- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Name:

-

hard anodizing Acid Zinc Plating Plant electroplating galvanic bath

-

Plating style:

-

Chemical Plating

-

Heating model:

-

Electric Heating, hot water, steam

-

Material of tank:

-

PP PVC

-

Application:

-

Surface Treatment

-

Operation type:

-

Local Operation

-

OEM Service:

-

Accept

-

After-sales Service:

-

Service Machinery Overseas

-

Auxiliary Equipment:

-

Rectifier, filter, dryer

-

Weight:

-

Customized

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Electroplating

-

Brand Name:

-

Qinding

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Name:

-

hard anodizing Acid Zinc Plating Plant electroplating galvanic bath

-

Plating style:

-

Chemical Plating

-

Heating model:

-

Electric Heating, hot water, steam

-

Material of tank:

-

PP PVC

-

Application:

-

Surface Treatment

-

Operation type:

-

Local Operation

-

OEM Service:

-

Accept

-

After-sales Service:

-

Service Machinery Overseas

-

Auxiliary Equipment:

-

Rectifier, filter, dryer

-

Weight:

-

Customized

-

Certification:

-

ISO9001

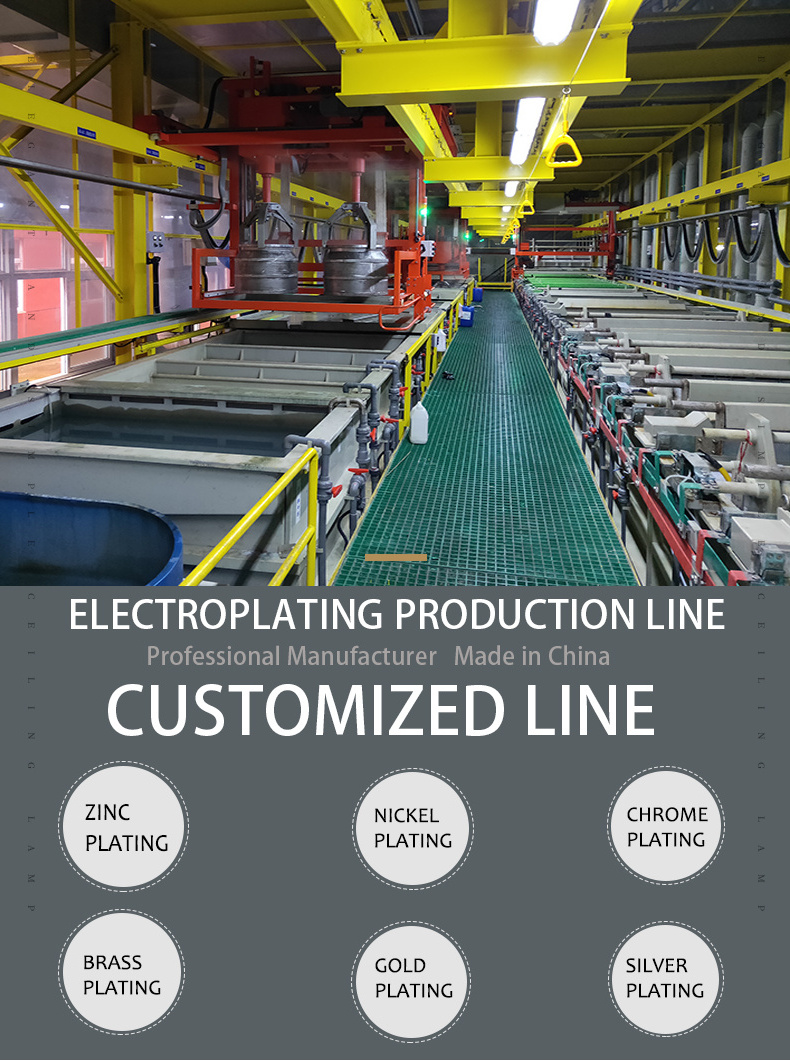

hard anodizing Acid Zinc Plating Plant electroplating galvanic bath

| Product Name | hard anodizing Acid Zinc Plating Plant electroplating galvanic bath |

| Usage | Metal Surface Plating |

| Material | PP plate, Motor, etc. |

| Heating source | Electricity, Steam or hot water |

| Auxiliary equipment | Rectifier, Filter, dryer, temperature control system, water-cold machine, etc. |

| Feature | High production efficiency, uniform plating |

| Application | Galvanizing plating, Copper plating, Nickel plating, Gold plating, Anodizing |

| Size | Can be customized |

| Volume | According to your application performance |

| Warranty time | 3 year |

Tank Track Water pipe system Copper

Barrel Parts Rack Tank Rack

Semi-automatic Full automatic High orbit Single arm

Frame Water Tray Stairs Sidewalk

Rectifier Recirculation pump Centrifugal spin dryer Ultrasonic

Chiller RO machine Oven Control box

Temperature controler Electric Heating Air agitation Titanium Basket

Lateral extraction Fan motor of extraction extraction tower Pipes

Electroplating production line configuration features:

(1) The tank body can be made of PP, PVC material and stainless steel according to customer requirements, resistant to acid and alkali and temperature.

(2) The rack can be assembled with carbon steel and stainless steel racks. The running rails in the rack are divided into high, medium and low rails, which are beautiful and durable.

(3) Independent electrical control cabinet, PLC full program control, can also be manually operated.

(4) PP high-precision filter and imported chemical pump, acid and alkali resistant.

(5) High-power DC electroplating power supply, quality assurance, safe operation, low noise, easy maintenance

(6) Driving can be driven by a single motor or dual-motor. The lift is driven by a nylon reinforced belt that is extremely quiet and requires no lubrication.

(7) The barrel plating line can be equipped with a drum self-rotating drip device. The drum can be made of PP, PVC sheet or die-casting material with a diameter of 1-5mm.

(8) The transmission device is equipped with a full-line shaft transmission and a single-machine transmission structure.

(9) The lifting load of the vehicle is routinely up to 100-250kg.

(10) Customized upper and lower devices and manual loading and unloading devices can be customized according to customer requirements or with an automatic drying system.

Q: Are you a trading company or manufacturer?

A: We are a factory.

Q: What's your delivery time?

A: About 15-60days, it's based on specific projects.

Q: We need a anodizing machine for aluminum, could you send me a quotation?

A: Because the hard anodizing is always customized for different products, we'd like to send you a quotation and make the design for you based on knowing detailed information from you first.

Q: What is the necessary information you need for design?

A: The plating process you have, the capacity of your per products, the material, weight, size, and surface area of your per product, The thickness of plating layer, Your working hours per day, Type of salt spray test and time, Workshop dimension and so on

|

Jason

Sales Manager

|