- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

PUstar

-

Model Number:

-

Renz50

-

Type:

-

One Component

-

Application:

-

After market of auto

-

Feature:

-

Excellent bonding performance, primer-less

-

Appearance:

-

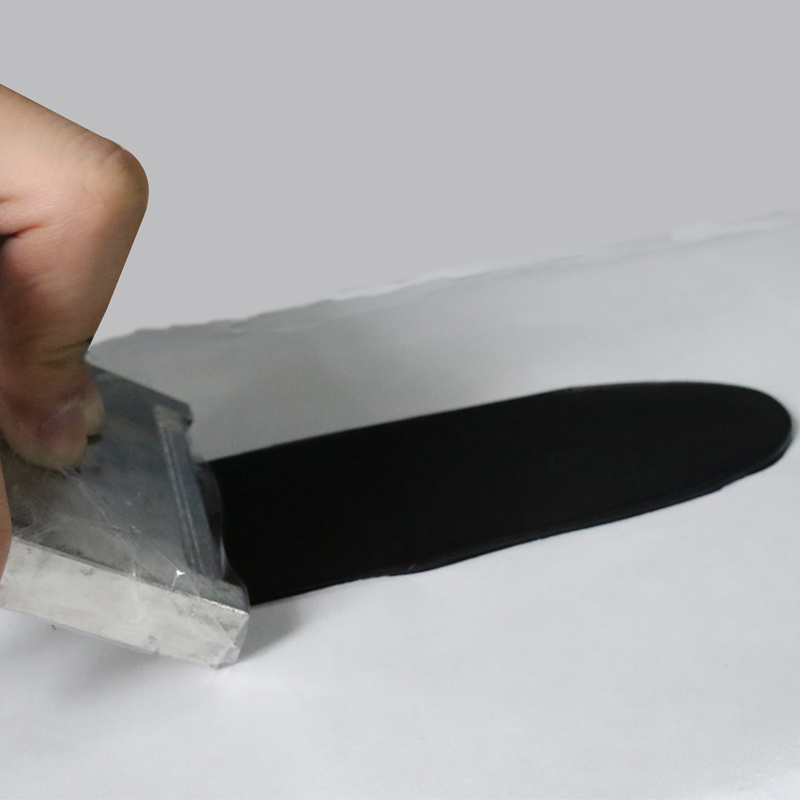

Black homogeneous paste

-

Shelf life:

-

9 Months

-

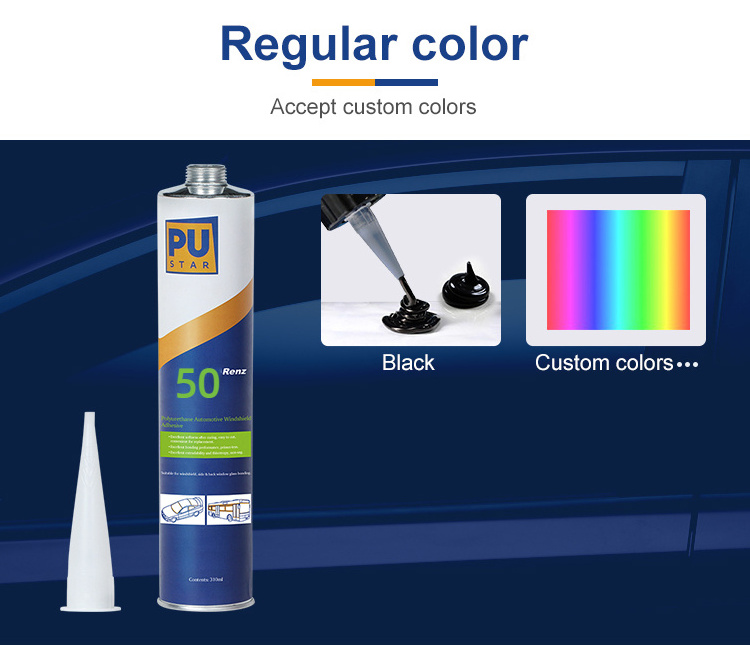

Color:

-

Black

-

Certificate:

-

ISO9001 / IOS/TS 16949/2009

-

Volume:

-

310ml/ 400ml /600ml

-

Free sample:

-

Available

-

Delivery time:

-

10~20 Days

Quick Details

-

CAS No.:

-

refer to MSDS

-

Other Names:

-

automotive sealant

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

PUstar

-

Model Number:

-

Renz50

-

Type:

-

One Component

-

Application:

-

After market of auto

-

Feature:

-

Excellent bonding performance, primer-less

-

Appearance:

-

Black homogeneous paste

-

Shelf life:

-

9 Months

-

Color:

-

Black

-

Certificate:

-

ISO9001 / IOS/TS 16949/2009

-

Volume:

-

310ml/ 400ml /600ml

-

Free sample:

-

Available

-

Delivery time:

-

10~20 Days

High Grade Polyurethane Windshield Adhesive

Renz-50 is High strength modified silane bonding sealant.

Technical Date

|

Renz 50

High Strength Modified .Silane Bonding Sealant

|

|

|

||

|

Items

|

Standard

|

Standard

|

||

|

Appearance

|

Black, homogeneous paste

|

/

|

||

|

Dencity GB/T 13477.2

|

1.45±0.1

|

1.50

|

||

|

Extrudability(ml/min) GB/T 13477.4

|

≥200

|

220

|

||

|

Sagging properties (mm) GB/T 13477.6

|

≤0.5

|

0

|

||

|

Tack free time (min) GB/T 13477.5

|

10~60

|

20

|

||

|

Curing speed (mm/d) HG/T 4363

|

≥3.0

|

3.5

|

||

|

Volatile contents (%) GB/T 2793

|

≥97

|

98

|

||

|

Shore A hardness GB/T 531.1

|

45~55

|

50

|

||

|

Tensile strength (MPa) GB/T 528

|

≥2.5

|

3.0

|

||

|

Elongation at break(%) GB/T 528

|

≥400

|

420

|

||

|

Operating temperature(℃)

|

-40~90

|

-40~90

|

||

①All data above were tested under standardized condition at 23±2℃, 50±5%RH.

② Value of tack free time would be affected by change of environmental temperature and humidity.

Products Images

Packaging Information

Hot Searches