- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TS-800/1200/1600/1800/2000

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

6000*2500*4000mm

-

Year:

-

2024

-

Weight (KG):

-

25000 kg

-

Power (kW):

-

250kw

-

Type:

-

Tire Recycling Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Waste Rubber Tyre Recycle Machine

-

capacity:

-

500kg-3000kg/h

-

feeding material:

-

waste tires

-

final product:

-

rubber blocks, rubber granules, rubber powder

-

Shippment:

-

By sea

-

Application:

-

Rubber Processing Machinery

-

Advantage:

-

long service time

-

Key word:

-

tire recycle

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

hvst

-

Marketing Type:

-

New Product 2024

-

Model Number:

-

TS-800/1200/1600/1800/2000

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

6000*2500*4000mm

-

Year:

-

2024

-

Weight (KG):

-

25000 kg

-

Power (kW):

-

250kw

-

Type:

-

Tire Recycling Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Waste Rubber Tyre Recycle Machine

-

capacity:

-

500kg-3000kg/h

-

feeding material:

-

waste tires

-

final product:

-

rubber blocks, rubber granules, rubber powder

-

Shippment:

-

By sea

-

Application:

-

Rubber Processing Machinery

-

Advantage:

-

long service time

-

Key word:

-

tire recycle

Product Description

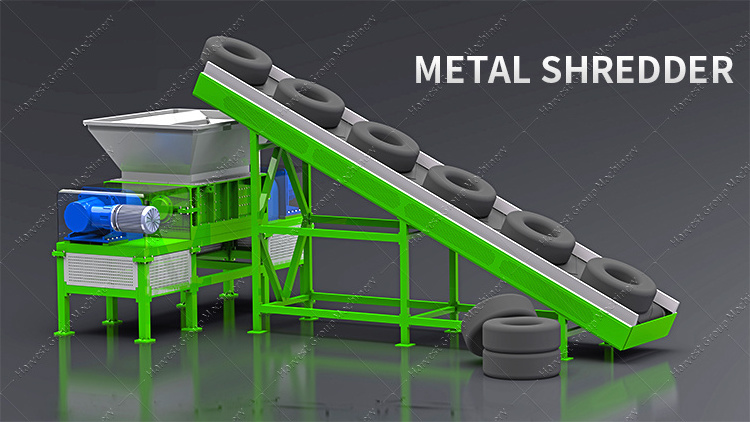

Two shaft shredders is a kind of industrial shredder specially designed for metal scraps, with low speed, high torque, minimum noise and power consumption, but high productive rate.

All the shredder blades thickness ranges from 25mm-152mm depending on the raw material and final size, while capacity ranges from 1~30 tons per hour.

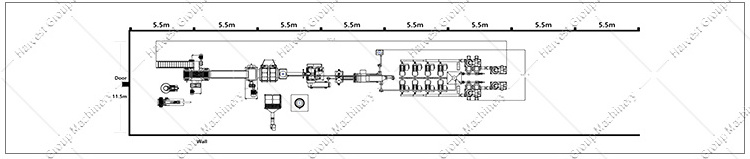

1.Provide the floor space and size required for recycling machine.

2.Provide the complete recycling line layout and its 3D drawing

3.After machine reach the customer's working site, We will assemble the main parts, then mark all the joint parts and send videos to guide the installation and training

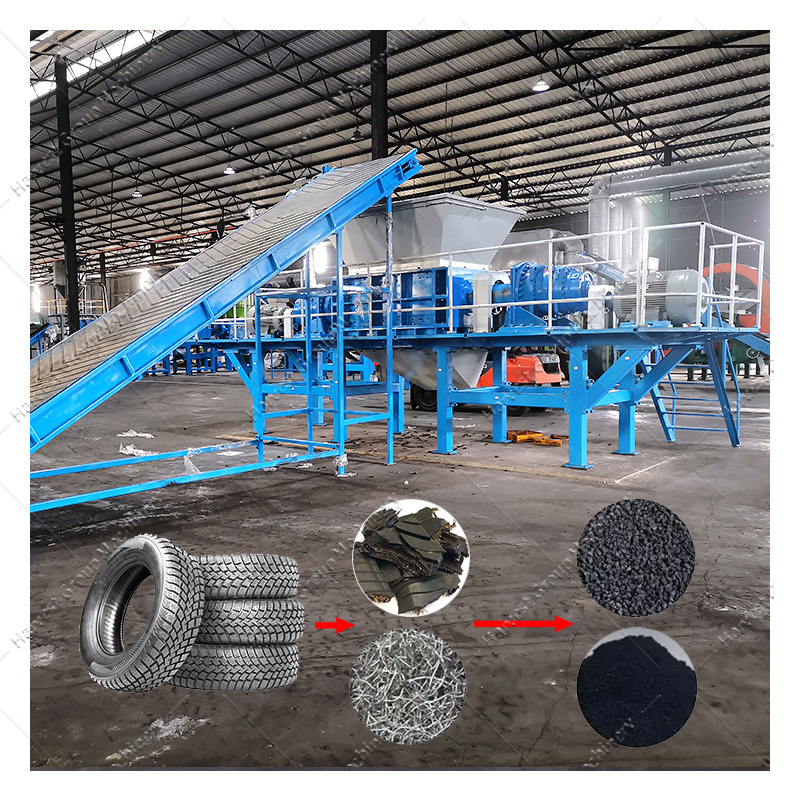

Flow chart of tire recycling

(Fully-automatic Production Line):

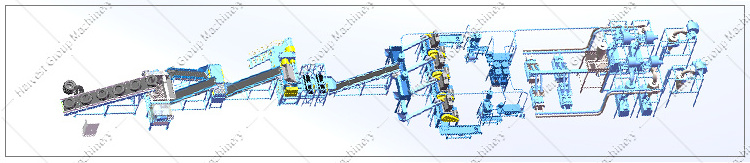

Waste tire - Tire de beader- whole tire cutting - tire shredder - Rubber crushing - magnetic separator - fiber separator - Rubber powder

Flow chart of semi automatic tire recycling line

Whole tire--tire circle cutter--tire strip cutter--tire slice cutter--rubber crusher--Magnetic separator--Nylon fiber separator--rubber powder

Detailed Images

☑

Replaceable blade bit tool is fixed by both screws and grooves on the blade base, so the screws won’t get loosen.

☑ Blades are made one of best material 9Cr2Mo, long service life.

☑

The transmission parts are connected by coupling to reduce vibration and protect the main shaft and reducer from force loss.

☑ Planetary reducer is equipped with high accuracy, high loading power, high speed ratio, durable use, low noise, low vibration and low inertia.

☑ Driven by SIEMENS motor, quality and power guaranteed.

☑

The shredded chips from prime shredder will drop on the rotary screen, and small chips will fall on the conveying belt, the big chips will be feed in the shredder for shredding and recycling again. The final chips will be around 50~60mm.

☑

Super easy operation with buttons and emergency stop functions.

Product Paramenters

Rubber Grinder

Input materials≤50mm tire rubber blocks Finally products ≤20mm. and can remove 96% of the tire steel wire Motor: as per request Reducer: as per request

|

Rasper

|

LK-R315

|

LK-R132

|

LK-R90

|

LK-R75

|

LK-R55

|

LK-R45

|

|||||

|

Motor

|

Siemens

|

Siemens

|

Siemens

|

Siemens

|

Siemens

|

Siemens

|

|||||

|

Power

|

315kw

|

132kw

|

90kw

|

75w

|

55w

|

45kw

|

|||||

|

Voltage

|

As per request

|

As per request

|

As per request

|

As per request

|

As per request

|

As per request

|

|||||

|

Cutting chamber

|

697*1562

|

742*1200

|

550*1000

|

550*800

|

450*800

|

45-*600

|

|||||

|

Equipment dimensions mm

|

6217*2168*3561

|

2010*2562*4110

|

2095*2180*4105

|

1995*1980*4105

|

1720*1730*2316

|

1400*1200*2260

|

|||||

|

Hopper opening

|

1726*877*906

|

1412*902*1410

|

1182*700*1255

|

982*700*1255

|

922*580*916

|

722*580*916

|

|||||

|

Equipment weight

|

24000kg

|

6100kg

|

4200kg

|

3500kg

|

1850kg

|

1700kg

|

|||||

|

Capacity

|

3-6T/H

|

1.5-3T/H

|

1-1.5T/H

|

700KG-1T/H

|

500-700KG/H

|

300-500KG/H

|

|||||

|

Final product

|

10-30mm

|

10-30mm

|

10-30mm

|

10-30mm

|

10-30mm

|

10-30mm

|

|||||

Steel Wire Separator

The rubber grinder is a device that pulverizes 2-6mm pure rubber granules into a fine powder of10-140 mesh at room temperature. Motor: as per request

Product size: one or more sizes are discharged at the same time

|

Granulator

|

LK-G90

|

LK-G45

|

LK-G37

|

LK-R75

|

LK-R55

|

LK-R45

|

|||||

|

Motor specifications

|

Electric-Siemens

|

Electric-Siemens

|

Electric-Siemens

|

Siemens

|

Siemens

|

Siemens

|

|||||

|

Power

|

90kw

|

45kw

|

37kw

|

75w

|

55w

|

45kw

|

|||||

|

Voltage

|

As per request

|

As per request

|

As per request

|

As per request

|

As per request

|

As per request

|

|||||

|

Cutting chamber L*W

|

742*1200

|

580*1000

|

580*800

|

550*800

|

450*800

|

45-*600

|

|||||

|

Equipment Dimensions

|

2150*2250*2950

|

1765*1900*2435

|

1765*1660*2435

|

1995*1980*4105

|

1720*1730*2316

|

1400*1200*2260

|

|||||

|

Equipment weight

|

5600kg

|

3300kg

|

2950kg

|

982*700*1255

|

922*580*916

|

722*580*916

|

|||||

|

Hopper opening L*W*H

|

895*1434*1160

|

602*994*916

|

602*794*916

|

3500kg

|

1850kg

|

1700kg

|

|||||

|

Capacity

|

800-1500kg/h

|

500-800kg/h

|

300-500kg/h

|

700KG-1T/H

|

500-700KG/H

|

300-500KG/H

|

|||||

|

Final product

|

1-6mm

|

1-6mm

|

1-6mm

|

10-30mm

|

10-30mm

|

10-30mm

|

|||||

|

Miller

|

LK-M280

|

|

Motor Specifications

|

Electric-Siemens

|

|

Power

|

30Kw*4

|

|

Voltage

|

as per request

|

|

Equipment Dimensions L*W*H

|

2404*1100*1093

|

|

Equipment Weight

|

5000Kg

|

|

Capacity

|

400-600kg/hr

|

|

Final Product

|

30-120 mesh

|

Customer feedback

Why Choose Us

Zhengzhou Harvest Machinery Co., Ltd

HVET's main focus is to provide our customer cost-effective waste recycling system applied in all kinds of waste recycling like tire/plastic/wood/metal/car/pcb board recycling and could provide output products like chips(50-150mm), mulches( 10-30mm), granules (1-6mm), powder (30-120 mesh) and other size as customer required. HVET also offers machines for specialized markets. The most important to theHVET family of products is the Tire Shredding System. These machines are designed to process used car and truck tires. We offer complete systems to produce separated crumb or powder.

Customer Site

FAQ

1. who are we?

We are based in Henan, China, start from 2013,sell to South America(20.00%),Africa(20.00%),Southeast Asia(20.00%),North America(10.00%),Western Europe(10.00%),Eastern Europe(10.00%),Mid East(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Waste Tire Recycling Machine/Rubber Crusher/Tire Shredder/Tire Crusher/E-waste Recycling/Metal Shredder/Plastic Recycling/Cable Wire Recycling/Wood Shredder, Waste Tire Recycling Machine/Metal Shredder/PCB Recycling/Copper Wire Recycling/Plastic Recycling/Wood Shredder

4. why should you buy from us not from other suppliers?

1.Our factory established in 1987, With nearly 30 years experience 2. All machines are 2 years warranty 3. Competitive price with high quality 4.We got SGS inspection certificate and CE certificate 5. Factory visited is welcomed

5. what services can we provide?

Accepted Delivery Terms: FOB,EXW;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,Western Union,Cash;

Language Spoken:English,Chinese,Arabic,Korean

We are based in Henan, China, start from 2013,sell to South America(20.00%),Africa(20.00%),Southeast Asia(20.00%),North America(10.00%),Western Europe(10.00%),Eastern Europe(10.00%),Mid East(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Waste Tire Recycling Machine/Rubber Crusher/Tire Shredder/Tire Crusher/E-waste Recycling/Metal Shredder/Plastic Recycling/Cable Wire Recycling/Wood Shredder, Waste Tire Recycling Machine/Metal Shredder/PCB Recycling/Copper Wire Recycling/Plastic Recycling/Wood Shredder

4. why should you buy from us not from other suppliers?

1.Our factory established in 1987, With nearly 30 years experience 2. All machines are 2 years warranty 3. Competitive price with high quality 4.We got SGS inspection certificate and CE certificate 5. Factory visited is welcomed

5. what services can we provide?

Accepted Delivery Terms: FOB,EXW;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,Western Union,Cash;

Language Spoken:English,Chinese,Arabic,Korean

Hot Searches