- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.7mm-1.2mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HRF

-

Voltage:

-

380V Or As Customize

-

Dimension(L*W*H):

-

45x5x3m

-

Weight:

-

5000 kg

-

Feeding width:

-

100-600mm

-

Keywords:

-

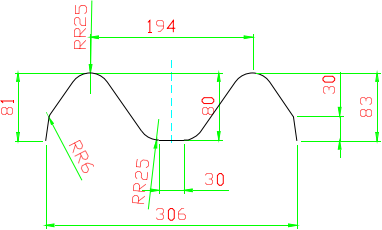

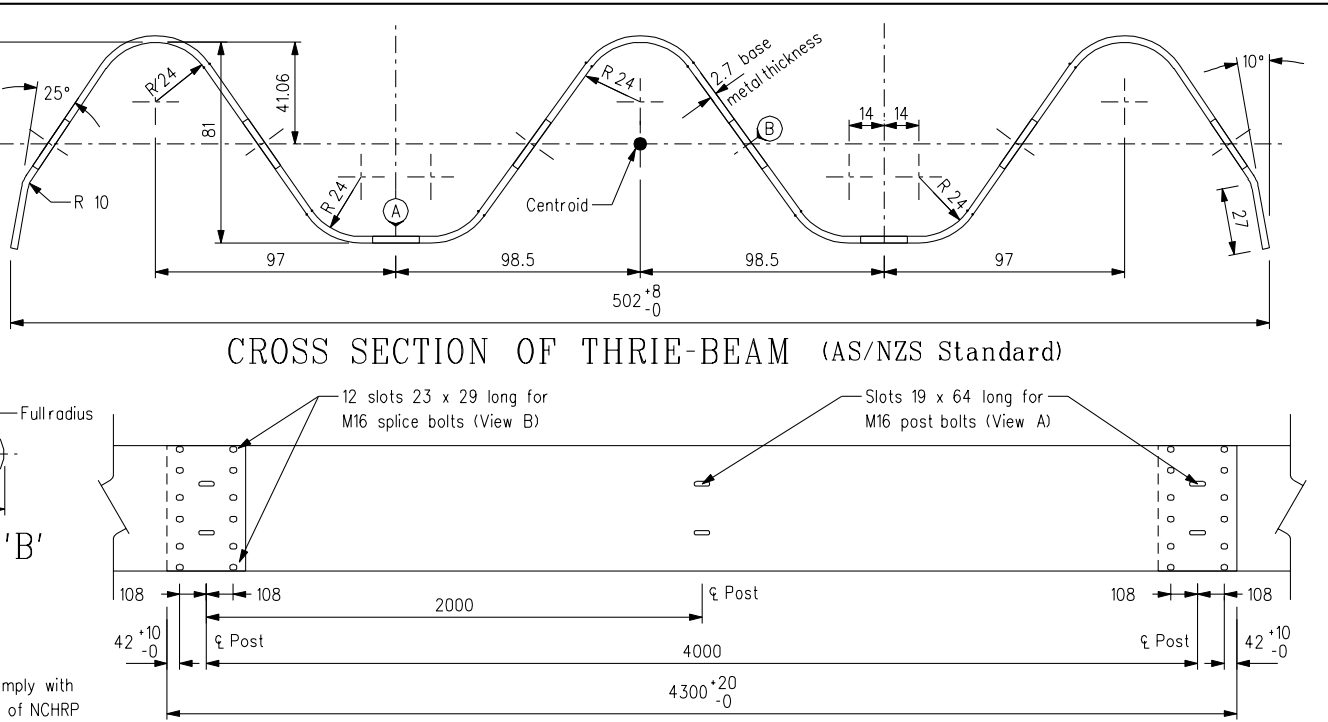

Two Corrugate Highway Guardrail Cold Roll Forming Machine

-

Material Thickness:

-

1.5-3.5mm

-

Control system:

-

automatic

-

Main Power:

-

15kw

-

forming station:

-

18

-

work speed:

-

15-20m/min

-

way of drive:

-

chain ,1 inch

-

Raw material:

-

PPGI

-

name:

-

Guard Rail Roof Panel Roll Forming Machine

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Glazed

-

Production Capacity:

-

100ft/min

-

Rolling thinckness:

-

0.7mm-1.2mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HRF

-

Voltage:

-

380V Or As Customize

-

Dimension(L*W*H):

-

45x5x3m

-

Weight:

-

5000 kg

-

Feeding width:

-

100-600mm

-

Keywords:

-

Two Corrugate Highway Guardrail Cold Roll Forming Machine

-

Material Thickness:

-

1.5-3.5mm

-

Control system:

-

automatic

-

Main Power:

-

15kw

-

forming station:

-

18

-

work speed:

-

15-20m/min

-

way of drive:

-

chain ,1 inch

-

Raw material:

-

PPGI

-

name:

-

Guard Rail Roof Panel Roll Forming Machine

|

NO.

|

Name

|

QTY

|

Remark

|

|

1

|

10T Coil car and

10T hydraulic decoiler |

1

1 |

1)Max 10T

2)Hydraulic inner expansion,expansion range:460-520mm.outer dia max1900mm 3)Coil width:max 800mm 4)Drive Motor:7.5kw 5)Hydraulic station motor:4kw |

|

3

|

Shovel head,guiding ,feeding Leveling

|

1 set

|

1) 9 rolls leveling(4+5rolls)

2)Leveling rolls dia 90mm 3)Leveling motor:5.5kw |

|

4

|

Servo-feeder system

|

1 set

|

1)Yaskawa servo-feeder

2)3kw plus reducer 3)PLC control cabinet |

|

5 |

Holes punching |

3 sets |

1)We adopt 4 column hydraulic press to punch the holes.

2)Hydraulic punching power:22kw 3)Mould material Cr12Mov,HR58-62 4)Mould qty: 3 sets |

|

6

|

cutting system

|

1 set

|

1)We will use hydraulic pre-cut

2)Cutting blade material:Cr12Mov,HRC58-62 3)Cutting power:30kw |

|

7

|

Motorized transmissioning belt

|

1 set

|

1) transmissioning belt length: 7m

2) Motor:2-1.5kw |

|

8

|

Roll forming machine

|

1 set

|

1)heavy-stands structure with gearbox chain drive

2)19 forming stands 3)44KW motor made in China 4)Rollers materials:SKD-11 HRC60 5)Shaft diameter:105mm |

|

9

|

Motorized transmissioning table

|

7m

|

1)Steel frame with Rollers

2)Max length:7m 3)Motor:2-3kw |

|

10

|

Electric control panel

|

1 set

|

1)1 set control panel for main forming machine

2)Siemens PlC made in Germany 3)Omron encoder made in Japan 4)Yaskawa inverter made in Japan 5) 1 set of control cabinet for servo-feeder |

|

11

|

Hydraulic system

|

1 set

|

1)1 set of hydraulic station for main forming machine cutting and holes punching

3)1 set of hydraulic station for hydraulic decoiler |

|

12

|

Cooling system

|

|

Water cooling system to be added and the whole water can be circulated in a closed pipeline.

|

5T Hydraulic Decoiler - Leveling - Servo Feeding - Punching Press - Forming Machine - Hydraulic Cutting - Run out Table

Hot Searches