- Product Details

- {{item.text}}

Quick Details

-

Enrichment Ratio:

-

50 times

-

Stars No.:

-

1-4 starts available, each start with 5 spirals

-

Spiral Material:

-

FRP

-

External dia(mm)::

-

400-2000

-

Installation Service:

-

Send Technician or Provide Video

-

Sample Test:

-

Supply

-

After sale service:

-

Supply

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Name:

-

Gold Washing Spiral Chute

-

Benificiation Ores:

-

iron, tin, tungsten, tantalum, niobium, gold, coal etc

-

Enrichment Ratio:

-

50 times

-

Stars No.:

-

1-4 starts available, each start with 5 spirals

-

Spiral Material:

-

FRP

-

External dia(mm)::

-

400-2000

-

Installation Service:

-

Send Technician or Provide Video

-

Sample Test:

-

Supply

-

After sale service:

-

Supply

Hot Sale Gravity Gold Washing Plant Gold Washing Spiral Chute with Centrifugal Force

Spiral concentrator, a kind of gravity concentration equipment, is usually applied at the first period of mining after the minerals are grinded into proper sizes (alluvial minerals do not need to be crushed or grinded). The main purpose by using the spiral concentrator is to enrich the useful minerals and get rid off useless materials.

| >> Brief introduction of Gold Washing Spiral Chute |

The Gold Washing Spiral Chute is new equipment with the domestic advanced level, successfully invented by Beijing General Research Institute of Mining and Metallurgy. It is applied for processing iron, tin, tungsten, tantalum, niobium, gold, coal, monazite, rutile, zircon and other metal, nonmetal minerals with enough specific gravity dispersion of granularity ranged from 0.02 to 0.3mm .

The Gold Washing Spiral Chute is our company's concentrating experienced scientific product, which is the best concentrating equipment, especially for concentrating sand ore in beach, riverside, seashore and stream .

5LL-1200 Gold Washing Spiral Chute is one of the most popular models:

The Gold Washing Spiral Chute is made of the fiberglass lined with wear-resistant polyurethane and corundum cover; the advantages are light, moisture proof, anti-rust, wear proof, anti corrosion and no noise, properly suitable for the different feeding particle sizes and grades. It is the domestic advanced level, the new highly effective equipment.

The Gold Washing Spiral Chute is a gravity equipment. With the water, action of gravity friction force, minerals would be separated by its gravity difference. Then we could get heavy, middling and light products .

| >> Advantages of Gold Washing Spiral Chute |

l Reasonable structure and small occupation area

l High recovery, high efficiency Gold Washing Spiral Chute

l Precise separation Gold Washing Spiral Chute

l Non-required power

l Light in weight, anti corrosion, rust and wear resistant

l Simple installation and Minimal maintenance requirements

l Low operating cost and long working life

l Reliable running with minimal operator attention

l Strong adaptability to fluctuation of feeding amount, density, size and grade

l The surface of corundum forms strong friction the concentration effect surpass plastic surface

|

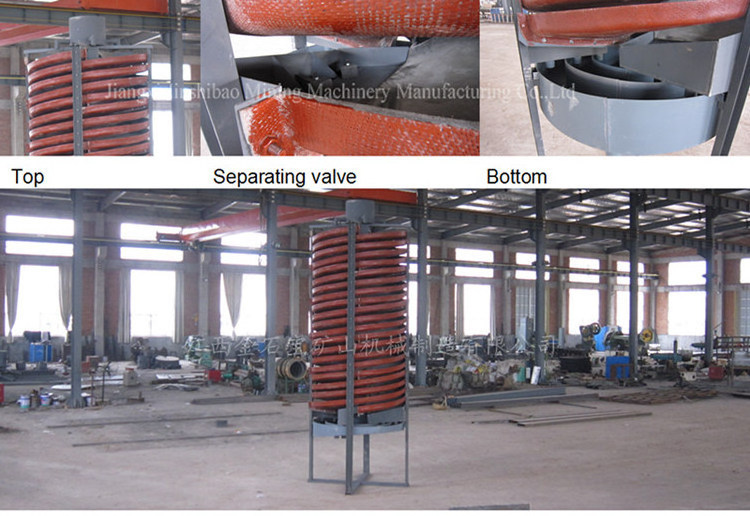

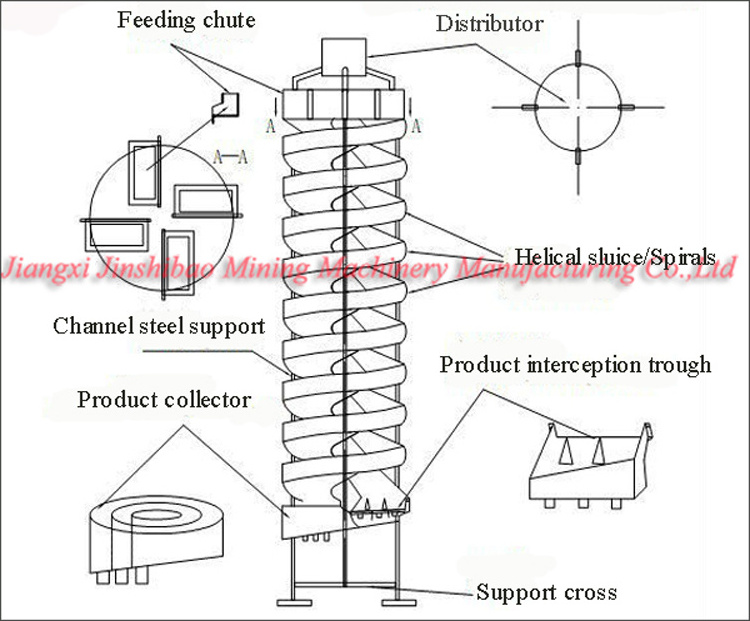

>> Structure

of Gold Washing Spiral Chute

|

The Gold Washing Spiral Chute mainly consists of the following parts: channel steel support, feeding box, helical sluice, product separator, bottom collector, and distributor.

| >> Specifications of Gold Washing Spiral Chute |

|

Model |

5LL-1500 |

5LL-1200 |

5LL-900 |

5LL-600 |

BLL-2000 |

|

|

Diameter (mm) |

1500 |

1200 |

900 |

600 |

2000 |

|

|

Spiral Distance (mm) |

540,720 |

720,540 |

540,405 |

450,360 |

1200 |

|

|

Max Number Spiral |

1-4 |

1-4 |

1-4 |

1-3 |

1-3 |

|

|

Feeding Range (mm) |

0.3-0.02 |

0.3-0.03 |

0.3-0.03 |

0.3-0.03 |

4-0.04 |

|

|

Feeding Density (%) |

25-55 |

25-55 |

25-55 |

25-55 |

20-45 |

|

|

Capacity (t/h) |

8--6 |

4--6 |

2--3 |

0.8-1.2 |

15-40 |

|

|

Outline Size |

L(mm) |

1560 |

1360 |

1060 |

700 |

2300 |

|

W(mm) |

1560 |

1360 |

1060 |

700 |

2300 |

|

|

H(mm) |

5260/4360 |

5260/4360 |

4000/3325 |

2600 |

6500 |

|

|

>> Successful engineering sites

of Gold Washing Spiral Chute

|

The spiral separators are widely applied in South Asia for mining.

LCL:

The Gold Washing Spiral Chute is packed ine steel frame. If the quantity is small, the machine will be packed after assembling.

FCL:

The spiral separators will be loaded in container disassembled.

| Payment Terms of Gold Washing Spiral Chute |

| • We usually accept T/T, L/C |

| • T/T: 30% of total amount as deposit, 70% balance before delivery. |

| • We will take pictures of finished products to you before delivery. |

|

Way of Packing

of

Gold Washing Spiral Chute

|

| • FCL & LCL export standard container 20/40 feet. |

| • FCL: Sea-worthy package. Machines are fixed in container; spare parts are packed in wooden boxes. |

| • LCL: Machines are packed in steel frame with plywood boxes. Customized package is available. |

|

Shipping

of

Gold Washing Spiral Chute

|

|

• By sea shipment

Gold Washing Spiral Chute

|

| MSK/MSC/APL/EMC/PIL and so on |

|

• By air shipment

Gold Washing Spiral Chute

|

|

• By courier express

Gold Washing Spiral Chute

|

| The lab equipment could be delivered by the courier express, such as UPS, DHL etc. |