- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Dixin

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

7000*1500*1400mm

-

Weight:

-

3000 kg

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Roof Sheet Forming Machine

-

Usage:

-

Galvanize Roof Sheet Machine

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Main frame:

-

350H Steel

-

Control system:

-

PLC(imported Brand)

-

Decoiler:

-

5T Manual Decoiler

-

Color of Machine:

-

Required Color

-

After-sales Service Provided:

-

Service Machinery Overseas

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Dixin

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

7000*1500*1400mm

-

Weight:

-

3000 kg

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Roof Sheet Forming Machine

-

Usage:

-

Galvanize Roof Sheet Machine

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Main frame:

-

350H Steel

-

Control system:

-

PLC(imported Brand)

-

Decoiler:

-

5T Manual Decoiler

-

Color of Machine:

-

Required Color

-

After-sales Service Provided:

-

Service Machinery Overseas

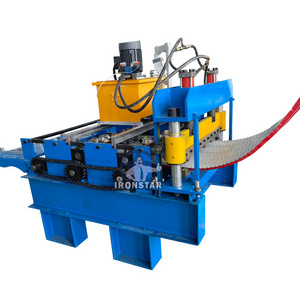

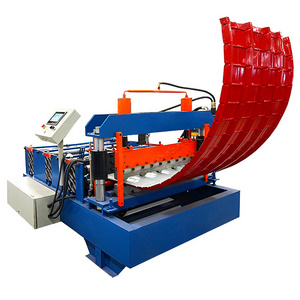

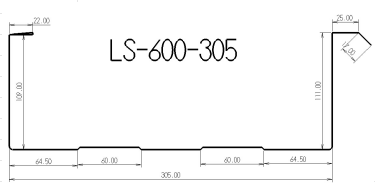

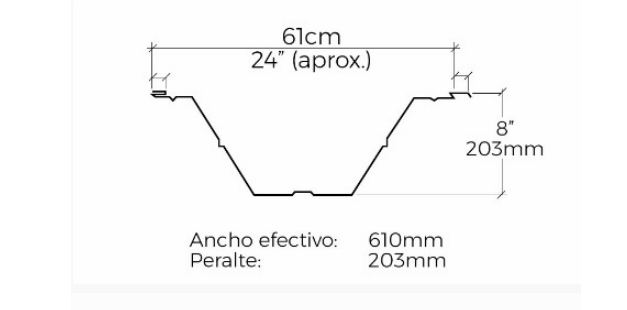

Products Description

Large span forming machine is to roll and press the colored steel sheet to be grooved shape, then to be arched shape with grooved section, finally to be sewed together by sewing machine. This kind of finished sheet will be used for lightweight steel roofing construction, The structure characteristics: rapid construction, low construction cost, low requirements of enviromental conditions, non-pollution, simple and lightness, high strenth. The seismic performance is good. Proffessionla line standardization of production. we can ensure the quality, modern design, elegant and practical.

Details Images

Working Flow

|

Machine

|

Parameters

|

|

|

|

|||

|

Products name

|

K Type Metal Roof Building Arch Sheet Roll Forming Machine

|

|

|

|

|||

|

Suitable to process

|

Color alu-zinc steel strips

|

|

|

|

|||

|

Control System

|

PLC control (Delta)

|

|

|

|

|||

|

Rollers

|

14 Rows plus leveling device

|

|

|

|

|||

|

Shaft Diameter

|

80 mm

|

|

|

|

|||

|

Thickness of the plate

|

0.3-0.8mm

|

|

|

|

|||

|

Hydraulic Pressure

|

10-12MPa

|

|

|

|

|||

|

Roller Standard

|

45#steel with chrome coating heat treatment

|

|

|

|

|||

|

Span

|

30m max.

|

|

|

|

|||

|

Cutter Blade matrial

|

Cr 12 High Grade Steel

|

|

|

|

|||

|

Main motor Power

|

18.5KW

|

|

|

|

|||

|

Voltage

|

380V 50Hz 3phases or customized

|

|

|

|

|||

|

Overall Size

|

11000kg

|

|

|

|

|||

|

Servo motor

|

3Kw

|

|

|

|

|||

|

Speed

|

Forming speed: 10-15m/min, Seaming speed:6m/min

|

|

|

|

|||

Manufacturing Technique

Manual Decoiler

1.Capacity: 5 tons

2. Coil inner diameter:450-550mm

3. Coil outer diameter: 1500mm

4. Coil width: 1250mm(as customers' profile drawing)

5. Structure: welded by the steel plates and profiled bar.

Roll Forming Machine

Feature: Ensure stability, precision and lifetime.

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Cutting Device

1. Hydraulic motor power: 3kw

2. Tolerance: 1mm

3. Blade mould material: GCr12MoV

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Hydraulic Station

1. Hydraulic motor Power: 3kw

2. Hydraulic oil: 46#

3. Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes. And three sets of electromagnetism valves.

Electric Control System

1. Control System: By PLC

2. PLC language: English and Chinese (or as required)

3. Function: Automatic length and quantity measurement

4. Feature: Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

Application

Hot Searches