- Product Details

- {{item.text}}

Quick Details

-

Hardness:

-

Full Hard

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Liange

-

Application:

-

Building Roofing tileCeilling

-

Width:

-

600-1250mm

-

Grade:

-

DX51D

-

Key word:

-

Colored corrugated steel plate

-

Surface finish:

-

Customer's Request

-

Material Grade:

-

ASTM/AISI/SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX

-

Technique::

-

Cold Rolled Hot Rolled galvanized

-

Payment term:

-

30%TT Advance + 70% Balance

-

Price term:

-

FOB CIF CFR

-

MOQ:

-

1Ton

-

Package:

-

Standard Sea Worthy Package

-

Color:

-

Customer's Request

Quick Details

-

Thickness:

-

0.12-0.13MM

-

Coating:

-

Z10-Z29

-

Spangle Type:

-

Regular Spangle

-

Hardness:

-

Full Hard

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Liange

-

Application:

-

Building Roofing tileCeilling

-

Width:

-

600-1250mm

-

Grade:

-

DX51D

-

Key word:

-

Colored corrugated steel plate

-

Surface finish:

-

Customer's Request

-

Material Grade:

-

ASTM/AISI/SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX

-

Technique::

-

Cold Rolled Hot Rolled galvanized

-

Payment term:

-

30%TT Advance + 70% Balance

-

Price term:

-

FOB CIF CFR

-

MOQ:

-

1Ton

-

Package:

-

Standard Sea Worthy Package

-

Color:

-

Customer's Request

Rroduct Details

|

Production Name:

|

Galvalume vs galvanized steel gutters aluzinc corrugated aluminum roofing sheets

|

|

Brand:

|

LIANGE

|

|

Model Number:

|

0.16-1.2mm*600-1250mm*C

|

|

Standard:

|

AISI, ASTM, BS, DIN, GB, JIS, AS ETC

|

|

Thickness:

|

0.12-3.5mm

|

|

Width:

|

914mm,1000mm,1200mm,1219mm,1220mm,1250mm 1500mm Or According To Customer's Requirement

|

|

Length:

|

In Coil Or According To Customer's Demends

|

|

Coil Weight:

|

3-8 Tons

|

|

Coil ID:

|

508/610mm

|

|

Color:

|

RAL Code Or According To Customer's Sample

|

|

Spangle:

|

No spangle, With spangle

|

|

Zinc Coating:

|

30-275g/m2

|

|

MOQ:

|

5 Tons

|

|

Package:

|

Standard Sea Worthy Package

|

|

Departure Port:

|

Any Port In China

|

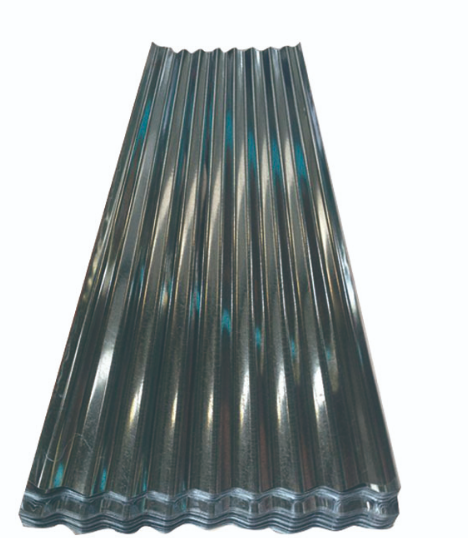

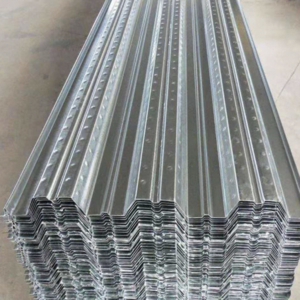

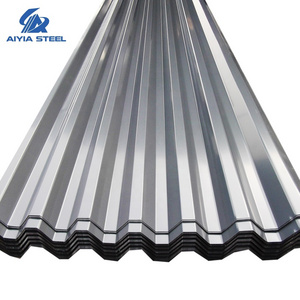

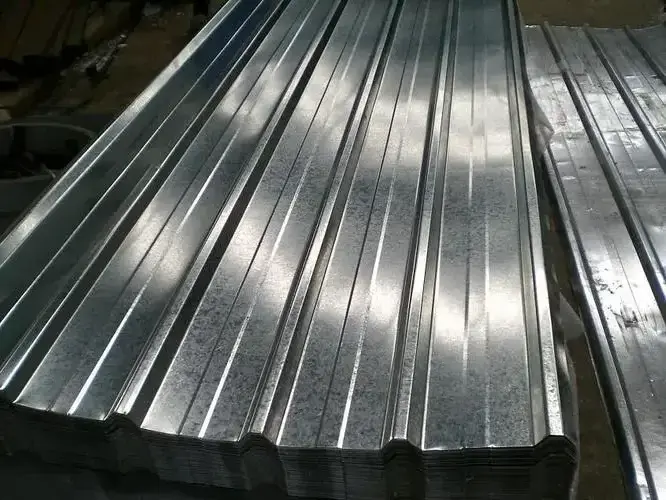

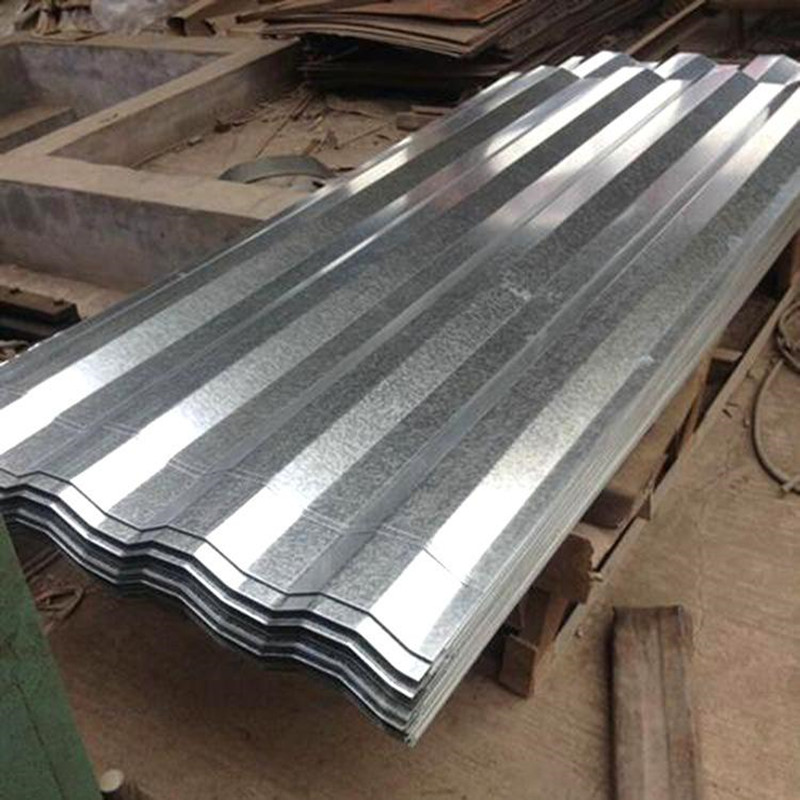

Galvanized corrugated sheet

Corrugated plate is also called pressure plate, the use of color coated steel plate, galvanized plate and other metal plate by rolling cold bending into a variety of wave shape of the pressure plate.

Production Process

1. Material Preparation: The production process begins with the selection of high-quality base materials, such as galvanized steel or aluminum sheets. These sheets are cleaned and coated with a corrosion-resistant layer, such as zinc or aluminum-zinc alloy.

2. Corrugation: The coated sheets are then passed through a corrugation machine, which molds them into the characteristic wavy shape. This process improves the structural strength of the sheets while maintaining their flexibility.

3. Coating Application: A primer coat is applied to the corrugated sheets to enhance adhesion. Afterward, a colored coating layer is added using a roller or spray application method. This layer provides the desired appearance and protects the underlying metal from corrosion and weathering.

4. Curing: The coated sheets are subjected to a curing process, which typically involves heating them in an oven or passing them through a curing chamber. This ensures proper bonding and drying of the coating layers.

5. Cutting and Shaping: The cured sheets are cut into desired lengths and can be further shaped according to specific requirements. Common shapes include sinusoidal (S-shaped) and trapezoidal profiles.

2. Corrugation: The coated sheets are then passed through a corrugation machine, which molds them into the characteristic wavy shape. This process improves the structural strength of the sheets while maintaining their flexibility.

3. Coating Application: A primer coat is applied to the corrugated sheets to enhance adhesion. Afterward, a colored coating layer is added using a roller or spray application method. This layer provides the desired appearance and protects the underlying metal from corrosion and weathering.

4. Curing: The coated sheets are subjected to a curing process, which typically involves heating them in an oven or passing them through a curing chamber. This ensures proper bonding and drying of the coating layers.

5. Cutting and Shaping: The cured sheets are cut into desired lengths and can be further shaped according to specific requirements. Common shapes include sinusoidal (S-shaped) and trapezoidal profiles.

Product Shown

Color coated galvanized corrugated sheet

Specification

1. Roofing and Cladding: Coated corrugated sheets are extensively used for roofing and cladding applications in residential, commercial, and industrial buildings. They provide weather protection, insulation, and enhance the aesthetic appeal of the structure.

2. Agricultural Buildings: These sheets are commonly utilized in agricultural buildings such as warehouses, barns, and poultry farms. They protect the livestock and stored goods from harsh weather conditions, ensuring a safe and controlled environment.

3. Industrial Sheds and Warehouses: Coated corrugated sheets are ideal for constructing industrial sheds, warehouses, and factories. They offer structural stability, fire resistance, and efficient utilization of space.

4. Wall Partitions and Fences: The versatility of coated corrugated sheets allows them to be used as wall partitions and fences.They provide privacy, security, and a contemporary appearance.

5. Interior Design: Coated corrugated sheets are increasingly being used in interior design projects for their aesthetic appeal.They can be applied to ceilings, walls, and decorative elements, adding texture and visual interest to spaces.

6. Advertisement Signage: Due to their vibrant colors and customized finishes, coated corrugated sheets are popular for creating eye-catching advertisement signage and display boards.

2. Agricultural Buildings: These sheets are commonly utilized in agricultural buildings such as warehouses, barns, and poultry farms. They protect the livestock and stored goods from harsh weather conditions, ensuring a safe and controlled environment.

3. Industrial Sheds and Warehouses: Coated corrugated sheets are ideal for constructing industrial sheds, warehouses, and factories. They offer structural stability, fire resistance, and efficient utilization of space.

4. Wall Partitions and Fences: The versatility of coated corrugated sheets allows them to be used as wall partitions and fences.They provide privacy, security, and a contemporary appearance.

5. Interior Design: Coated corrugated sheets are increasingly being used in interior design projects for their aesthetic appeal.They can be applied to ceilings, walls, and decorative elements, adding texture and visual interest to spaces.

6. Advertisement Signage: Due to their vibrant colors and customized finishes, coated corrugated sheets are popular for creating eye-catching advertisement signage and display boards.

Our Company

Packaging & Shipping

FAQ

1. How can I get a quotation from you ?

You can leave us message, and we will reply every message in time. Or we may talk on line by Trademanager.And you can also find our contact information on contact page.

2.Can I get samples before order ?

Yes, of course. Usually our samples are free. we can produce by your samples or technical drawings. We can build the moldsandfixtures.

3. what is your delivery time ?

The time of delivery is usually around 1 month(1*40FT as usual).We can send out in 7 days, if it has stock.

4.What is your payment terms?

Our usual payment term is 30% T/T deposite, and rest against B/L. EXW,FOB,CFR,CIF,DDU.

5. How can you garantee what I got will be good ?

We are factory with 100% predelivery inspection which garantee the quality.

6 How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them.

You can leave us message, and we will reply every message in time. Or we may talk on line by Trademanager.And you can also find our contact information on contact page.

2.Can I get samples before order ?

Yes, of course. Usually our samples are free. we can produce by your samples or technical drawings. We can build the moldsandfixtures.

3. what is your delivery time ?

The time of delivery is usually around 1 month(1*40FT as usual).We can send out in 7 days, if it has stock.

4.What is your payment terms?

Our usual payment term is 30% T/T deposite, and rest against B/L. EXW,FOB,CFR,CIF,DDU.

5. How can you garantee what I got will be good ?

We are factory with 100% predelivery inspection which garantee the quality.

6 How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them.

Contact Us

Hot Searches