- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

stainless steel woven net240423

-

Brand Name:

-

Weijia

-

Standard:

-

AISI.ASTM.EN.BS.GB.DIN.JIS.etc

-

Product name:

-

Stainless Seel Wire Rope

-

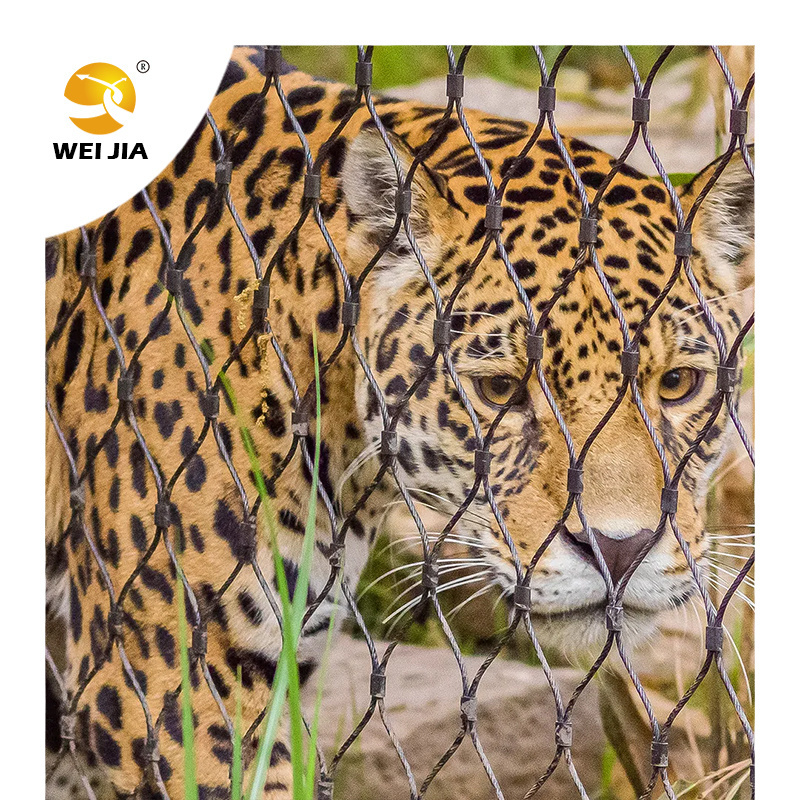

Usage:

-

Protection

-

MOQ:

-

10 Piece

-

Diameter:

-

1mm-5mm

-

Quality:

-

High Quaity

-

Sample:

-

Avaliable

-

Features:

-

High Corrosion Resistant

Quick Details

-

Material:

-

Galvanized Steel Wire

-

Type:

-

Rope Mesh

-

Application:

-

Protecting Mesh

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

stainless steel woven net240423

-

Brand Name:

-

Weijia

-

Standard:

-

AISI.ASTM.EN.BS.GB.DIN.JIS.etc

-

Product name:

-

Stainless Seel Wire Rope

-

Usage:

-

Protection

-

MOQ:

-

10 Piece

-

Diameter:

-

1mm-5mm

-

Quality:

-

High Quaity

-

Sample:

-

Avaliable

-

Features:

-

High Corrosion Resistant

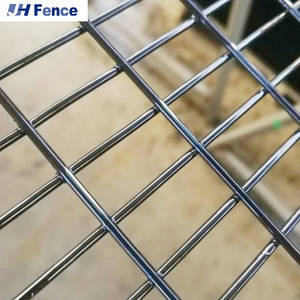

Stainless Steel Wire Rope: A Versatile Marvel of Engineering

Stainless steel wire rope stands as a testament to human ingenuity, embodying a perfect amalgamation of strength, durability, and versatility. Comprising multiple strands of stainless steel wire meticulously intertwined, this engineering marvel has revolutionized various industries with its unparalleled performance and reliability.

Unrivaled Durability and Corrosion Resistance

At the heart of stainless steel wire rope lies its exceptional resistance to rust and corrosion. Engineered to withstand the harshest of environments, from corrosive marine settings to challenging outdoor conditions, this material remains steadfast and reliable even in the face of adversity.

Exceptional Strength for Critical Applications

One of the defining characteristics of stainless steel wire rope is its remarkable tensile strength. Capable of bearing heavy loads with ease, it serves as the backbone for a myriad of critical applications, ranging from construction and maritime operations to industrial machinery rigging.

Enduring Longevity with Minimal Maintenance

With an extended lifespan and minimal maintenance requirements, stainless steel wire rope provides a cost-effective solution for long-term use. Its resilience to wear and tear ensures uninterrupted operations, making it an invaluable asset across industries where reliability is paramount.

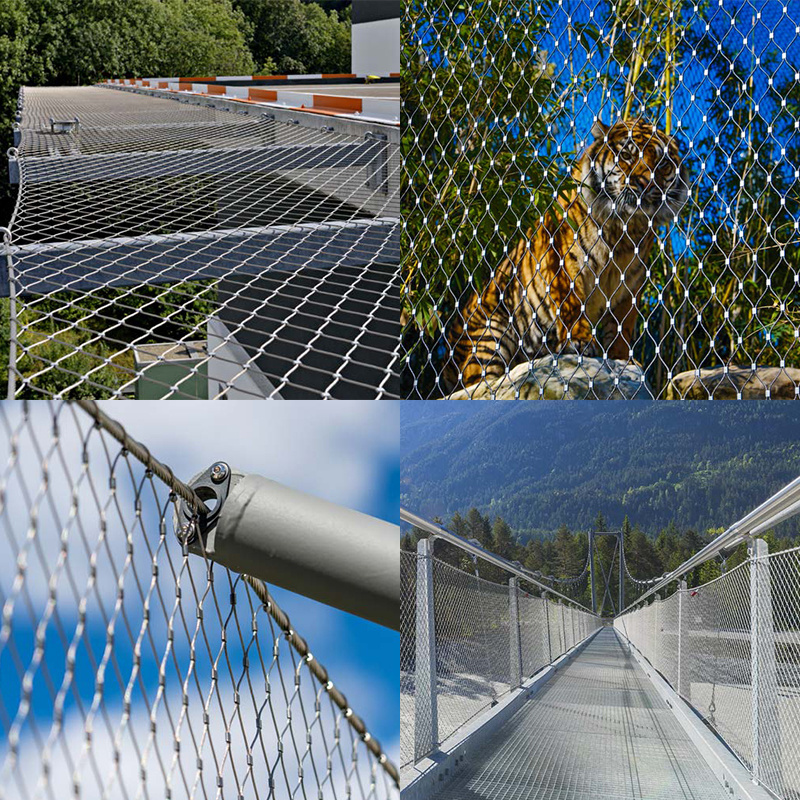

Versatility Across Industries and Applications

The versatility of stainless steel wire rope knows no bounds. From lifting and rigging in construction sites to mooring lines on maritime vessels, its adaptability enables seamless integration into various applications, enhancing operational efficiency and safety standards.

Flexibility for Dynamic Configurations

Despite its robust construction, stainless steel wire rope retains a remarkable degree of flexibility. This inherent quality allows it to conform to intricate configurations and adapt to dynamic operational requirements, ensuring optimal performance in diverse environments.

Common Locations of Deployment

Stainless steel wire rope finds widespread use across a multitude of locations, including construction sites, marinas, industrial facilities, bridges, and recreational areas. Its ubiquity underscores its indispensable role in supporting critical infrastructure and leisure amenities alike.

Specifications

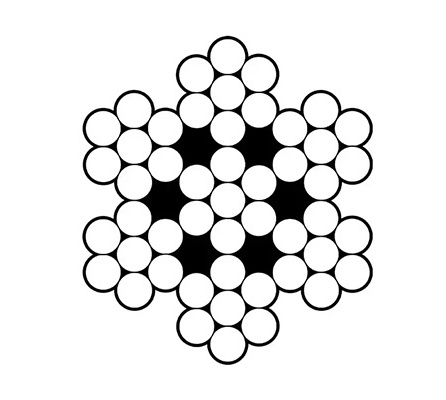

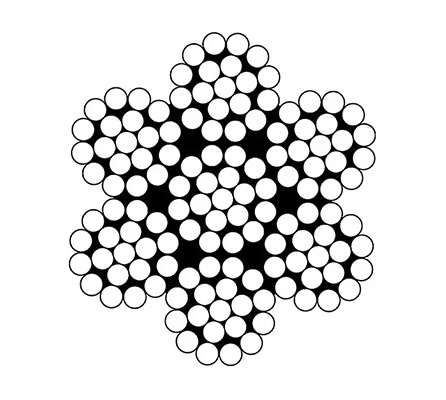

7 × 7 Construction Wire

The 7x7 wire rope, composed of 7 strands with 7 wires each.

It boasts semi-rigid properties, offering greater resistance to bending compared to the 7x19 variant. Primarily utilized for fixed rigging applications such as balustrading and safety barrier rails, its stability is ensured by even tension distribution across the entire mesh upon installation. The 7x7 wire rope finds limited application as a running or working rope. Known for its quality, this type of wire rope is indispensable in various industries including balustrading, shade structures and tensile membranes, marine, offshore oil & gas, mining, and cable net structures.

|

Wire Rope Diameter

(mm) |

Minimum Breaking Load

(kN)

|

Weight P/M

(Kg) |

Mesh Aperture

Width × Height (mm)

|

|

1.0

|

0.6

|

0.005

|

50 × 88

60 × 105

70 × 120

80 × 140

100 × 175

120 × 210

160 × 275

180 × 310

200 × 345

|

|

1.6

|

1.5

|

0.008

|

|

|

2.0

|

2.5

|

0.018

|

|

|

3.0

|

5.7

|

0.036

|

|

|

4.0

|

10.1

|

0.067

|

|

|

5.0

|

15.9

|

0.110

|

|

7 × 19 Construction Wire

The 7x19 wire rope comprised of 7 strands with 19 wires each, it is renowned for its flexibility, making it easily bendable for thimble eye terminations. This versatile stainless steel wire rope construction finds applications in fixed rigging as well as limited working rope scenarios, such as boat winches. Recognized for its superior quality, it is indispensable across various industries, including balustrade, shade structures and tensile membranes, marine, yacht rigging, steering cables, offshore oil & gas, mining, cable net structures, and irrigation bore pump cables.

|

Wire Rope Diameter

(mm)

|

Minimum Breaking Load

(kN)

|

Weight P/M

(Kg)

|

Mesh Aperture

Width × Height (mm)

|

|

2.5

|

4.3

|

0.026

|

90 × 156

100 × 173

120 × 208

150 × 260

|

|

3.0

|

5.8

|

0.039

|

|

|

3.2

|

6.9

|

0.045

|

|

|

3.5

|

7.5

|

0.054

|

|

|

4.0

|

10.6

|

0.069

|

|

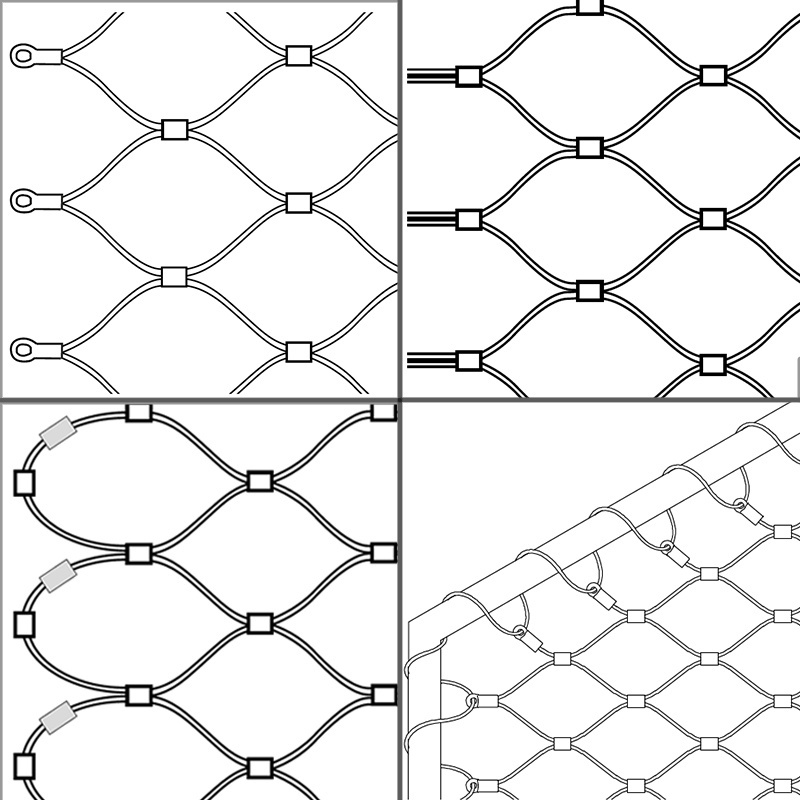

Mesh Diamond Direction

Horizontal Mesh Diamond

The mesh diamonds run horizontally across the building or frame. This direction may be chosen for architectural and visual reasons, as well as for ease of assembly and safety requirements. Additionally, horizontal mesh panels are often more economical, especially for longer panels.

Vertical Mesh Diamond

The mesh diamonds run vertically along the building or frame. This direction may also be chosen for architectural and visual reasons, along with assembly technique compatibility and safety requirements.

Diagonal Mesh Diamond

The mesh diamonds run diagonally in relation to the building or frame. This direction may be selected for its architectural appeal, assembly technique requirements, safety considerations, and structural requirements.

X-TEND Border Construction

This type of border construction utilizes standard eyelet design for quick and straightforward installation. Eyelets are used to secure the border to supporting structures or other surfaces, providing reliable anchor points.

Adjustable cable ends are featured on the sides to allow for on-site adjustments or adaptations. This design permits tweaking of the cable ends during installation to meet specific size or layout requirements.

This type of border construction employs a closed mesh design along with loose ferrules and connection ferrules. This specialized design is suitable for scenarios requiring additional support or customized installation requirements.

Standard Diagonal Eyelet Border Construction:

Standard diagonal installation method is used along with eyelets on the vertical borders. This design provides both structural integrity and maintains the unique appearance of diagonal mesh.

This design combines diagonal mesh with eyelets on the vertical borders, offering a convenient solution for securing diagonal mesh. The use of eyelets simplifies installation while ensuring reliability.

Variations In The Opening Angle

A smaller mesh opening angle results in increased mesh density, necessitating a greater amount of mesh to cover a given surface area compared to the standard 60° angle.

An opening angle of 60° for the mesh achieves optimal tension and serves as the mathematical foundation for determining the required quantity.

Accessories

Applications

Packaging

Our factory

FAQ

Q:Do you provide samples? is it free or extra?

A:Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: Are you trading company or manufacturer ?

A:

We are factory.

Q: How long is your delivery time?

A:

Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

quantity.

Q: How long per roll? What's the weight per roll?

A:500m/roll and the weight is about 25kg.

Hot Searches