- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3*4*12m

-

Weight:

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

candle machine making

-

Product name:

-

Automatic Birthday Candle Production Line

-

Type:

-

Handle

-

Material:

-

Steel

-

Capacity:

-

1200pcs Candle

-

Application:

-

Raw Wax

-

Color:

-

Customer Requirement

-

Candle Size:

-

Candle Size Selectable

-

Model:

-

Model Differ

Quick Details

-

Place of Origin:

-

shanghai

-

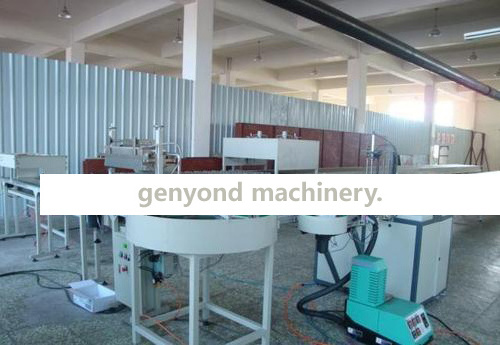

Brand Name:

-

genyond

-

Production Capacity:

-

5000

-

Dimension(L*W*H):

-

3*4*12m

-

Weight:

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

candle machine making

-

Product name:

-

Automatic Birthday Candle Production Line

-

Type:

-

Handle

-

Material:

-

Steel

-

Capacity:

-

1200pcs Candle

-

Application:

-

Raw Wax

-

Color:

-

Customer Requirement

-

Candle Size:

-

Candle Size Selectable

-

Model:

-

Model Differ

Features

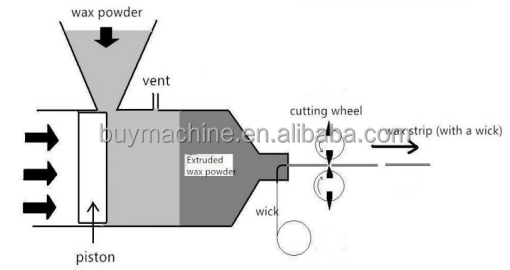

2. It is easy and quick to change the diameter, length and shape of the candle head.

3. Simultaneous extrusion of the wick and the candle can control the tightness of the wick to ensure the burning time

and burning stability of the candle.

4. With production metering function, you can check the output at any time.

5. Adopting plunger hydraulic system, PLC command programming reciprocating automatic operation, frequency

conversion regulation and trimming, the overall equipment operation is stable and reliable.

Raw materials and equipment

Production candle wax are the main raw materials, auxiliary materials is stearic acid, trace raw material with beeswax, essence, pigment and metal salt and so on, the production of the candle machine is the candle machine, there are 10, 20, 40, 50, 60, 70, 80 type, 90 type, 100 type, 120 type, etc., each single lays a candle for 10, 20, 40, 50, 60, 70, 80, 90, 100, 120, etc.

Production methods

Put the paraffin, stearic acid and trace chemicals together in the aluminum pot melting, pouring into the pre-coated oil and has been matched with the candle wick in the machine model, pouring into, first fill the water tank of the candle machine with cold water, and make it circulation, promote its condensation. After condensation, cut the candle wick.

Ordinary white candles require no toppings and are made from paraffin wax at about 55 degrees. With the development of science and technology, no black smoke, no tears, no dust, combustion resistance, brightness candles, summer unchanged soft, not bending candles, drive mosquitoes candles, scented candles, process candles, colored candles, colored flame candles and other colorful candles should be far and living.

|

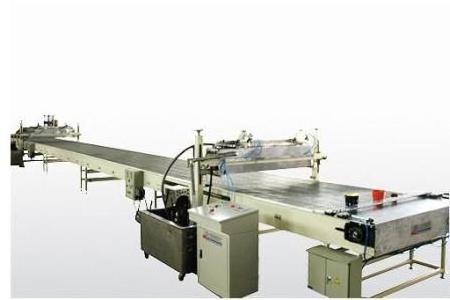

Diameters

|

12-50 mm

|

|

Lengths

|

100-350 mm

|

|

Capacity(single side)

|

6000 candles/hour

|

|

Capacity(double side)

|

12000 candles/hour

|

|

Main machine power

|

22 kw

|

|

Part machine power

|

6.8 kw

|

|

Dimensions

|

5800×7600×3000(mm)

|

|

Weight

|

4600 kgs

|