- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

IPC, Piezoelectric ceramics

Quick Details

-

Place of Origin:

-

GUA

-

Brand Name:

-

Argotec

-

Weight (KG):

-

500

-

Core Components:

-

IPC, Piezoelectric ceramics

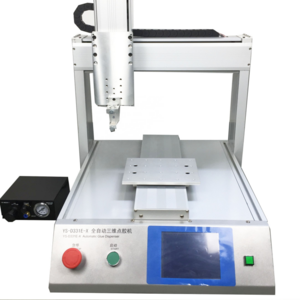

The AI Series Inline Dispensing Equipments utilize a compact mechanical layout. Different configurations such as ballscrew or linear direct drive motion system are available. Different applicators such as pneumatic or piezo-electric jet valves, screw valves, etc. can be installed to fulfill a large diversity of complex process requirements.

Features:

- High performance, high precision

- Integrated structural design yielding a compact layout

- High-quality core components to ensure reliability

- Long product lifetime and low cost of maintenance

- Powerful motion, vision, and software control systems to meet different production needs

- High performance, high precision

- Integrated structural design yielding a compact layout

- High-quality core components to ensure reliability

- Long product lifetime and low cost of maintenance

- Powerful motion, vision, and software control systems to meet different production needs

Multiple Configurations

- A comprehensive portfolio of hardware configurations are available for handling a multiplicity of production dimensions

- Dual-valve, dual-conveyor, three-sectioned conveyor, substrate heating, tilted dispensing, auto weighing, etc.

- Common-platform modular design approach allows for fast installation of different functional modules

- A comprehensive portfolio of hardware configurations are available for handling a multiplicity of production dimensions

- Dual-valve, dual-conveyor, three-sectioned conveyor, substrate heating, tilted dispensing, auto weighing, etc.

- Common-platform modular design approach allows for fast installation of different functional modules

Features:

- Non-contact dispensing:

Pneumatic and piezo-electric jetting

- High speeds:

pneumatic: up to 280 dots/s

piezo-electric: up to 1000 dot/s

- Modular design: Ease of maintenance

- Low cost of maintenance:

minimum wear parts

core parts are made of very durable material

- High precision

minimum dot volume 2-3nL

minimum dot diameter 0.15mm

- Non-contact dispensing:

Pneumatic and piezo-electric jetting

- High speeds:

pneumatic: up to 280 dots/s

piezo-electric: up to 1000 dot/s

- Modular design: Ease of maintenance

- Low cost of maintenance:

minimum wear parts

core parts are made of very durable material

- High precision

minimum dot volume 2-3nL

minimum dot diameter 0.15mm

AI Series Functional Modules

Dual-Valve Configuration

- Synchronous Operation: Two valves operate simultaneously to increase throughput

- Asynchronous Operation: Two valves operate separately, may be used for different glues or different processes

Dual-Conveyor Configuration

- May be used for increasing throughput (improve dispense head utilization)

- May be used for two different products / processes

- One of the conveyors may be used for empty carrier retrieval

Substrate Heating

- Air blown heating, to improve fluid flow

- Different types of heater and multi-zone heating available

Tilted Head Dispensing

- Maximum +/- 45 degrees tilting

- Supports down to sub-0.3mm line width dispensing

Dual-Valve Configuration

- Synchronous Operation: Two valves operate simultaneously to increase throughput

- Asynchronous Operation: Two valves operate separately, may be used for different glues or different processes

Dual-Conveyor Configuration

- May be used for increasing throughput (improve dispense head utilization)

- May be used for two different products / processes

- One of the conveyors may be used for empty carrier retrieval

Substrate Heating

- Air blown heating, to improve fluid flow

- Different types of heater and multi-zone heating available

Tilted Head Dispensing

- Maximum +/- 45 degrees tilting

- Supports down to sub-0.3mm line width dispensing

|

Model

|

|

AI-630

|

AI-800

|

|

|

Effective travel

|

X axis

|

250mm

|

350mm

|

|

|

|

Y axis

|

450mm

|

500mm

|

|

|

|

Z axis

|

50mm

|

50mm

|

|

|

Transmission mode

|

|

Ball screw

|

Ball screw

|

|

|

Max. speed

|

|

X/Y:1000 mm/s; Z:500 mm/s

|

X/Y:1500 mm/s; Z:500 mm/s

|

|

|

Max. acceleration

|

|

1g(X/Y)

|

1.5g(X/Y)

|

|

|

positioning accuracy

|

|

±30μm@3σ(X,Y),±10μm@3σ(Z)

|

±20μm@3σ(X,Y),±10μm@3σ(Z)

|

|

|

Repeat accuracy

|

|

±15 μm@3σ(X,Y),±5μm@3σ(Z)

|

±10 μm@3σ(X,Y),±5μm@3σ(Z)

|

|

|

Maximum load

|

|

Z:3kg,Track:3kg

|

Z:3kg,Track:3kg

|

|

|

Track height

|

|

890mm~965mm

|

890mm~965mm

|

|

|

Min. substrate size

|

|

50mm x 50mm

|

50mm x 50mm

|

|

|

Substrate thickness range

|

|

0.5mm<T<8mm

|

0.5mm<T<8mm

|

|

|

Control System

|

|

IPC

|

IPC

|

|

|

Software function

|

|

Visual positioning and inspection, batch modification, array copy, automatic fillet, height detection, CAD import, Jet on the fly

|

Visual positioning and inspection, batch modification, array copy, automatic fillet, height detection, CAD import, Jet on the fly

|

|

|

Power

|

|

AC220V(±10%) / 50HZ / 1400W

|

AC220V(±10%) / 50HZ / 2400W

|

|

|

Size(without PC)

|

L

|

1200mm

|

1200mm

|

|

|

|

W

|

650mm

|

750mm

|

|

|

|

H

|

1500mm

|

1500mm

|

|

|

Weight

|

|

500kg

|

800kg

|

|

|

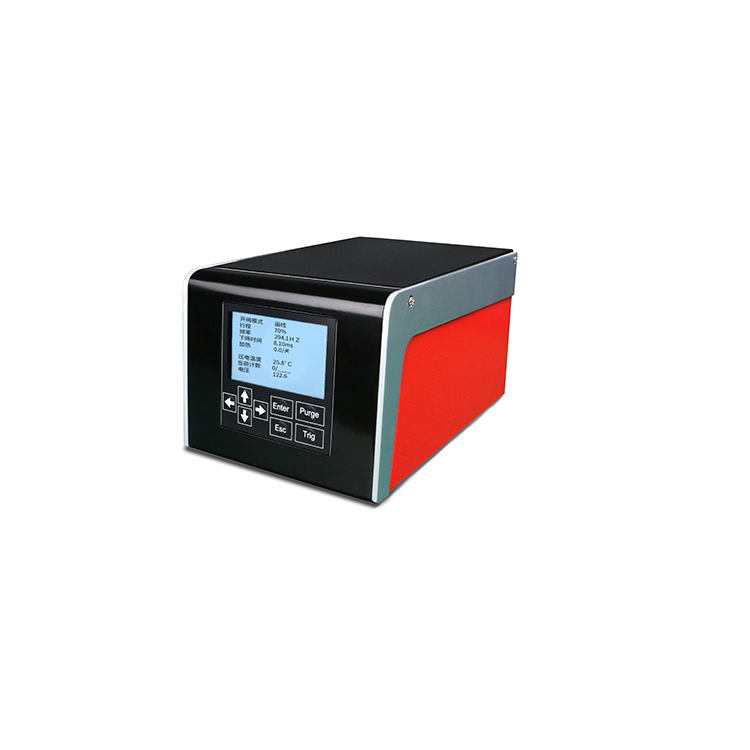

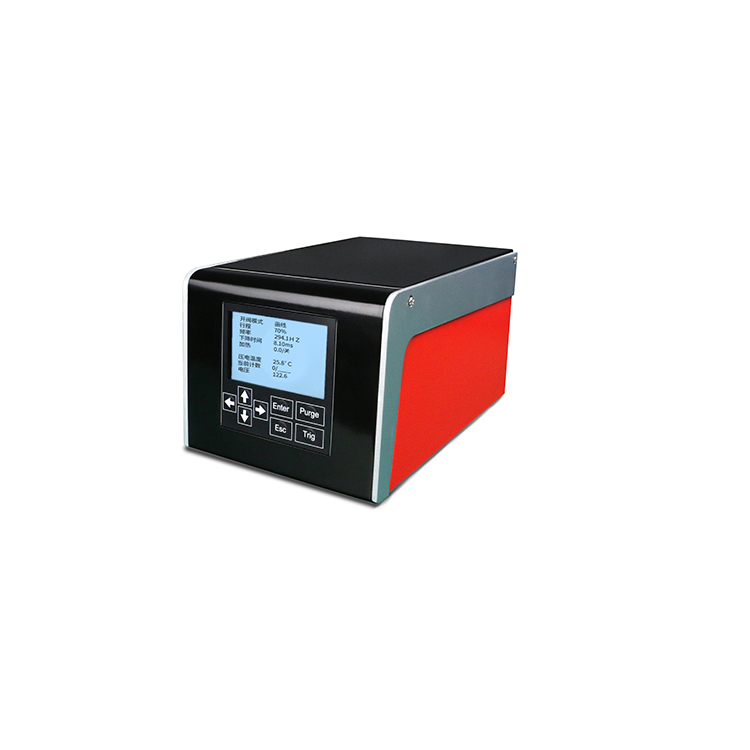

AV-8000

|

|

|

||

|

No.

|

Item

|

Data

|

||

|

1

|

Dimensions (LxDxH)

|

102mmx85mmx12mm

|

||

|

2

|

Net weight

|

0.42kg

|

||

|

3

|

The highest dispensing speed

|

500 points/sec

|

||

|

4

|

Minimum dispensing diameter

|

150μm

|

||

|

5

|

Nozzle diameter

|

0.05mm ~0.3mm

|

||

|

6

|

Feed air pressure

|

Max.0.5Mpa

|

||

|

AJC-53

|

|

|

||

|

1

|

Dimensions (LxDxH)

|

242mm×163mm×138 mm

|

||

|

2

|

Net weight

|

2.8kg

|

||

|

3

|

Input power

|

220V±10%/50HZ

|

||

|

4

|

Minimum valve opening/closing time

|

0.1ms

|

||

|

5

|

Minimum rise/fall time

|

0.1ms

|

||

|

6

|

Trigger input

|

24V pulse or short circuit signal

|

||

|

7

|

Communication interface

|

RS232

|

||

Typical applications

●

VCM

● Lens Fixing

● Lens Holder Adhesive Dispensing

● Flip-chip Underfill for Image Sensor

◆ Fingerprint recognition

● IC encapsulation

● Chip underfill

● Metal frame bonding

◆ Smart phone assembly

● Sealing for Cover Frame

● Chip Encapsulation and Underfill for FPC Assembly

◆ Acoustics Devices

● Ear Phone, Speaker and Microphone Assembly

● Speaker Frame and Membrane Assembly

● Coil Assembly

◆ MEMS

● Au Wire Encapsulation

● Solder Paste Acoustical Seal

◆ Vibration Motor

● Lids sealing

● Weld pad protection

● Lens Fixing

● Lens Holder Adhesive Dispensing

● Flip-chip Underfill for Image Sensor

◆ Fingerprint recognition

● IC encapsulation

● Chip underfill

● Metal frame bonding

◆ Smart phone assembly

● Sealing for Cover Frame

● Chip Encapsulation and Underfill for FPC Assembly

◆ Acoustics Devices

● Ear Phone, Speaker and Microphone Assembly

● Speaker Frame and Membrane Assembly

● Coil Assembly

◆ MEMS

● Au Wire Encapsulation

● Solder Paste Acoustical Seal

◆ Vibration Motor

● Lids sealing

● Weld pad protection

Hot Searches