- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/240/380V 50/60 Hz

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

535

-

After-sales Service Provided:

-

Video technical support

-

Product Name:

-

Continuous Stirred Tank Reactor

-

Contact Material:

-

SUS304/316 and carton steel

-

Heating method:

-

electric,steam,oil

-

Mixing Type:

-

Paddle Mixer

-

Color:

-

Custmer

-

Product type:

-

chemical reactor :Dyestuff, pesticide, oil

-

Jacket volume:

-

Customized

-

Volume:

-

50L-28000L

Quick Details

-

Capacity:

-

4589L, Custmer

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KEXINDA

-

Voltage:

-

220/240/380V 50/60 Hz

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

535

-

After-sales Service Provided:

-

Video technical support

-

Product Name:

-

Continuous Stirred Tank Reactor

-

Contact Material:

-

SUS304/316 and carton steel

-

Heating method:

-

electric,steam,oil

-

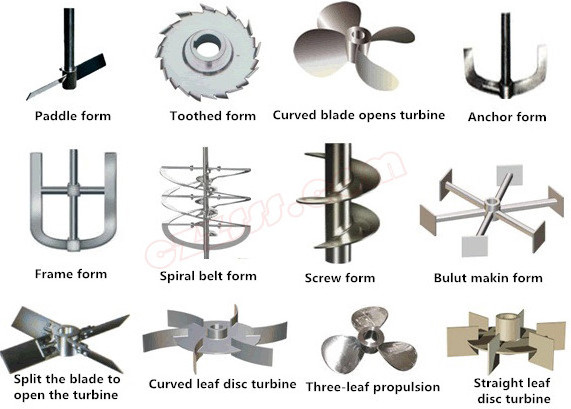

Mixing Type:

-

Paddle Mixer

-

Color:

-

Custmer

-

Product type:

-

chemical reactor :Dyestuff, pesticide, oil

-

Jacket volume:

-

Customized

-

Volume:

-

50L-28000L

|

liquid alkyd resin reactor/epoxy resin making machine/glue making equipment

|

Product Application

Stainless steel reactor is a new type of reaction equipment developed on the basis of absorbing domestic and foreign advanced technology. It has the characteristics of rapid heating, hightemperature resistance, corrosion resistance, hygienic, no environmental pollution, no need for automatic heating of boiler, easy to use and so on. Used in petroleum, chemical, rubber, pesticide, dyes, medicine, food, used to complete the curing, nitrification, hydrogenation, alkylation, polymerization, condensation and other process

Our factory can customize the workbench for your machine.

specification

Main Features

1.Material: a) kettle and cover: SS 304 , SS 316, carton steel , enamel or glass lined ; b) jacket: SS304 or carton steel

2.Heating way: Electric heating, oil heating, oil, water, steam heating. optional.

3. Structure type: Outer coil heating reactor, Inner coil heating reactor, Jacket heating reactor.

4. Jacketed type reaction kettle, coil pipe reaction still, electric heating reaction vessel, multi-function reactor,

5. Mechanical seal (vacuum) or packing seal.

6. Supply complete production line, as well as producing technology. Other related machines as kneader, disperser, blending machine etc. are available. Quality Assurance 50~50000L Chemical reactor.

7. We could do equipment according to your detail requirements.

Optional PLC control

The machine can be selected without explosion protection, the motor explosion-proof and the whole machine explosion-proof three options.

The motor can be selected from China Huiergy, Jiamusi explosion-proof motor, Siemens explosion-proof motor and other brands.

The equipment consists of a vertical condenser, a horizontal condenser, a reaction kettle, a water storage device and a fractionation column. It is a special equipment for producing unsaturated polyester resin. Unsaturated polyester resin equipment has reasonable design and advanced technology. It is the most ideal unsaturated resin production line in the domestic market. Users can order from our company according to their annual production capacity and technical requirements.

Finally, the above picture is for reference only.

As a machine

manufacturer

, we can offer you low prices and quality products.

Our machines can be

customized

, if you are interested in the product and would like to know more details, please contact me.