- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380 V or other require

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

configure

-

Weight:

-

3000 kg

-

Marketing Type:

-

New Product 2022

-

Certification::

-

ce

-

After-sales service provided:

-

ree spare parts, on-site installation, commissioning and training.

-

Machine type:

-

ordinary eight-sided rotary egg tray machine

-

Raw material:

-

waste paper

-

Color:

-

optional

-

Finished product:

-

egg tray, paper tray

-

Frequency:

-

50 Hz

-

Drying method:

-

earth drying tunnel or iron box drying

-

Forming machine pulp concentration:

-

0.8-1%

Quick Details

-

Production Capacity:

-

60-70 pcs/min, 30 set/month

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SF

-

Voltage:

-

220V/380 V or other require

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

configure

-

Weight:

-

3000 kg

-

Marketing Type:

-

New Product 2022

-

Certification::

-

ce

-

After-sales service provided:

-

ree spare parts, on-site installation, commissioning and training.

-

Machine type:

-

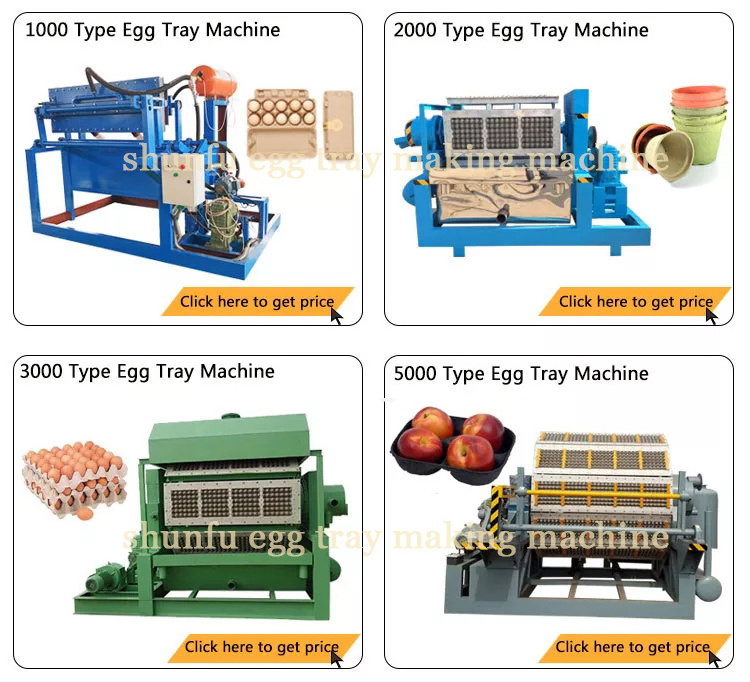

ordinary eight-sided rotary egg tray machine

-

Raw material:

-

waste paper

-

Color:

-

optional

-

Finished product:

-

egg tray, paper tray

-

Frequency:

-

50 Hz

-

Drying method:

-

earth drying tunnel or iron box drying

-

Forming machine pulp concentration:

-

0.8-1%

Product Description

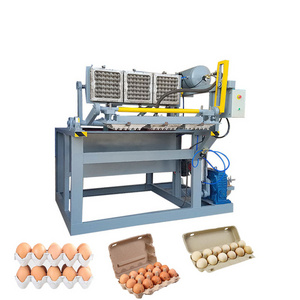

Small egg tray wasted paper recycling no pollution egg tray making machine

Egg tray machine is a general term for machines that manufacture pulp and egg trays for conveying eggs over long distances. Egg tray machine is a specialized production equipment for egg trays, bottle trays and other pulp molding products.

Specification

|

Machine type

|

8 sides rotary egg tray machine (4*8)

|

|

Raw material

|

Waste paper

|

|

Production varieties

|

Egg tray, paper tray

|

|

Production speed

|

3500-4500 pieces/ hour

|

|

Total power

|

156KW (Intermittent use)

|

|

Pulp concentration for molding machine

|

0.8-1%

|

|

Pressure of compressed air

|

0.5-0.7Mpa

|

|

Vacuum negative pressure

|

minus 0.035--- minus 0.045Mpa

|

|

Voltage

|

380 V

|

|

Frequency

|

50 z

|

Features:

1. Fully automatic operation according to the setting paper egg tray machine.

2. The world-renowned electrical appliance brand makes the egg tray machine run stably.

3. Adopt new process optimization design to form an efficient paper egg tray machine.

4. Perfect fault detection system and motor protection system to ensure safe operation.

Production Process

The raw materials of the waste carton are pulped, and then mixed with pulp. After screening, the pulp is supplied to the egg tray machine for forming and drying. Natural drying and metal drying can be selected, and finally packaged.

Hot Searches