- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

32000

-

Power (kW):

-

57.5

-

Product name:

-

rubber sheet strip cutting machine

-

Application:

-

rubber sheet strip cutting

-

Material:

-

SUS304

-

Function:

-

cutting into strips

-

Keyword:

-

bench top rubber strip cutting

-

Advantage:

-

High Efficieccy

-

Product type:

-

rubber strip slicing

-

Motor power:

-

2.2kw

-

Operational way:

-

bottons

-

Control System:

-

Electric Control System

-

Marketing Type:

-

New Product 2021

Quick Details

-

Place of Origin:

-

JIA

-

Voltage:

-

380V/220v

-

Dimension(L*W*H):

-

30*3.5*5.5

-

Weight:

-

32000

-

Power (kW):

-

57.5

-

Product name:

-

rubber sheet strip cutting machine

-

Application:

-

rubber sheet strip cutting

-

Material:

-

SUS304

-

Function:

-

cutting into strips

-

Keyword:

-

bench top rubber strip cutting

-

Advantage:

-

High Efficieccy

-

Product type:

-

rubber strip slicing

-

Motor power:

-

2.2kw

-

Operational way:

-

bottons

-

Control System:

-

Electric Control System

-

Marketing Type:

-

New Product 2021

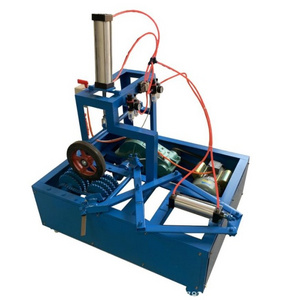

Rubber sheet strip cutting machine rubber slitter machine slicing and slitting rubber machine

1.The cutter used enchase project.it high speed steel material, sharp wear-resisting.

2.Main power adopt Taiwan three-phase deceleration brake motor, positioning

precision and durable.

Chain transmission, cutting 90 ° fluorine rubber, easy.

3.The feeding parts adopt PLC and stepping motor control, double cylinder

pressure, this round of synchronization roller, feeding accuracy.

4.The operation is simple, only need to input the required width computer can work.

5. Cutting process, the width can be adjusted freely blanking.

| Model | NLQ-QTJ-600 |

| Feeding Sheets Thickness | 1-20mm |

| Feeding Sheets width | 580mm |

| Feeding Sheets Max width | No limit |

| Feeding Sheets Minnum width | 2mm |

| Travel times | 90times/min |

| Tolerance | ±0.05mm |

| Machine Weinght | 550kg |

| Motor Power | 2.2/3.0kW |

| Machine Size | 1330*1340*1210mm |

1. Best service from the machines inspection testing, delivery and installation guide;

2. Supply the Instructions on manuals of the Operation and Maintainance;

3. 24 hours on line serice to guide or instruct on the installation, commissioning and operation properly;

4. Service at project site if available. If can't, we can video call on internet.

5. Spare parts supply as best convinience for purchasers.