- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

14.7*4.8*7.2(L*W*H

-

Weight:

-

17.8-50t

-

Warranty:

-

One Year Excluding Wearing Parts

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

ball mill

-

Product name:

-

grinding ball mill

-

Application:

-

Gold, copper, lead, chrome and mining

-

The Machines classification:

-

Ore Beneficiation

-

Color:

-

Iron Grey

-

Certification:

-

ISO9001:2008

Quick Details

-

Capacity(t/h):

-

0.5-50TPH

-

Place of Origin:

-

China

-

Brand Name:

-

Ascend

-

Dimension(L*W*H):

-

14.7*4.8*7.2(L*W*H

-

Weight:

-

17.8-50t

-

Warranty:

-

One Year Excluding Wearing Parts

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

ball mill

-

Product name:

-

grinding ball mill

-

Application:

-

Gold, copper, lead, chrome and mining

-

The Machines classification:

-

Ore Beneficiation

-

Color:

-

Iron Grey

-

Certification:

-

ISO9001:2008

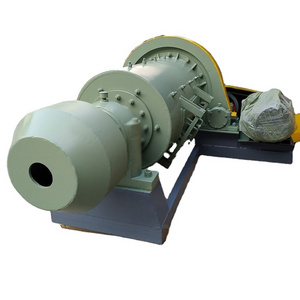

Mineral ball mill

Ball mill, also called grinding mill, ball grinding mill, is the key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc, with medium hardness.

According to different milling modes, the ball mills can be divided into dry and wet types. Due to different dishcarging methods, there are two types of ball mills: into-lattice type and over-flow type, or center-discharging type and side-discharging type. According to the different kinds of support, they can be devided into two types: bearing mill and bushing mill.

| Model |

Rotation

speed(r/m) |

Grind Media(ton) |

Feed size

(mm) |

Discharge size(mm) |

Capacity

(t/h) |

Motor

(KW) |

Weight

(ton) |

| 900x2100 | 38 | 1.5 | 0-150-150-150-200-200-200-250-250-250-250-250-250-250-250-250-250-250-25 | 0.074-0.4 | 0.5-2 | 15 | 3.9 |

| 900x2400 | 38 | 1.8 | 0.7-2.8 | 18.5 | 4.5 | ||

| 900x3000 | 38 | 2.5 | 0.8-3.5 | 22 | 5.0 | ||

| 1200x2400 | 32 | 3.8 | 0.9-4.8 | 30 | 9.2 | ||

| 1200x3000 | 32 | 4.5 | 1.2-5.6 | 37 | 11.5 | ||

| 1200x4500 | 30 | 5.5 | 1.5-6.0 | 55 | 13.6 | ||

| 1500x3000 | 27 | 7.0 | 2.5-6.5 | 75 | 15.0 | ||

| 1500x3500 | 27 | 8.5 | 3.0-8.2 | 75 | 15.6 | ||

| 1500x4500 | 27 | 11 | 4-10 | 95 | 21.0 | ||

| 1500x5700 | 27 | 12 | 4-13 | 110 | 23.5 | ||

| 1830x3000 | 24 | 12 | 5-15 | 130 | 31.0 | ||

| 1830x3600 | 24 | 13 | 5-16 | 130 | 32.0 | ||

| 1830x4500 | 24 | 14 | 5-18 | 155 | 33.5 | ||

| 1830x7000 | 24 | 21 | 6-20 | 210 | 36.0 | ||

| 2100x3000 | 24 | 18 | 7-26 | 210 | 38.0 | ||

| 2100x3600 | 24 | 21 | 7-35 | 215 | 39.5 | ||

| 2100x4500 | 24 | 26 | 8-42 | 245 | 43.5 | ||

| 2400x3000 | 21 | 23 | 8-60 | 285 | 55.0 |

Product details:

For ball mill, the main spare parts is steel balls, ball mill liners and grate plates. If the customer need the ball liners and grate plates, they can send us the drawing of liners and grate plates, we can cast for them in our casting factory. If you do not have the liner data,we can send our engineer to your site and scale

the liners, then we can make the drawing and cast the liner in our foundry factory for you.

Q1: Are you trading company or manufacturer?

A: We are factory.

Q2: What is your payment method?

A: 30% of total price should be paid by T/T as down payment; 70% balance payment should be paid by T/T before delivery.

Q3: What Information should customers give us, So that we can be able to provide you suitable quotation and service.

What minerals are you separating?

What's the maximum size of your raw minerals?

How much capacity do you need per hour for your project?