- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Wow

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

9000*1000*1400mm

-

Weight:

-

4000 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Rain gutter forming machine

-

Main frame:

-

350H Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Cutting type:

-

Hydraulic Cutting

-

Control system:

-

PLC(imported Brand)

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Feature:

-

High Production Speed

-

Color:

-

Customized Color

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Wow

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

9000*1000*1400mm

-

Weight:

-

4000 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Rain gutter forming machine

-

Main frame:

-

350H Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Cutting type:

-

Hydraulic Cutting

-

Control system:

-

PLC(imported Brand)

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Feature:

-

High Production Speed

-

Color:

-

Customized Color

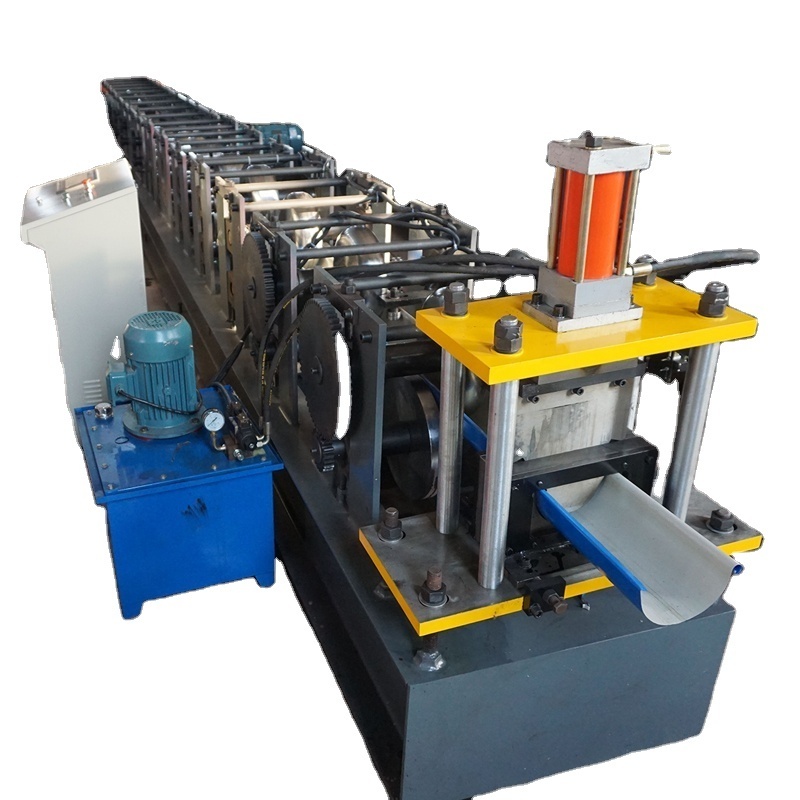

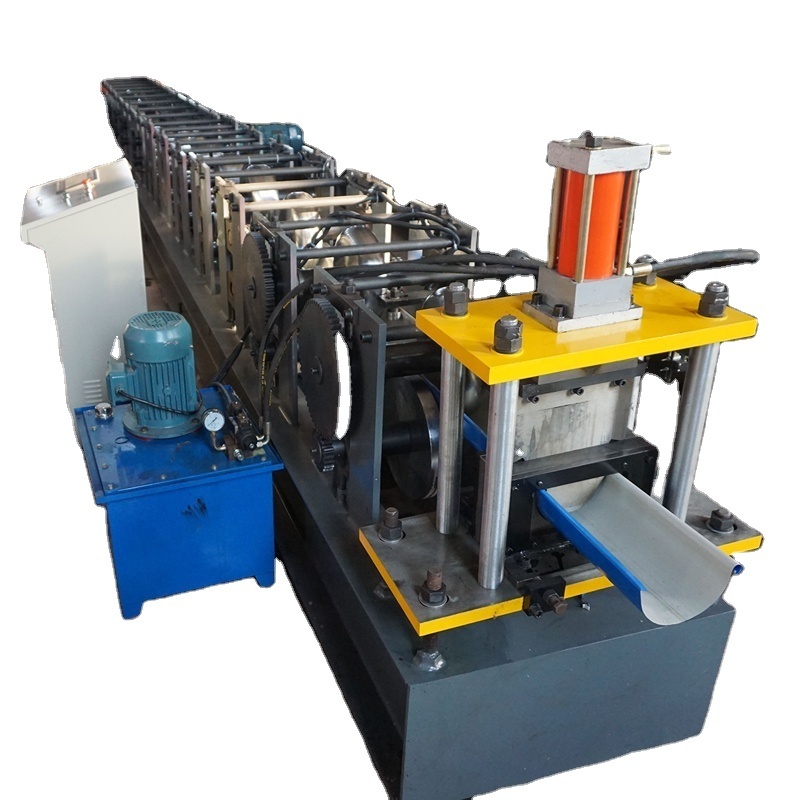

2024 New Automatic Cutting Rain Gutter Wayer Downpipe Roll Forming Machine

Rain Gutter R oll F orming M achine can form rain gutter profiles according to customer’s requirement . The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it can realize the continuous automatically production. Therefore, it is really a new type of energy-saving and high-effective equipment for metal rain gutters.

Our Advantages:

Perfect Quality

High Productivity

Low Consumption

One-Stop Service

Long Life Maintance

Product Pictures:

Main Parameter: ( All technical parameters can be changed,according to customer's need.)

|

Product Name |

Water Rain Gutter Roll Forming Machine |

|

Suitable material |

Color steel sheet , galvanized steel sheet,aluminum sheet |

|

Installation Dimension (L*W*H): |

9 m*1m*1. 4 m |

|

Main motor power |

4 KW with Cycloidal reducer |

|

Hydraulic station power |

4KW |

|

Hydraulic oil pump |

CB-E 310 |

|

Thickness of material |

0.3mm~0.8mm |

|

Diameter of principal axis |

Φ70-90mm |

|

Material expand width |

700 mm |

|

Electric tension |

380V 3phase 50HZ or as the customer's requirements |

|

Material of roller |

High grade 45# forged steel plated with hard chrome plating |

|

Controlling system |

PLC |

|

Processing speed |

3 - 1 5m/min |

|

Processing precision within |

1.00mm (depend on design) |

|

Material of cutting blade |

Cr12 mould steel with quenched treatment |

|

Kind of drive |

0.6 inch chain link bearing model 6210 |

|

Roller station |

8-20 Rollers as drawing |

|

Roller material |

high grade 45#steel; Cr12 quenching |

|

Leak frame load-bearing |

About 4 T |

Application Of the Profiles:

Other Products for Your Reference:

Standard export packing and delivery

Main body of roll forming machine and decoiler is nude packing

.

Rollers, shafts, PLC, pump and cutter are packed with

wooden frame.

We have professional technicians for loading to make sure machine has no damage.

Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you!