- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depends on customer's need

-

Weight:

-

1200 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

Customized

-

Product name:

-

Milk processing equipments

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certificate:

-

ISO9001:2008/HACCP/CMP

-

Material:

-

SUS304/316L

-

Energy consumption:

-

Low consumption

-

Package material:

-

Pouches, paper, box, glass bottle

-

Application:

-

Milk, yogurt etc.

-

Packing:

-

Wodoen Case

-

Processing:

-

Baked Snacks Food Machine

-

Certification:

-

ISO9001:2008/HACCP/GMP

Quick Details

-

Machinery Capacity:

-

1T/H~50T/H

-

Brand Name:

-

Beyond

-

Year:

-

2024

-

Dimension(L*W*H):

-

Depends on customer's need

-

Weight:

-

1200 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

Customized

-

Product name:

-

Milk processing equipments

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certificate:

-

ISO9001:2008/HACCP/CMP

-

Material:

-

SUS304/316L

-

Energy consumption:

-

Low consumption

-

Package material:

-

Pouches, paper, box, glass bottle

-

Application:

-

Milk, yogurt etc.

-

Packing:

-

Wodoen Case

-

Processing:

-

Baked Snacks Food Machine

-

Certification:

-

ISO9001:2008/HACCP/GMP

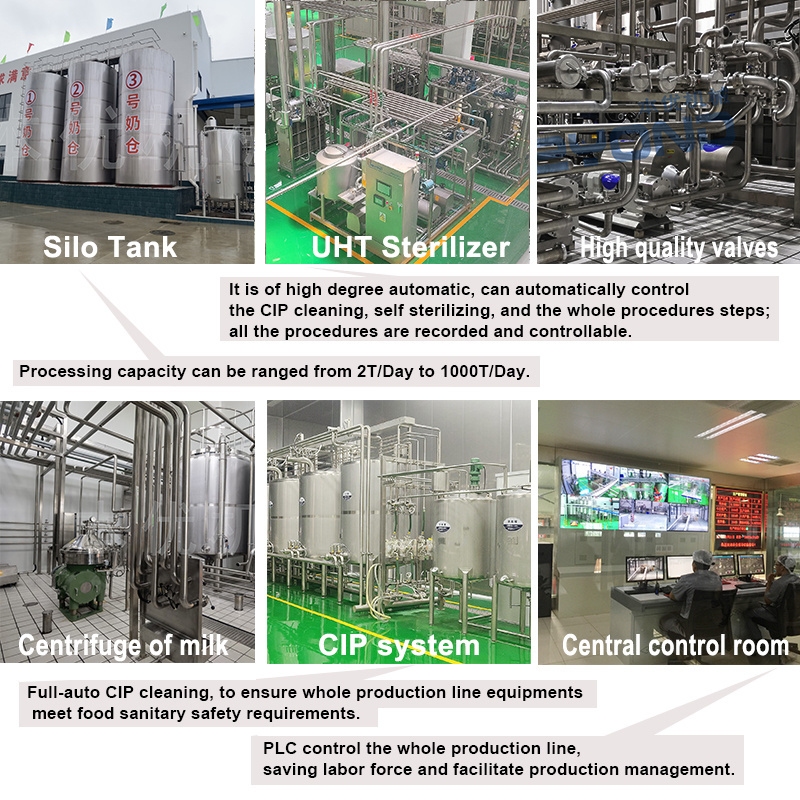

Small milk production line for making fresh milk UHT flavor milk and other dairy beverages

A small milk production line typically refers to a compact and relatively simple set of machinery and equipment designed for the processing and packaging of milk in smaller quantities compared to large-scale industrial dairy plants.

This kind of production line usually includes several stages:

1.Receiving and Pre-Treatment: Starting with the reception of raw milk from local farmers or storage tanks. Raw milk is filtered and may go through preliminary treatments like cooling to maintain freshness and inhibit bacterial growth.

2. Standardization: Ensuring that the milk has a consistent fat content by adjusting it to meet specific standards.

3. Pasteurization: Heating the milk to a high enough temperature (usually around 72°C for 15 seconds or higher for longer periods) to kill harmful pathogens without significantly altering its taste or nutritional value.

4. Homogenization: A process where milk is forced through a narrow valve at high pressure, breaking down fat globules into smaller sizes to prevent cream separation.

5. Filling and Packaging: The pasteurized and homogenized milk is then filled into bottles or cartons using automated filling machines, followed by sealing and labeling.

6. Cooling and Storage: The packaged milk products are cooled rapidly and stored in refrigerated conditions until they're ready for distribution.

7. Quality Control: Throughout the entire process, there are quality control checks to ensure the milk meets safety and hygiene standards.Small milk production lines are suitable for small dairy farms, rural cooperatives, or businesses starting out in the dairy industry.

They can be customized according to production capacity, available space, and budget constraints. Modern small-scale milk processing units often leverage technology to improve efficiency and product quality while maintaining a hygienic environment.

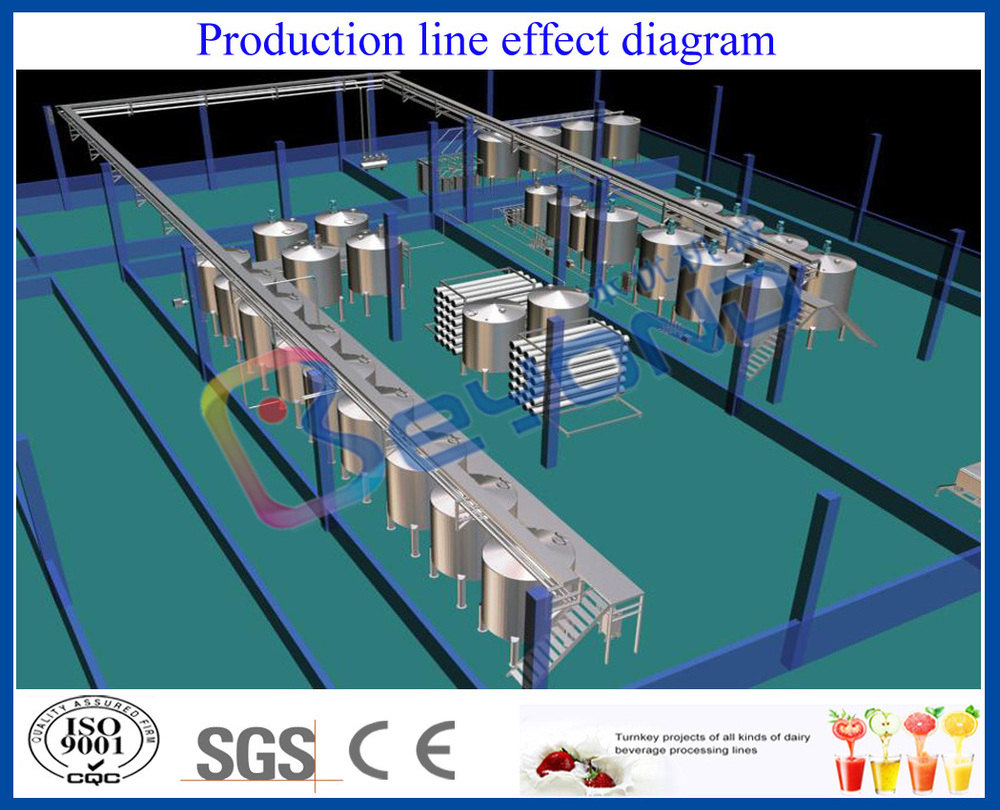

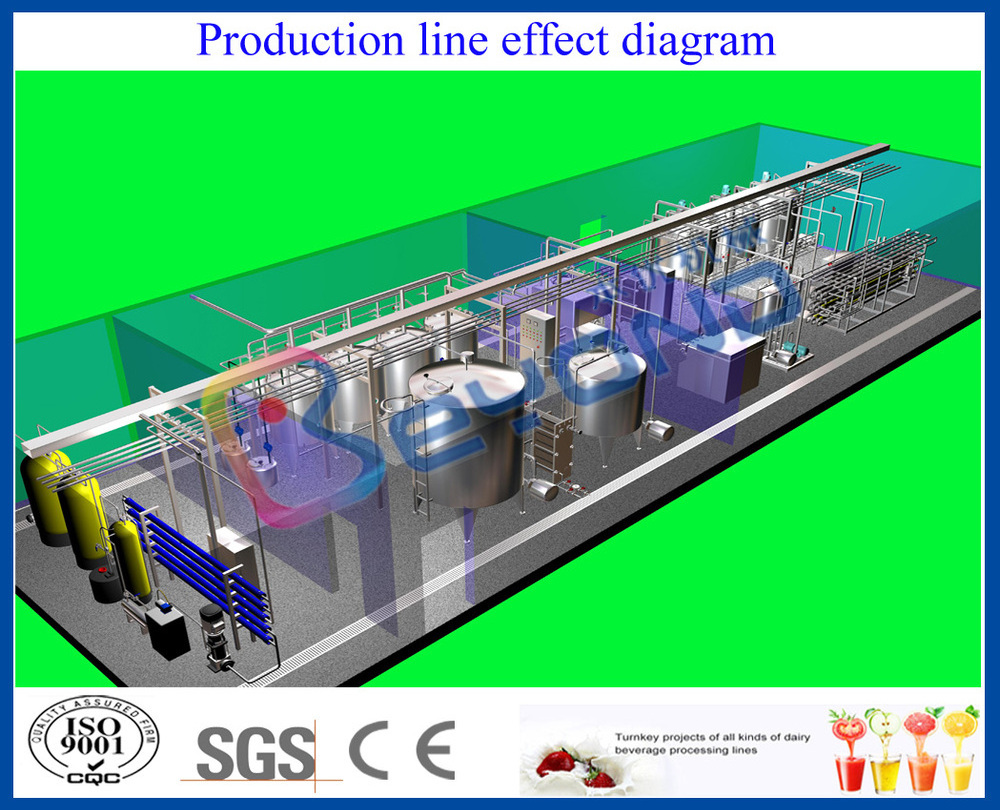

Processing flow diagram of milk processing equipments

Product Highlights

Milk processing equipments project photos

Equipment list sample of milk processing equipments

| Equipment list of milk processing equipments | |||

| No. | Name | Size | Main parameter |

| 1 | Milk reception and storage unit | ||

| 2 | Milk acceptor | 300L | SUS304 stainless steel, single layer, CIP spraying ball |

| 3 | Milk pump | 3T/H | SUS304, p ump lift 24m, h ard alloy mechanical seal, i nner shell mirror polished |

| 4 | Single piping filter | 3T/H | SUS304, single pipe, stainless steal filter element of 100 mesh |

| 5 | Milk storage tank | 1000L | SUS304, heat insulated, dimple pad jacket, vertical agitator, CIP spraying ball, breather valve, digital show thermometer, sampling point |

| 6 | Milk pump | 3T/H | SUS304, p ump lift 24m, h ard alloy mechanical seal, i nner shell mirror polished |

| 7 | Blending unit | ||

| 8 | Storage tank | 500L | SUS304, heat insulated, dimple pad jacket, vertical agitator, CIP spraying ball, breather valve, digital show thermometer, sampling point |

| 9 | Milk pump | 3T/H | SUS304, p ump lift 24m, h ard alloy mechanical seal, i nner shell mirror polished |

| 10 | Single piping filter | 3T/H | SUS304, single, stainless steal filter element of 100 mesh |

| 11 | Plate-type exchanger | 1.5T/H | SUS304, double pipes |

| 12 | High pressure homogenizer | 500L/H | 40MPa |

| 13 | Cream separtor unit | ||

| 14 | Milk separator | 500L/H | The content of dried skim milk ( % ) <0.03, the speed of rotator is 8000rpm |

| 15 | Buffer container | 100L | SUS304, with a cover, single layer |

| 16 | Buffer & cooling container | 100L | SUS304, with a cover, single layer |

| 17 | Milk pump | 3T/H | SUS304, with a cover, heat insulated, dimple pad jackets |

| 18 | Butter churner | 100L | SUS304 |

| 19 | Yogurt storage, ferment and filling unit | ||

| 20 | Temporary and ferment storage tanks | 500L | SUS304, heat insulated, dimple pad jacket, vertical agitator, CIP spraying ball, breather valve, digital show thermometer, sampling point |

| 21 | Milk pump | 3T/H | SUS304, p ump lift 24m, h ard alloy mechanical seal, i nner shell mirror polished |

| 22 | Rotor pump | 1T/H | SUS304, h ard alloy mechanical seal, adjustment speed by manual |

| 23 | Plastic pouch filling machine | ||

| 24 | Plastic cup-shaped filling machine | ||

| 25 | CIP system unit | ||

| 26 | Manual CIP system | 3×500L | SUS304, single clening circulation, with CIP pump of connected tanks |

| 27 | CIP return pump | 10T/H | SUS304, pump lift 24m ,hard alloy mechanical seal, inner shell mirror polished |

| 28 | Power system unit | ||

| 29 | Cold water equipment | 7000 kcale per hour, air cooling refrigeration | |

| 30 | Hot water boiler | 1000Kg/h, outlet temperature is 90 °C | |

| 31 | Installation system | Stainless steel piping system,power piping system, electric controlling box, electric installation material, installation and commissioning | |

Pre sales services

Post sales services

1.

Equipment warranty period

: We provide a one-year free warranty service for mechanical equipment. If any non-human caused problems occur during the warranty period, we will provide free repair or replacement services.

2.

Maintenance and upkeep services

: We provide regular or irregular equipment maintenance and upkeep services to ensure the normal operation of the equipment. We will provide 24-hour online technical support services.

3.

Accessory supply

: We guarantee to provide original factory accessories in a timely manner in case of equipment damage or replacement of parts.

4.

Training services

: In order to enable customers to effectively operate and maintain equipment, we will provide equipment operation and maintenance training.

5.

Installation and debugging

: We will provide equipment installation and debugging services to ensure that the equipment is installed correctly and can operate normally.