- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ 3PH

-

Dimension(L*W*H):

-

1450 *750*1500mm

-

Weight:

-

285 KG

-

Power:

-

8250

-

Working Temperature Range:

-

-20 to 55 celsius degree

-

Product Name:

-

Air To Water Chiller

-

Cooling Capacity:

-

6Ton/20kw

-

Refrigerant:

-

R22/R134a/R407c/R410a/R404A

-

Compressor Power:

-

3.5kw*2

-

Condenser Type:

-

Efficiency Copper Aluminum Fins

-

Evaporator type:

-

Stainless Steel coil +Tank

-

Water Tank Capacity:

-

120L

-

Chilled Water:

-

3.71m3/h

-

Water Pump Power:

-

0.75kw

-

Outlet Water Temperature Range:

-

5 to 35 ℃

Quick Details

-

Condition:

-

Brand new

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TopChiller

-

Voltage:

-

380V 50HZ 3PH

-

Dimension(L*W*H):

-

1450 *750*1500mm

-

Weight:

-

285 KG

-

Power:

-

8250

-

Working Temperature Range:

-

-20 to 55 celsius degree

-

Product Name:

-

Air To Water Chiller

-

Cooling Capacity:

-

6Ton/20kw

-

Refrigerant:

-

R22/R134a/R407c/R410a/R404A

-

Compressor Power:

-

3.5kw*2

-

Condenser Type:

-

Efficiency Copper Aluminum Fins

-

Evaporator type:

-

Stainless Steel coil +Tank

-

Water Tank Capacity:

-

120L

-

Chilled Water:

-

3.71m3/h

-

Water Pump Power:

-

0.75kw

-

Outlet Water Temperature Range:

-

5 to 35 ℃

CE Certificated Plastic Blowing Bottle Machine Used 8HP 6Ton Air to Water Industrial Chiller System

Air to Water Chiller is a refrigeration-based cooling device that produces a cooling effect by releasing heat out of the system through chilled air circulating over-processed water.

TopChiller is an appreciated, most proficient manufacturer and supplier of Air to Water Chiller in China working for last twenty years.

TopChiller has introduced the world marketplace with a full line of varying capacity Air to Water Chiller for cooling purposes, working with appreciating credentials since 1999.

Air to Water Chiller is made of scroll and screw compressor, air-cooled condenser, water tank, air filters, condenser fans, power supply, heat exchanger, control panel, expansion valves, and protecting devices, etc.

Air to Water Chiller is used in a variety of applications ensuring cooling effect as:

Blow molding, plastic industry processing, laser processing, commercial applications, cement cooling, chemical designing, HVAC system, printing, hydraulics oil cooling, injection molding, laboratory, pharmaceutical, semiconductor, thermoforming, welding, and injection molding, etc.

Air To Water Chiller Features and Advantages:

(1).Adopted world famous brand compressors and high efficiency condenser and evaporator, ensure high cooling efficiency, low energy consumption, low noise and long service life.

(1).100% original brand parts, including compressor, electrical components and refrigeration components.

Danfoss/Copeland scroll compressor.

Schneider electrical components.

Danfoss/Emerson thermal components.

(3). Self-processing components: Condenser, Evaporator, SS storage tank and Cabinet self-processing.

(4).Copper coil built in SS tank evaporator, easy for cleaning and installation(plat type, shell and tube available on request).

(5).Refrigerant: R22 charged, CFC free type R407C, R410A, R134A for option.

(6).Over-sized evaporator and condenser ensure the chiller unit could running under 45° C high ambient temperature.

(7).Microcomputer control system offering accurate temperature stability within +1° C

(8).Multi-protection devices ensure the chiller unit running safety.

(9).The innovative evaporator-in-tank configuration ensure a steady water temperature offered, as the evaporator also cools the tank itself, reduces ambient heat again, and increases the efficiency.

(10).Energy efficient solutions: our specialists are aware of the rising cost of energy and the pressure to reduce energy consumption, and offer many energy saving products that favor life time costs including variable speed pump & fan packages and energy efficient refrigeration products.

(11).Low noise and big volume air blower.- Standard equipped Iron pump, stainless steel or high lift pump for option.

(12). air cooled industrial chiller adopted aluminum fin/copper tube type condenser, easy for cleaning and installation.

6Ton 20Kw Air to Water Cooled Chiller Specification

|

Air to Water Chiller Model |

AC-8AD |

|||

|

nominal cooling capacity |

kcal/h |

18576 |

||

|

Kw |

21.6 |

|||

|

M ax power consumption |

kw |

8.25 |

||

|

F ull load |

A mp |

20 |

||

|

power s ource |

|

3 PH -380 V -5 0HZ |

||

|

refrigerant |

type |

|

R407c/R410a |

|

|

control |

|

external balance of thermal expansion valve |

||

|

compressor |

type |

|

hermetic scroll type |

|

|

p ower |

kw |

3.5 × 2 |

||

|

condenser |

type |

|

Efficient aluminum finned copper sleeve+low noise external rotor fan |

|

|

air volume |

m 3 /h |

8000 |

||

|

fan motor |

kw |

0.25 × 2 |

||

|

evaporator |

type |

|

Coil in water tank exchanger |

|

|

coolant flow |

m 3 /h |

3.71 |

||

|

Water tank capacity |

L |

120 |

||

|

inlet and outlet connection(BSP) |

inch |

1 -1/2 |

||

|

P ump |

P ower |

K w |

0.75 |

|

|

M ax flow rate |

m 3 /h |

8.1 |

||

|

M ax head |

M |

20 |

||

|

safety devices |

Compressor overheating protection, over-current protection,high and low pressure protection, over-temperature protection,traffic protection,phase sequence /phase loss protection,low level protection,frost protectio n |

|||

|

dimension |

mm |

1450*750*1500 |

||

|

weight |

kg |

285 |

||

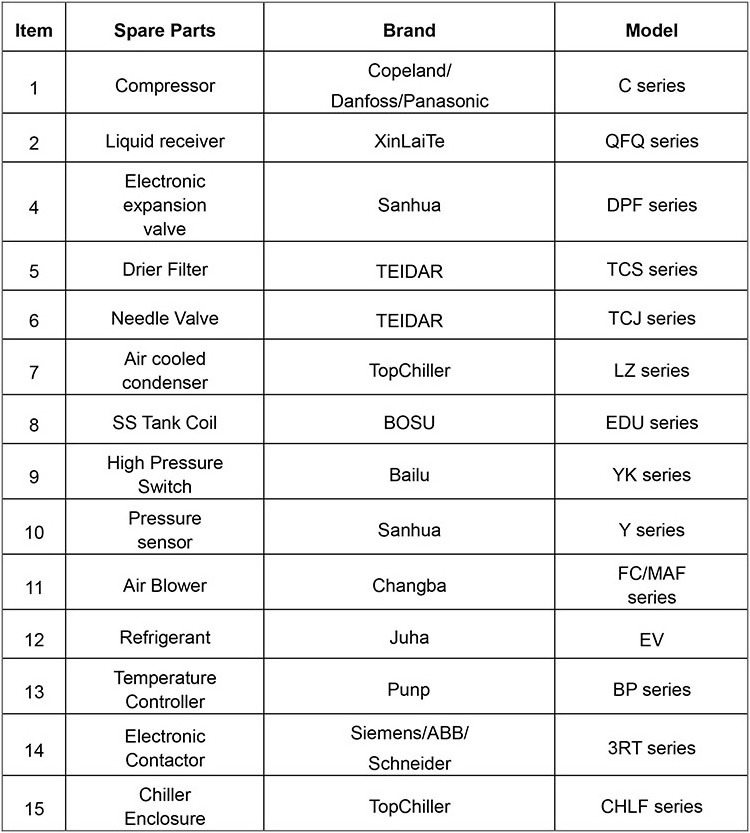

Air To Water Chiller Main Refrigeration Configuration Table

Air To Water Chiller Main Part