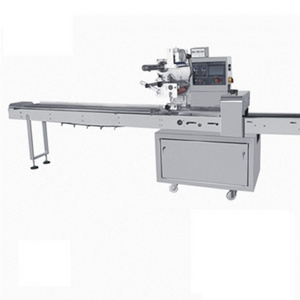

This machine is specially developed and manufactured by our scientific research personnel for a second packing of

aluminium-plastic plate in the industry, this upgrading the damp proof performance of

the packed aluminium-plastic plate and keeping the away from light. This machine adopts PLC programmable controller to program operation of the whole machine

aluminium-plastic plate in the industry, this upgrading the damp proof performance of

the packed aluminium-plastic plate and keeping the away from light. This machine adopts PLC programmable controller to program operation of the whole machine

and it is equipped with number printing

lot No. of production, production Date and Term of Validity, etc. on the outer package during packing process. Our scientific research personnel has also designed a

kind of automatic feeder suitable for aluminium-plastic tablet of various specifications, The apparatus of eliminate

the pressed and bad plate. Raise the automaticity of the machine, carry on flow Production. Each Performance figure met

the speeification requirements of GMP.