab pulled from the continuous casting machine is reached by different processing

routes to the hot rolling mill. In these machines, the slab is heated to the desired temperature and then a continuous small

rolling process is carried out to achieve the desired size and shape.

routes to the hot rolling mill. In these machines, the slab is heated to the desired temperature and then a continuous small

rolling process is carried out to achieve the desired size and shape.

4.

Thread processing area

: The goal of this area is to process hot rolled rebar to form threads on its surface. This is usually done by a wire roller, which creates a thread on the surface of the rebar by rolling it multiple times. 2

5.

Thread processing

: After the completion of the initial thread processing,the rebar needs to be further heat treated to improve its mechanical properties.

6.

Cooling and packaging

: the cooled rebar is further rolled and processed by the cold rolling mill, and then cooled, and finally tested for appearance quality, dimensional accuracy, chemical composition, etc., and the qualified products are packaged and ready to leave the factory.

Product application

1. Building structure

2. Civil engineering

3. Reinforced concrete construction

4. Infrastructure construction

5. Architectural

decoration

decoration

6. Industrial equipment

7. Other application areas

Packing & Delivery

1. The whole bundle is packed,the number of 12 meters fixed-length packaing is 5,and the 9 meters is 4,the packaging is firm.

2.The cutting interface should meet customer requirements,there is no elbow at the head and tail,and it is beautiful and neat.

3. The coiled wire is heavy in weight,trapped in four ways,and the packaging is firm.

3. The coiled wire is heavy in weight,trapped in four ways,and the packaging is firm.

Mode of transport:

1. Shipping

2. Auto transportation

3. Iron transportation

4. Air Freight

Hot Searches