- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

230V, 380v, 440v

-

Power:

-

AS PER MODEL

-

Dimension(L*W*H):

-

AS PER MODEL

-

Weight (KG):

-

10000

-

Product name:

-

Rotary dryer

-

Spare parts:

-

Supplied at favorable price

-

Installation:

-

As per our engineer's guidance

-

Pre-sales Service:

-

Drying process and plant design

-

After-sales Service:

-

Lifelong

-

Price:

-

Competitive (manufacturer)

-

Factory Visit:

-

Invitation letter, round trip car pick up

Quick Details

-

Type:

-

Drum Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhongke

-

Voltage:

-

230V, 380v, 440v

-

Power:

-

AS PER MODEL

-

Dimension(L*W*H):

-

AS PER MODEL

-

Weight (KG):

-

10000

-

Product name:

-

Rotary dryer

-

Spare parts:

-

Supplied at favorable price

-

Installation:

-

As per our engineer's guidance

-

Pre-sales Service:

-

Drying process and plant design

-

After-sales Service:

-

Lifelong

-

Price:

-

Competitive (manufacturer)

-

Factory Visit:

-

Invitation letter, round trip car pick up

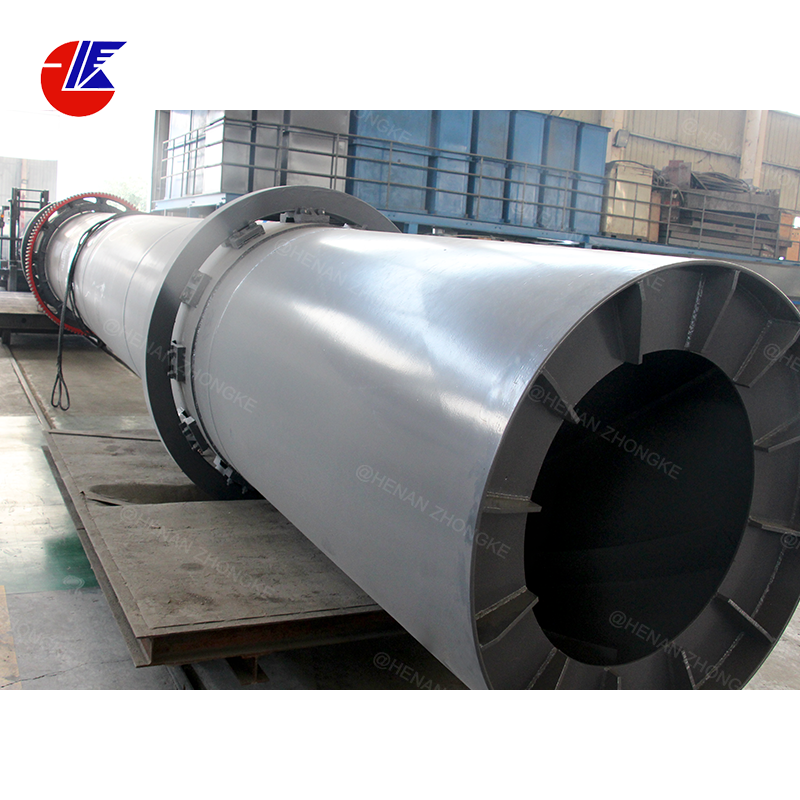

Product Show

Single drum dryer (rotary single drum dryer)

it is a drying machine used to dispose masses of materials.

Single drum dryer is widely used in the field of building materials, metallurgies, chemical industry, cement and so on. it can dry slag, coal powder, mining powder, clay, sand, limestone and so on. It is made into rotary body, lifting blade, driving device, supporting device etc. It adopt the reasonable operation parameters and it also reduce the coal and power consumption by more than 10- 15% increases the output by more than 10- 15% compared with the general dryers.

Performance Feature:

1.simple structure; 2 polishing produdtion; 3.high capacity; 4.low energy-consumption.

Working Principle:

The heat sources of the dryer is from the combustion train. Because of the tilting device of dryer, when the materials enter into the body from the feeding device, i will flow to the bottom end under the infuence of gravity, as the drier is in an inclined position. This process makes the material well-distributed in the body, then ensure the heat exchange with the heat wind. After repeated cycle with this process,the moisture content will be dried and discharged from the dryer.

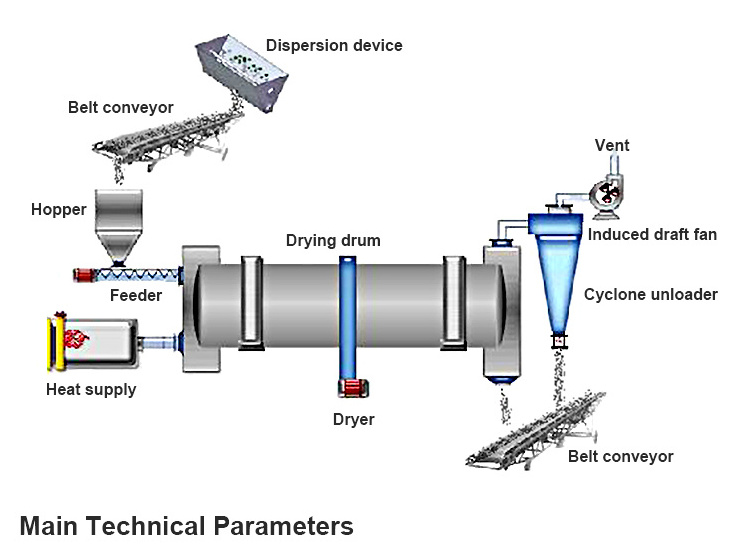

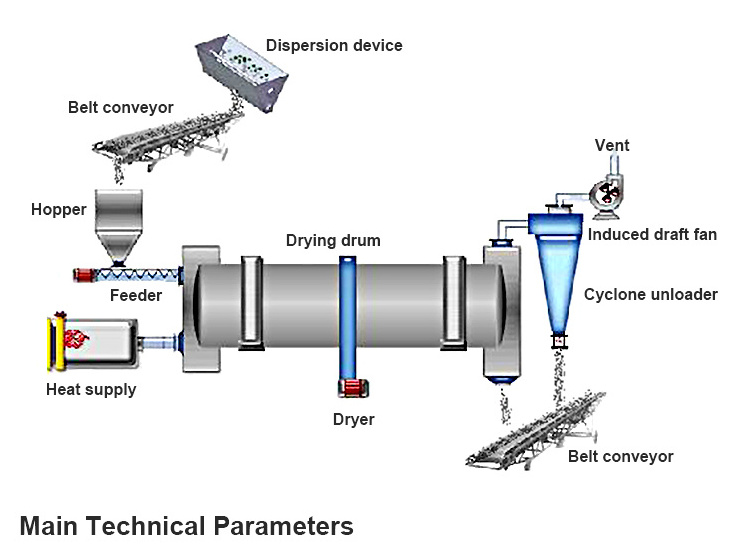

Schematic Diagram

|

Spec.(m)

|

Capacity(t/h)

|

Main motor

|

|

Main reducer

|

|

Weight(t)

|

||

|

|

|

Power(kw)

|

Model

|

Model

|

Speed ratio

|

|

||

|

Φ1.2×10

|

6-8

|

7.5

|

Y160M-6

|

ZL50-16-1

|

31.5

|

12.5

|

||

|

Φ1.5×12

|

8-12

|

15

|

Y180L-6

|

JZQ500-IlI-2F

|

31.5

|

16.5

|

||

|

Φ1.5×15

|

12-16

|

18.5

|

Y200L-6

|

JZQ500-Ill-2F

|

31.5

|

18

|

||

|

Φ1.8×12

|

18-20

|

18.5

|

Y200L-6

|

ZQ50-16ll-2

|

31.5

|

20

|

||

|

Φ2.2×12

|

22-28

|

22

|

Y160L-6

|

JZQ650-IlI

|

31.5

|

37.6

|

||

|

Φ2.2×14

|

26-30

|

22

|

Y160L-6

|

JZQ750-IlI

|

31.5

|

40

|

||

|

Φ2.4×14

|

30-35

|

30

|

Y250M-6

|

JzQ750-III

|

31.5

|

51

|

||

|

Φ2.4×18

|

35-40

|

37

|

Y250M-6

|

ZL85-13-1

|

27.16

|

54

|

||

|

Φ2.4×20

|

38-42

|

37

|

Y250M-6

|

ZL85-13-1

|

27.16

|

54.14

|

||

|

Φ2.8×20

|

43-50

|

45

|

Y280S-6

|

ZL85-13-1

|

27.16

|

71

|

||

|

Φ3x20

|

45-55

|

55

|

Y250M-4

|

ZL100-16-1

|

41.52

|

78

|

||

|

Φ3×25

|

58-70

|

75

|

YR280M-4

|

ZL100-16-1

|

41.52

|

93

|

||

|

Φ3.2×25

|

75-90

|

90

|

Y315M-6

|

ZSY315-22-ll

|

22.4

|

156

|

||

|

Φ3.6×25

|

95-110

|

160

|

Y355L1-4

|

ZSY500-35

|

35.5

|

170

|

||

|

Φ3.6×28

|

80-140

|

200

|

Y355L2-4

|

ZSY500-35

|

35.5

|

180

|

||

Three drum rotary dryer is mainly used for drying a certain humidity and size of granular materials, such as yellow sand used in dry powder and mortar, various specifications of sand used in a foundry industry blast, furnace slag used in building materials and cement industry, clay in a small size, small materials which have no chemical changes, resists high temperature and are with flyblown dust, used in chemical industry. In according with the request of materials and water in different industries, water in materials which are dried can be below 1-0.5%.

Working Principle:

1. Materials will be constantly lifted up by lifting boards, and scattered in spiral type to make hot exchange.

2. And then, material will be moved to middle layer of drum for countercurrent drying, and materials in middle layer of drum will be constantly lifted up by lifting boards. Materials in middle layer of drum can both full absorb heat generated by inner drum layer, and heat generated by middle drum layer, while extend drying time, so materials reached its driest state in this process.

3. Material can move to the outer drum layer from the middle drum layer, material reached the drying effect will be discharged fast along with hot air, while wet materials have not meet the drying effect can' t move quickly due to high weight, so wet material can get adequate drying to reach drying effect thus achieve to complete the drying process.

Schematic Diagram

|

Model

|

T/H

|

|

|

|

Coal consumpation

g/T Dry

|

Power(kw)

|

|||

|

|

Slag

|

Fly ash

|

Clay

|

Yellow sand

|

|

|

|||

|

Φ2.0×4

|

5-10

|

4

|

4-6

|

10-15

|

12-14

|

11

|

|||

|

Φ2.0×5

|

10-15

|

6

|

6-8

|

15-20

|

12-14

|

11

|

|||

|

Φ2.5×5

|

20-25

|

8

|

8-12

|

20-25

|

10-12

|

15

|

|||

|

Φ2.5×6

|

25-30

|

10

|

12-15

|

25-30

|

10-12

|

15

|

|||

|

Φ2.8×6

|

30-35

|

15

|

15-20

|

35-40

|

10-12

|

22

|

|||

|

Φ3.0×6

|

35-40

|

20

|

20-25

|

40-45

|

8-10

|

30

|

|||

|

Φ3.0×7

|

40-45

|

25

|

25-30

|

45-50

|

8-10

|

30

|

|||

|

Φ3.2×7

|

45-50

|

30

|

30-35

|

50-60

|

8-10

|

44

|

|||

|

Φ3.2×8

|

50-60

|

35-40

|

35-40

|

60-70

|

6-8

|

44

|

|||

|

Φ3.6×8

|

60-70

|

40-45

|

40-45

|

70-80

|

6-8

|

60

|

|||

|

Φ3.8×9

|

70-80

|

45-50

|

45-50

|

80-90

|

6-8

|

60

|

|||

|

Φ4.0×10

|

80-90

|

50-60

|

50-60

|

90-100

|

6-8

|

74

|

|||

Any change of technical data shall not be advised additianally.

Technology Introduction

The rotary dryer produced by Zhongke has the drying system equipment through technology innovation, which adopts the most advanced hydraulic catch wheel, high precision of measurement piston pump, flow speed control valve, and contact graphite piece of sealing device at home and abroad, In order to improve the degree of automation, dryer head adopts industrial TV watching fire, analog fluorescent screen for process flow, and drying adopts the infrared scanner, directly reflecting the drying situation in computer . All these new technology has a strong intuitive sense in use, easy to operate. Reliable and stable thermal condition improves the operation rate of the equipment. Compared with the same specification of equipment, the operation rate increases by 10%, the yield increases by 5%-10%, and the heat consumption decreases by 15%.

1.Cow dung

2.Chicken manure

3.Sawdust

4.Rice husk

1.Biomass

2.Vinasse

3.Sand

4.Sludge

1.Calcium ore

2.Chemical Iandustry

3.Building material

4.Calcite

Product details

Our products have the following six major features,so that we can lead

other manufacturers at home and abroad

Roller ring F

rame B

ig gear

Motor S

mall gear

Roller support

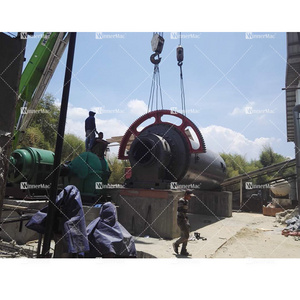

Installation Site

Hot Searches