- Product Details

- {{item.text}}

Quick Details

-

Output Speed:

-

250RPM

-

Warranty:

-

1 years

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JACTON

-

Structures:

-

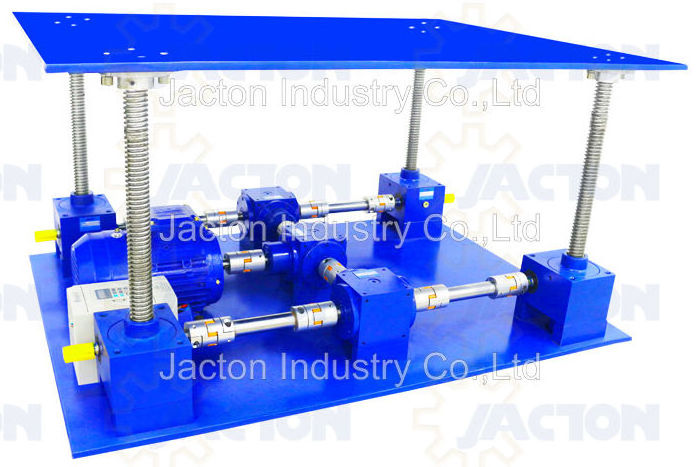

screw jack,bevel gearbox,coupling,drive shaft,motor

-

Load Capacity:

-

1t,2t,2.5t,3t,5t,10t,15t,20t,25t,30t,35t,50t,100t

-

Feature 1:

-

self locking, complete synchronization

-

Feature 2:

-

custom made stroke, 10-6000mm

-

Mount Type:

-

upright, or inverted

-

Feature 4:

-

precisely position, easy installation

-

Feature 3:

-

simultaneously lifting

-

Features 5:

-

operation and maintenance free

-

Drive System:

-

electric, motorized, or manual operated

-

Assembly Drawing:

-

2D, 3D model

-

Certification:

-

CE

Quick Details

-

Gearing Arrangement:

-

Worm

-

Output Torque:

-

15-1500NM

-

Input Speed:

-

1440RPM

-

Output Speed:

-

250RPM

-

Warranty:

-

1 years

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JACTON

-

Structures:

-

screw jack,bevel gearbox,coupling,drive shaft,motor

-

Load Capacity:

-

1t,2t,2.5t,3t,5t,10t,15t,20t,25t,30t,35t,50t,100t

-

Feature 1:

-

self locking, complete synchronization

-

Feature 2:

-

custom made stroke, 10-6000mm

-

Mount Type:

-

upright, or inverted

-

Feature 4:

-

precisely position, easy installation

-

Feature 3:

-

simultaneously lifting

-

Features 5:

-

operation and maintenance free

-

Drive System:

-

electric, motorized, or manual operated

-

Assembly Drawing:

-

2D, 3D model

-

Certification:

-

CE

| Manually lift a platform, crank screw mechanism for height adjustment manufacturer |

By connecting individual screw jacks with drive shafts lifting systems can be realized in a simple way. With the rich accessories many problems can be solved with the standard program.

JACTON Screw Jack System is usually used for lifting heavy duty load or lifting platform in automated production plants worldwide. Clients can choose mechanically linked 2-jacks system, 3-jacks system, 4-jacks system, 6-jacks system, 8-jacks system......14-jacks system for your practical application.

Screw jacks non-rotating Application examples Tank opening, Synchronous concrete shuttering adjustment, Conveyor belt height adjustment, Scissor lifting tables, Precise roller setting, Solar panel, Slider adjustment in silo, and Lifting platforms. The load bearing capacity of the drives and system components varies widely according to the installation situation and the operating duration. The limits specified in the data sheets must not be exceeded under any circumstances. Screw jacks are basically not suitable for continuous operation under load. The maximum operating duration depends on the load being moved and must not exceed the limit values.

Screw Jack System Efficiency: 2-jacks system with efficiency 95%, 3-jacks system with efficiency 90%, 4-jacks system with efficiency 85%, 6-jacks system with efficiency 80%, and 8-jacks system with efficiency 80%. Notes: don't ignore bevel gearbox efficiency 98%.

Jacks can be installed horizontally, perpendicularly or inclined. Before installing, however, be sure to select the correct (lifting or suspending) jack type. When using a jack for suspending, prepare oil pans because grease may run down through the screw shaft. The big product range offers a variety of worm gear screw jack designs and sizes. Heavy loads can be handled and high speeds can be achieved.

Screw Jack system is ruggedly designed and produced in standard models with load handling capacities from 1 ton to 100 tons. They may be used individually or in multiple arrangements. There are no "standard" travel lengths and all Screw Jack Systems are built to specification.

Screw Jack System Accessories: A complete line of AC, DC motors, geared motors, servo motors, stepper motors, handwheels, bevel gearboxes, couplings, universal joints, telescopic universal joints, connecting shafts, cardan shafts, limit switches, proximity switches, safety nut, travel nut, rod ends, stop nuts, pillow block bearings, flange blocks, bellows boots, protective tubes, motor flange nema or iec, encoder, potentiometer, frequency converter, position indicators, trunnion plate, trunnion mounting brackets, and motion control devices. We can provide the accessories you need to compliment your screw jack system and to ensure the efficient operation, extended life and safety of your system.

Variable Centre Straighteners utilise Screw Jacks for moving the centre straightening rollers, end pinch rollers. A jacking system for each straightening roller has two special design screw jacks and a strengthened gearbox. The pinch rollers have their position adjusted by two horizontally opposing screw jacks, driven individually by motorised helical gearboxes. Glass Packaging Machine Raising and lowering a carriage clamping mechanism on a glass packaging machine, which operates on a continuous duty cycle. Metric translating screw jacks, linked in an H configuration, fitted with two start screws and high performance gear sets, to meet the speed and duty requirements.

Shipping

:

1. Ocean freight: seaport to seaport, price terms CIF, FOB, EXW, CFR etc.

2. Air freight: airport to airport, price terms EXW, CRF etc.

3. Air courier: DHL, FEDEX, UPS, TNT door to door shipment, price terms DDU, CPT etc.

Packing:

100% standard exporting plywood cases.

Note: International Exporting Standard Wooden Material with Free Fumigation.

* One of the biggest orders with 1750 units screw jacks.

* Standard products with 2D Drawings(DXF, DWG, PDF) and 3D CAD Model(STEP).

* 100% quality assured with double quality inspections. Original Inspection Reports, Operation Manual, and Book Catalogue are put into the packages.

* 100% safety transportation with strong standard export plywood cases materials (free fumigation).

* International standard materials for all standard products.

* Custom design available, OEM service available, Free engineering advice and Customer label available.

1. Theatrical solutions stage and orchestra platform lifts projects. Customers are from France, Australia, Netherlands, United Kingdom, Spain and Canada.

2. Hydroelectric power station projects and water conservancy projects. Customers are from Vietnam, Australia, Malaysia, Belgium, United States and United Kingdom.

3. Aircraft maintenance platforms and docking systems projects. Customers are from Singapore.

4. Solar panel tracking system projects. Customers are from Spain, India and Canada.

5. Bolted steel storage tanks and silos lifting solutions. Customers are from South Africa, United States, Mexico and Vietnam.

6. Dish antenna elevation and azimuth positioning projects. Customers are from Singapore, Malaysia and United States.

7. Railway wagon projects. Customers are from South Africa.

8. Beverage can production lines. Customers are from Netherlands, United States, Thailand and Indonesia.

9. Steel factories production lines. Customers are from United States.

10. Continuous PU sandwich panel production lines. Customers are from Thailand and United Kingdom.

* Manual Screw Jacks.

* Electric Screw Jacks.

* Worm Gear Screw Jacks Series.

* Bevel Gear Screw Jack Series.

* Electric Cylinders Series.

* Spiral Bevel Gearboxes Series.

* Lifting Systems and Accessories.

* Electric Linear Actuators Series.

* Geared Motor and Gear Reducers Series.

1. American Countries:

United States, Mexico, Canada, Chile.

2. European Countries:

Germany, France, United Kingdom, Italy, Spain, Poland, Romania, Netherlands, Belgium, Greece, Czech Republic, Portugal, Sweden, Hungary, Austria, Switzerland, Bulgaria, Denmark, Finland, Slovakia, Norway, Ireland, Georgia, Slovenia.

3. Asian Countries:

Malaysia, Indonesia, Singapore, Philippines, Vietnam, Thailand, India, Israel.

4. Oceanian Countries:

Australia, New Zealand.

5. African Countries:

South Africa, Egypt.

JACTON INDUSTRY Co., Ltd (VAT No.: 9144190007026567X3) is one of the leading companies in the field of Screw Jacks(Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Linear Actuators, Gearmotors and Speed Reducers . We are an audited professional manufacturer and supplier by SGS (Serial NO.: QIP-ASI192186) and BV (Serial NO.: MIC-ASR202862) organizations. We have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, and consistently provide the customers with the best engineered solution for precision linear actuation, power transmission and mechanical jacking systems. Jacton Industry guarantees quality, reliability, performance and value for today′s demanding industrial applications.

FAQ

1. What type of payment methods do you accept?

We accept Wire transfer, Credit Card, Paypal, Alibaba Trade Assurance order, Western Union and L/C etc.

2. Can I get one sample to test?

Yes, sample can be at a normal price and welcomed. The transport fees are at your account.

3. How about the quality of your product?

Jacton industry is only focus on the field of Screw Jacks(Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Linear Actuators, Gearmotors and Speed Reducers.

4. OEM/ODM Accepted?

Yes, Please send you new product drawings or sample to us if you have, and we can custom-made as your required. We will also provide professional advices of the products to make the design to be maximize the performance.

5. If you can not find the product on our website,how do you do?

Please send us inquiry with product pictures and drawings by email or other ways you prefer, we'll check if we could produce.

6. Can I trust you?

Absolutely yes. Samples could be provided to test firstly, and we can use Alibaba trade assurance service to do business to guarantee both the seller and buyer's benefit, and we are golden supplier for years.

7. What's our products warranty?

One year quality guarantee for the products from your purchase date, except the human damage.