- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MP3 Bluetooth Player

-

Copper Thickness:

-

0.5oz - 6.0oz

-

Min. Hole Size:

-

6mil, 4mil-laser drill

-

Min. Line Width:

-

3mil

-

Min. Line Spacing:

-

3mil

-

Surface Finishing:

-

HASL,Nickle

-

Product name:

-

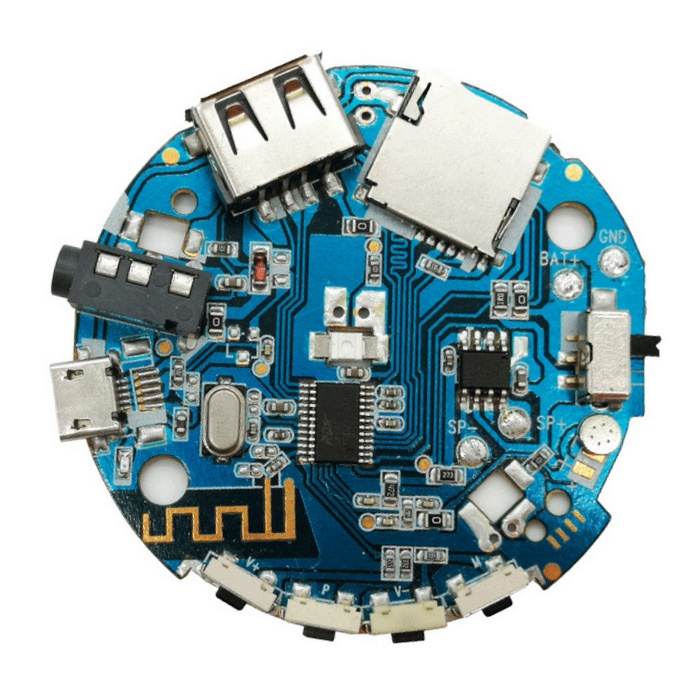

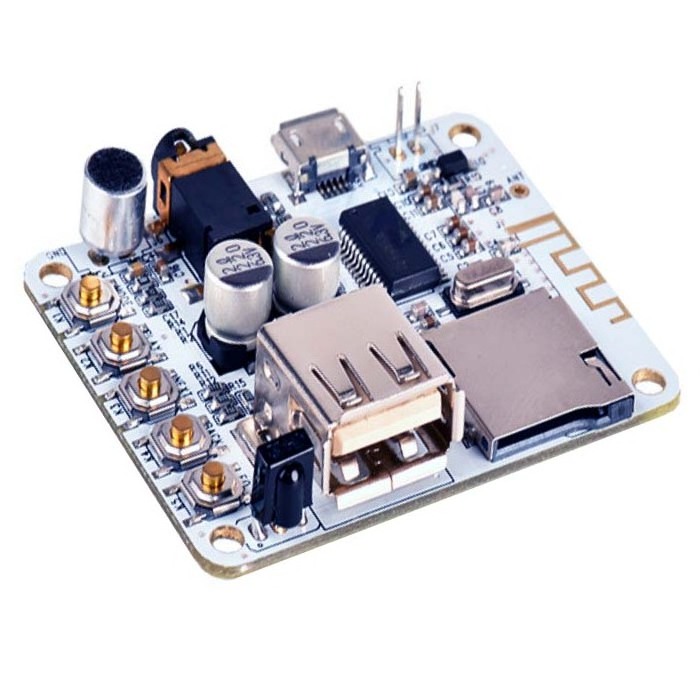

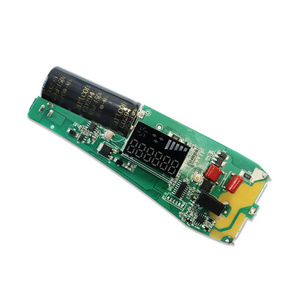

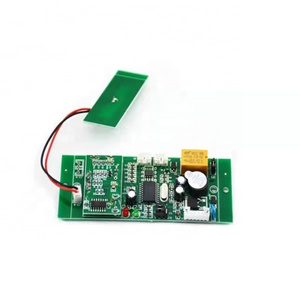

mp3 player PCB

-

Type:

-

Electronic Board

-

Application:

-

Large,Medium and Small Projects

-

Material:

-

FR4 /aluminum/ceramic CEM1

-

PCB Standard:

-

IPC-A-610 D/IPC-III Standard

-

Layer:

-

1-32 Layers

-

MOQ:

-

1 PCS

-

Package:

-

Vacuum Package

-

PCBA service:

-

SMD SMT DIP Component Assembly

-

Color:

-

Red Blue Green Black White

Quick Details

-

Base Material:

-

FR-4 glass epoxy

-

Board Thickness:

-

1.6mm

-

Model Number:

-

YD-K045

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MP3 Bluetooth Player

-

Copper Thickness:

-

0.5oz - 6.0oz

-

Min. Hole Size:

-

6mil, 4mil-laser drill

-

Min. Line Width:

-

3mil

-

Min. Line Spacing:

-

3mil

-

Surface Finishing:

-

HASL,Nickle

-

Product name:

-

mp3 player PCB

-

Type:

-

Electronic Board

-

Application:

-

Large,Medium and Small Projects

-

Material:

-

FR4 /aluminum/ceramic CEM1

-

PCB Standard:

-

IPC-A-610 D/IPC-III Standard

-

Layer:

-

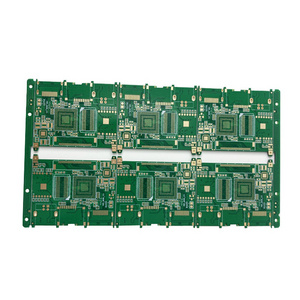

1-32 Layers

-

MOQ:

-

1 PCS

-

Package:

-

Vacuum Package

-

PCBA service:

-

SMD SMT DIP Component Assembly

-

Color:

-

Red Blue Green Black White

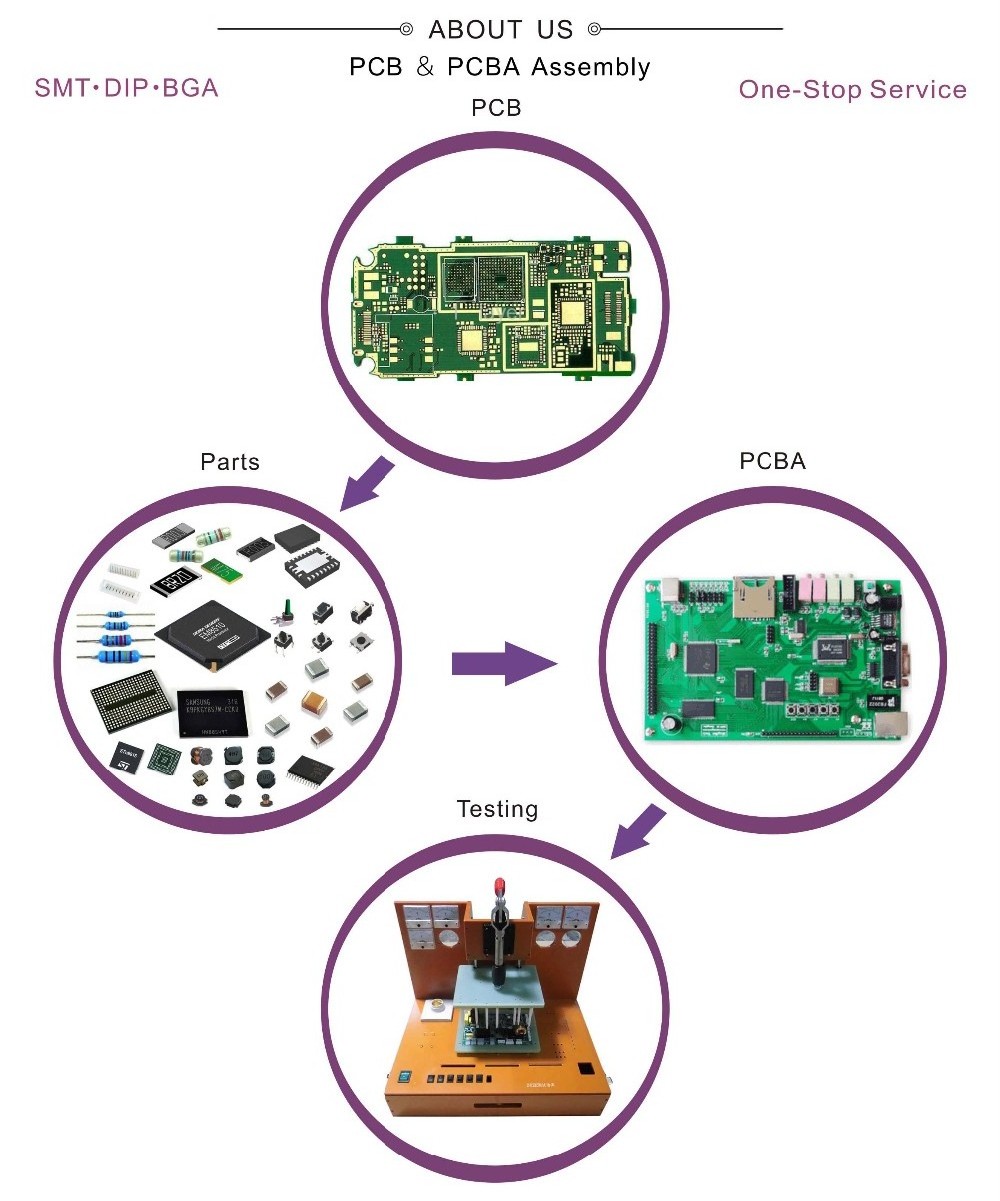

PCBA Assembly Capability

(1) 7 high-speed SMT precision equipment

(2) 1 DIP through hole welding production line

(3) 2 assembly test production lines

(4) 1 product packaging line

(5) All assemblies are ROHS compliant

PCBA Assembly Service

(1) PCBA prototype assembly

(2) PCBA batch assembly

(3) SMD surface mount technology

(4) DIP jack welding assembly

(5) BGA ball array assembly

Capability and Services Range:

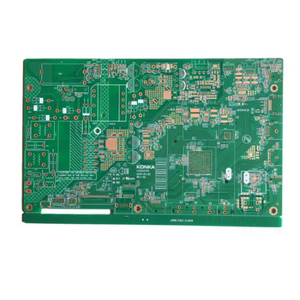

1.PCB circuit layout and production

2.Plastic and metal casing design services

3.Product customized packaging design

4.SMT/SMD parts assembly and DIP through hole soldering(PCBA)

5.IC programming software(pre-programmed), PCBA functional testing and verification

6.Complete product assembly(including plastic,metal casing,PCBA motherboard,cables, swithes and other components, etc.

7.ROHS environmentally protection material supply

8.Logistics arrangements, importing and exporting goods from China

| NO. | Item | Specification |

| PCB Manufacturing Capabilities | ||

| 1 | PCB layers | 1 to 32 layers |

| 2 | PCB board material type | FR4,High-TG FR4,CEM-1,ALU,CEM-3,Rogers,HDI,etc. |

| 3 | Max dimension | 600 x 1200mm |

| 4 | Min line width | 0.1mm |

| 5 | Min spacing | 0.1mm |

| 6 | Dimension tolerance | ±0.1mm |

| 7 | Min hole diameter | 0.2mm |

| 8 | Pcb board thickness coverage | 0.2 to 6.0mm |

| 9 | Min copper thickness in hole | 0.02mm |

| 10 | DK thickness | 0.08 to 6.0mm |

| 11 | NPTH size tolerance | ±0.025mm |

| 12 | PTH size tolerance | ±0.025mm |

| 13 | Dimension tolerance | ±0.1mm |

| 14 | Hole position tolerance | 0.075mm |

| 15 | Laser drill hole size | 0.1mm |

| 16 | Min soler mask | 0.01mm |

| 17 | Minimum size of solder mask separation ring | 0.05mm |

| 18 | Max board twist and wrap | ≤1% |

| 19 | Finished hole diameter | 0.2 to 6.0mm |

| 20 | Flame resistance | 94V-0 |

| 21 | Impedance control tolerance | ±5% |

| 22 | Outer layer copper thickness | 8.75 to 175um |

| 23 | Inner layer copper thickness | 17.5 to 175um |

| 24 | Solder mask type | Blue,Green,Black,Yellow,Red,White |

| 25 | Surface finish | HASL,OSP, ENIG, Gold plating,Immersion Tin,etc. |

Q1, who are we? Why choose us?

A1: We are an electronics manufacturing services (EMS) supplier, we provide customers with flexible and reliable electronic

manufacturing solutions, from parts procurement, (board) PCBA processing, DIP through-hole soldering, PCBA testing,

cabinet assembly and One-stop electronic manufacturing services such as product testing, packaging, and logistics.

A2: With a variety of different product introduction experience, we have established a team of perfect ISO9001 quality system certification, including: human resources, marketing department, project management, engineering technology, PMC procurement, quality management, production, warehouse management And many other departments.

Q2, what information do we need to provide in order to get an accurate quote quickly?

A: The more detailed the product data and requirements are, the faster and more accurate the quotation will be, such as:

1.PCB manufacturing: Gerber files or PCB files

2.PCBA manufacturing: Gerber files, BOM bill of materials.

3.PCB requirements for sheet metal, thickness, copper thickness, tin spray, immersion gold, silk screen color, sheet color and other documents.

4.Comprehensive and detailed BOM bill of materials, including: part number, usage, specific specifications, parts manufacturers.

5.Replaceable parts, confirm approved spare parts.

6.PCBA IC pre-programming, providing software burning test version, test method.

7.PCBA or product assembly requirements, providing specific executable files.

8.If plastic, metal, cable, packaging, etc. are required, a document drawing that can be produced is required.

9.For other special requirements, a schematic document is required.

Q3, what is the minimum requirement for the order?

A: We support customers to arrange the order quantity according to their own needs. There is no minimum quantity limit.

Of course, the more orders, the more competitive the price competition.

Q4, How long is your order production time?

A: According to the complexity and simplicity of the product, when the parts are ready, we need 3-10 working days to prepare all the components.

Q5, can we visit your factory?

A: Our production facilities are always welcomed by customers. Please call us at +086-0755-27780875

or Email: marketing001 at meizenta.com. We will make an appointment for you to visit the factory.